Method for reinforcing cracked and damaged lining of operation tunnel

A technology of lining and crack damage, which is applied in the direction of tunnel lining, tunnel lining, shaft lining, etc., can solve the problems of high construction cost, large impact on tunnel operation, frequent falling off of sprayed materials, etc., and achieve the effect of small economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

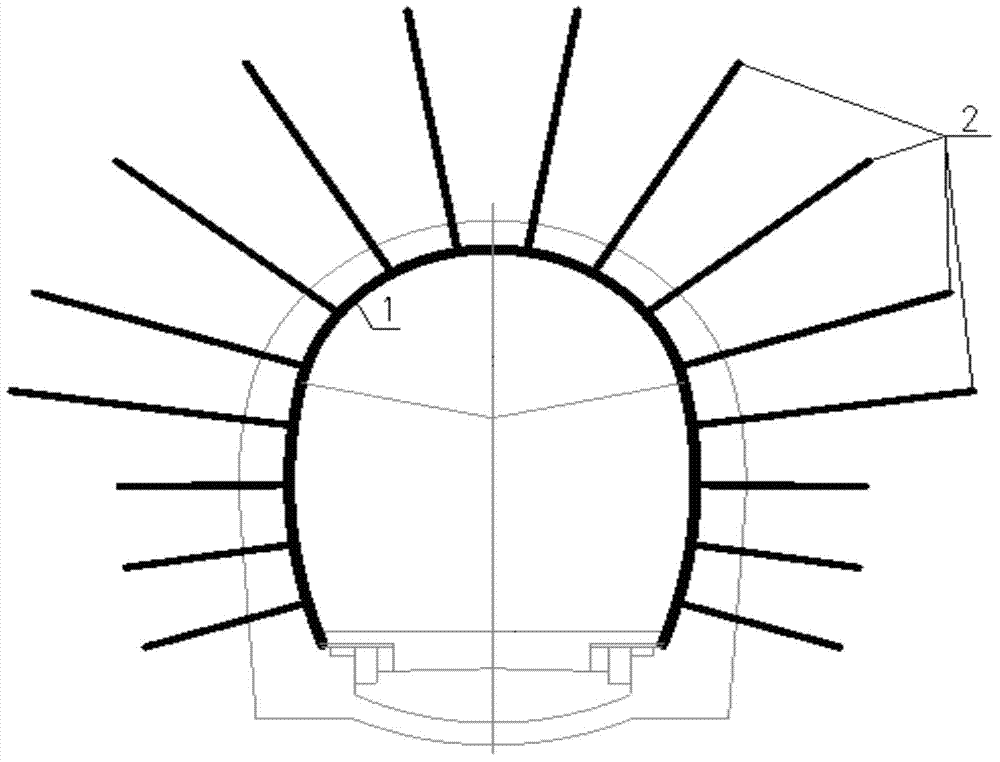

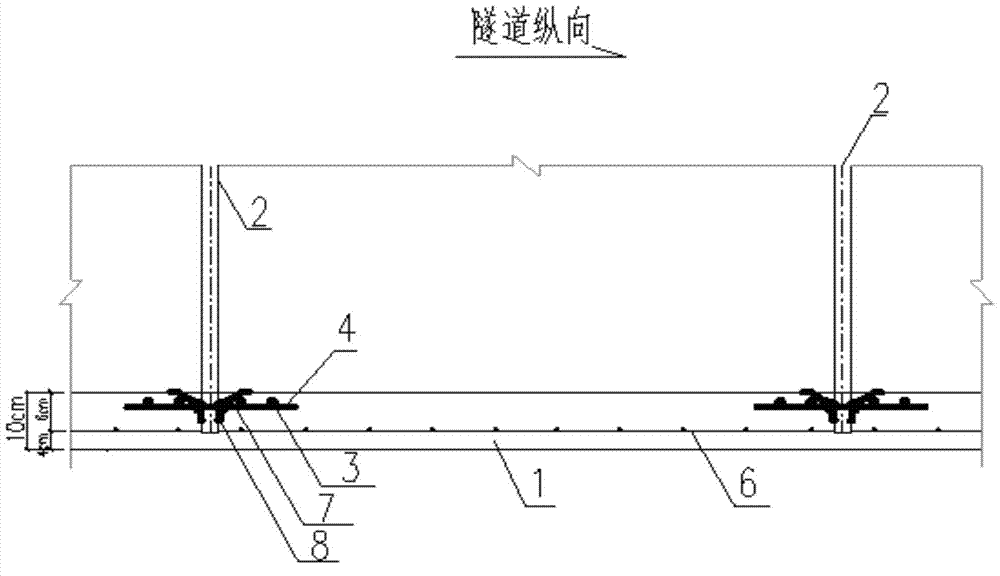

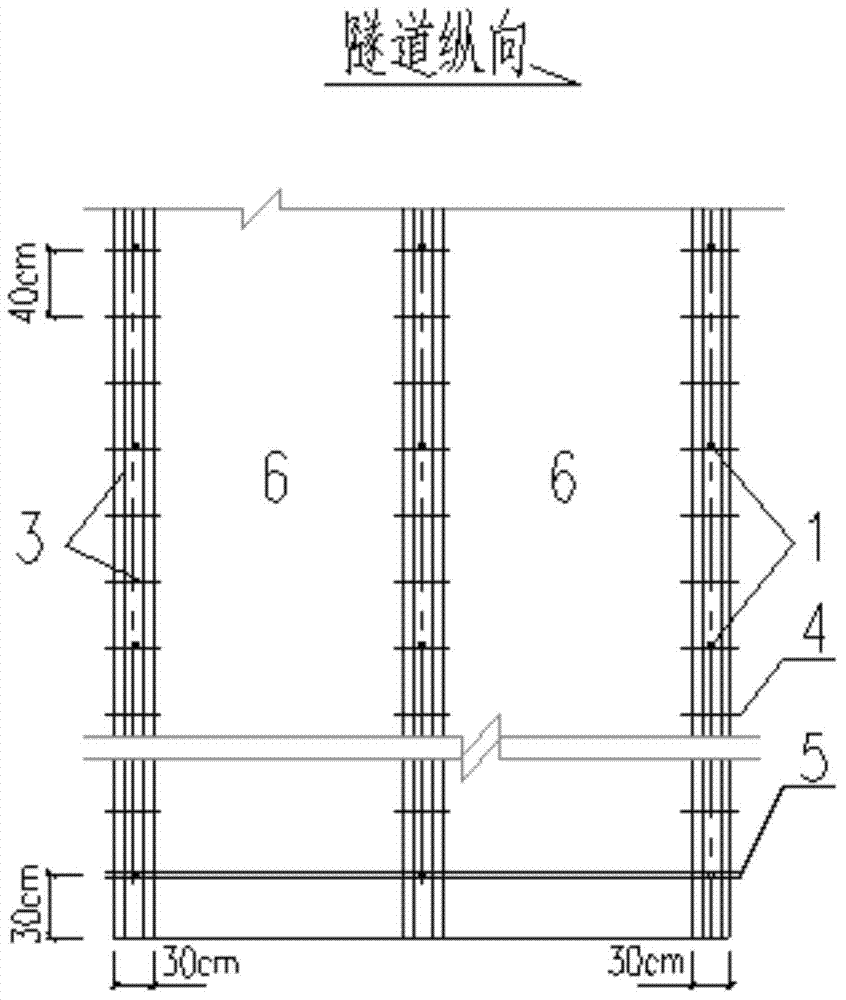

[0030] see figure 1 , figure 2 and image 3 , the method for reinforcing and reinforcing the cracked lining of the operating tunnel provided by the present invention, the cracked lining is reinforced by using anchor rods, steel mesh, ribbed steel bars, and shotcrete, and the lining and surrounding rock are integrated to improve the lining structure. The overall stability of the system includes the following steps:

[0031] a. Clean the lining surface: remove impurities such as decorative layers, oil stains, and floating dust on the concrete surface;

[0032] b. Judgment of headroom: According to the measurement data and limit size of the headroom section, for the part with insufficient headroom, the lining shall be properly chiseled to ensure that the sprayed concrete does not invade the limit after covering;

[0033] c. Con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com