Mounting structure of automobile instrument liquid crystal screen

A technology for automobile instrumentation and installation structure, which is applied to instruments, identification devices, vehicle parts, etc., and can solve the problems of sensitivity, uneven dark state, and uneven dark state of LCD screen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

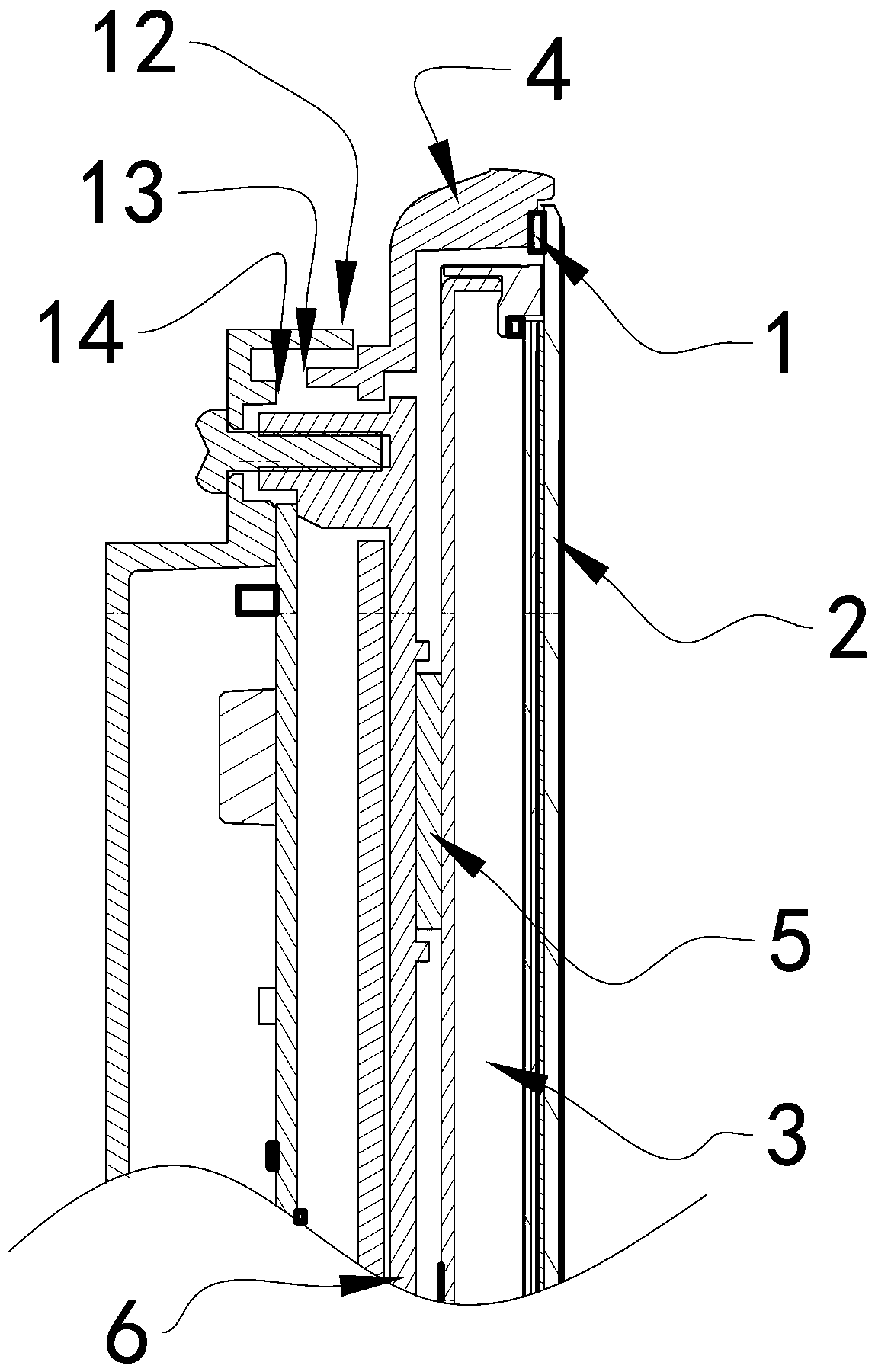

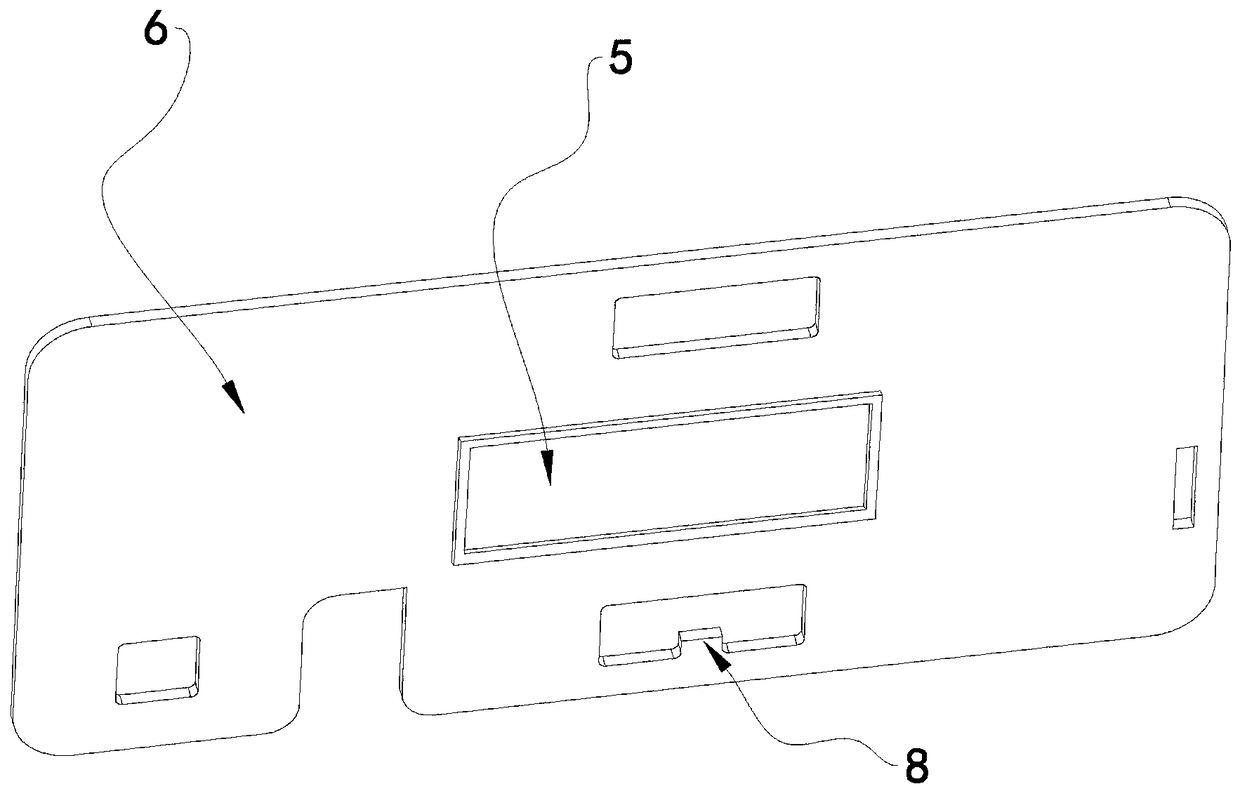

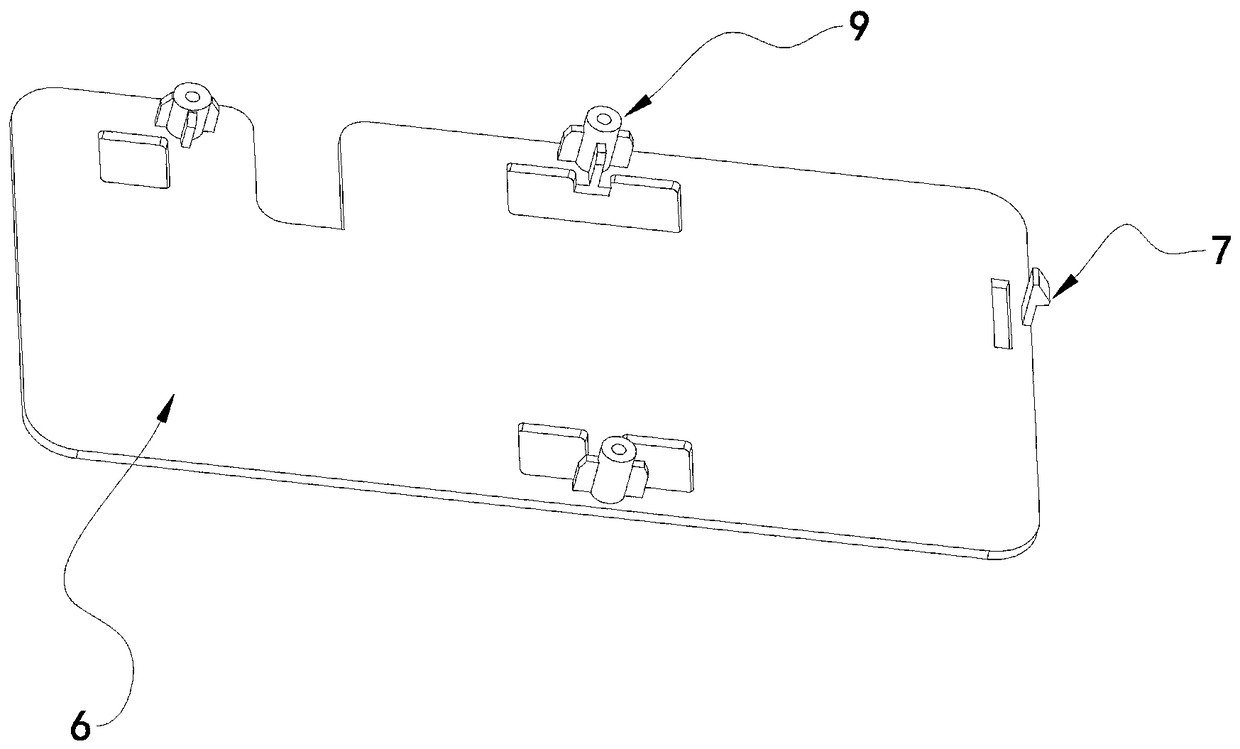

[0012] An installation structure of an automotive instrument LCD screen, comprising a front case, a rear case and a connecting plate, the front and rear cases are connected through a connecting plate 6; glass is installed on the outside of the front case 4, and the liquid crystal screen 3 is installed on the front case and the connecting plate Between them, the front side is bonded to the surroundings of the glass 2 through the shockproof gaskets around; A flexible arc-shaped plate is arranged around, and is connected with the connecting plate through the arc-shaped plate, and the screw passes through the screw hole and is screwed into the nut column to connect the back shell with the connecting plate.

[0013] The vibration generated when the car is running is transmitted to the rear shell, and the vibration of the rear shell causes the resonance of the screw and the nut column, and the arc plate connected by the nut column absorbs the vibration through its own deformation. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com