Production technology of thin elastic cotton and polyester interwoven fabric

A production process, cotton-polyester technology, applied in the field of production process of light and thin cotton-polyester elastic interwoven fabrics, can solve the problems of elasticity and shrinkage instability, uneven fabric first-class product rate, increased production costs, etc., to prevent weft shrinkage, Reduce weft shrinkage and increase clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The production process of C40S×T75D / 40D×133×70 cotton-polyester elastic poplin (dyed cloth), which includes steps in turn: material preparation → pre-preparation → weaving → gray fabric repair → fabric turning → singeing → desizing → oxygen bleaching → Shaping→mercerizing→dyeing→finishing; the preparations include cotton, polyester-spandex covered yarn processed from polyester and spandex, the warp direction is 40S high-count cotton, and the weft direction is T75D low-stretch yarn and 40D spandex bag Preparation of raw materials for covering wire (inline and written as T75D / 40D).

[0023] The pre-preparation: according to the variety specifications and process requirements: the warp yarns are sized and made into weaving beams→drawing; usually the weft yarns can be directly loaded on the machine.

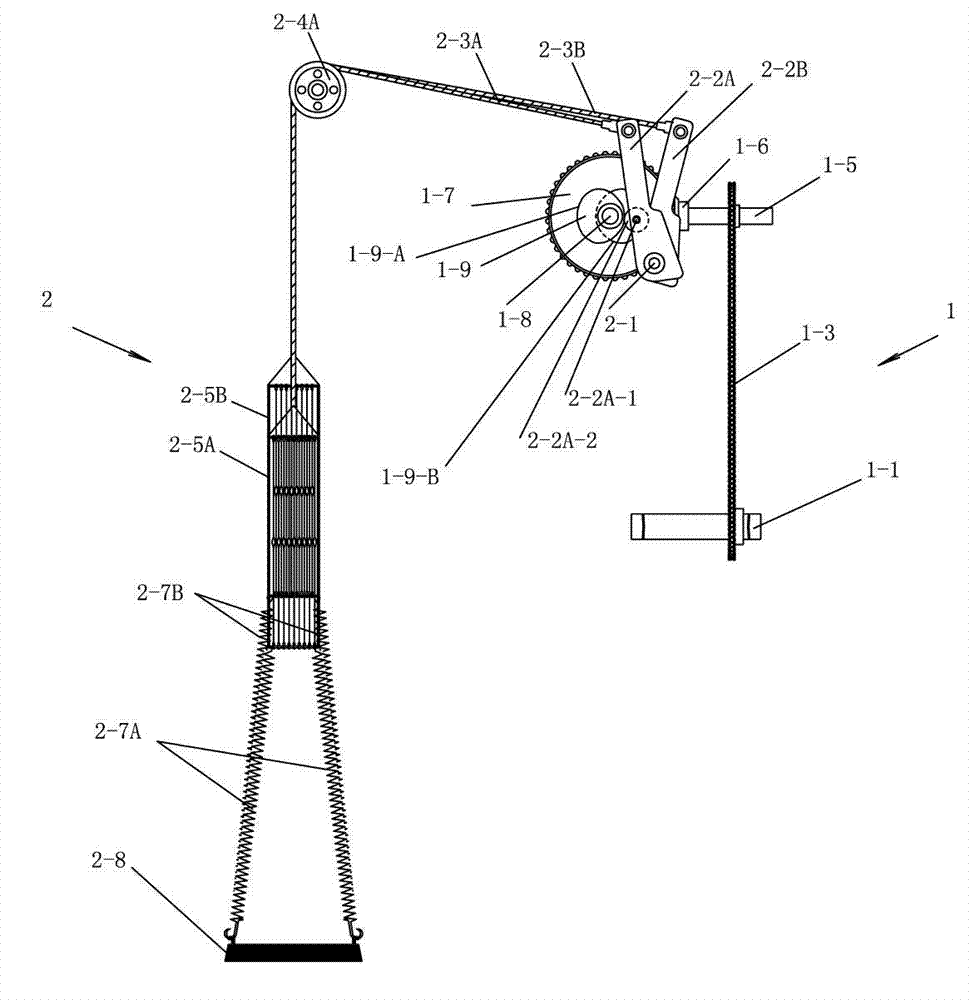

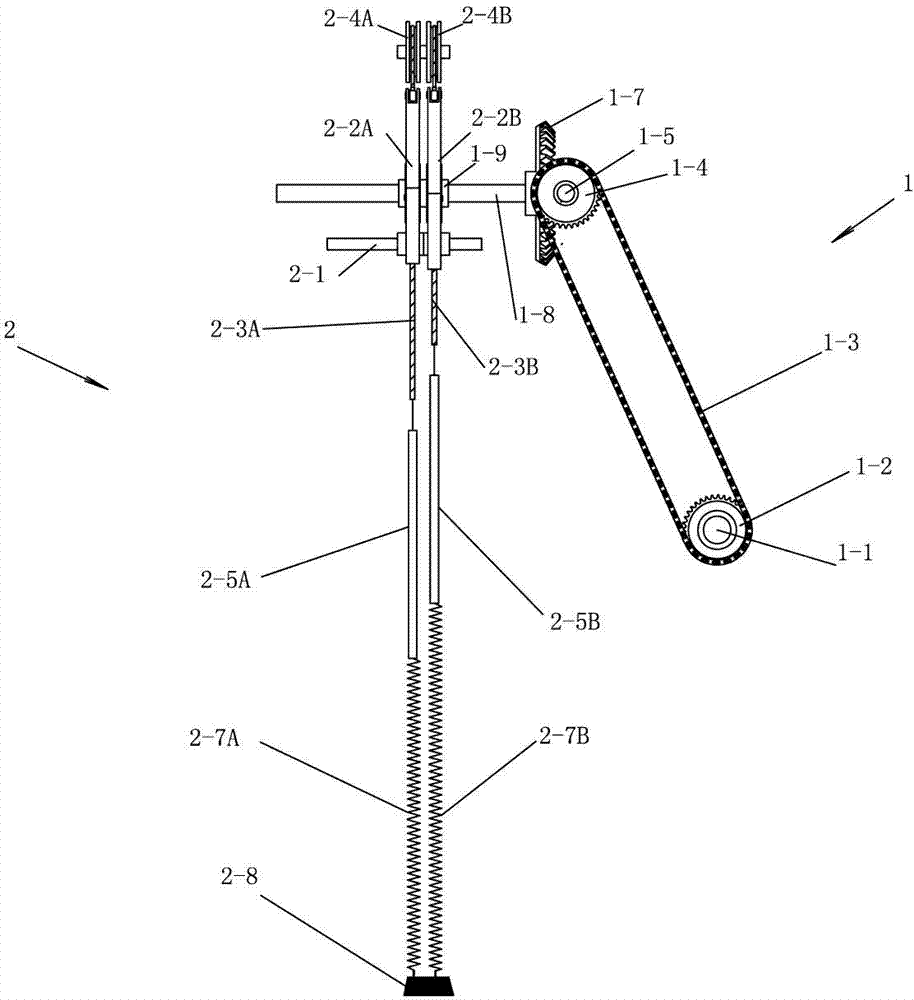

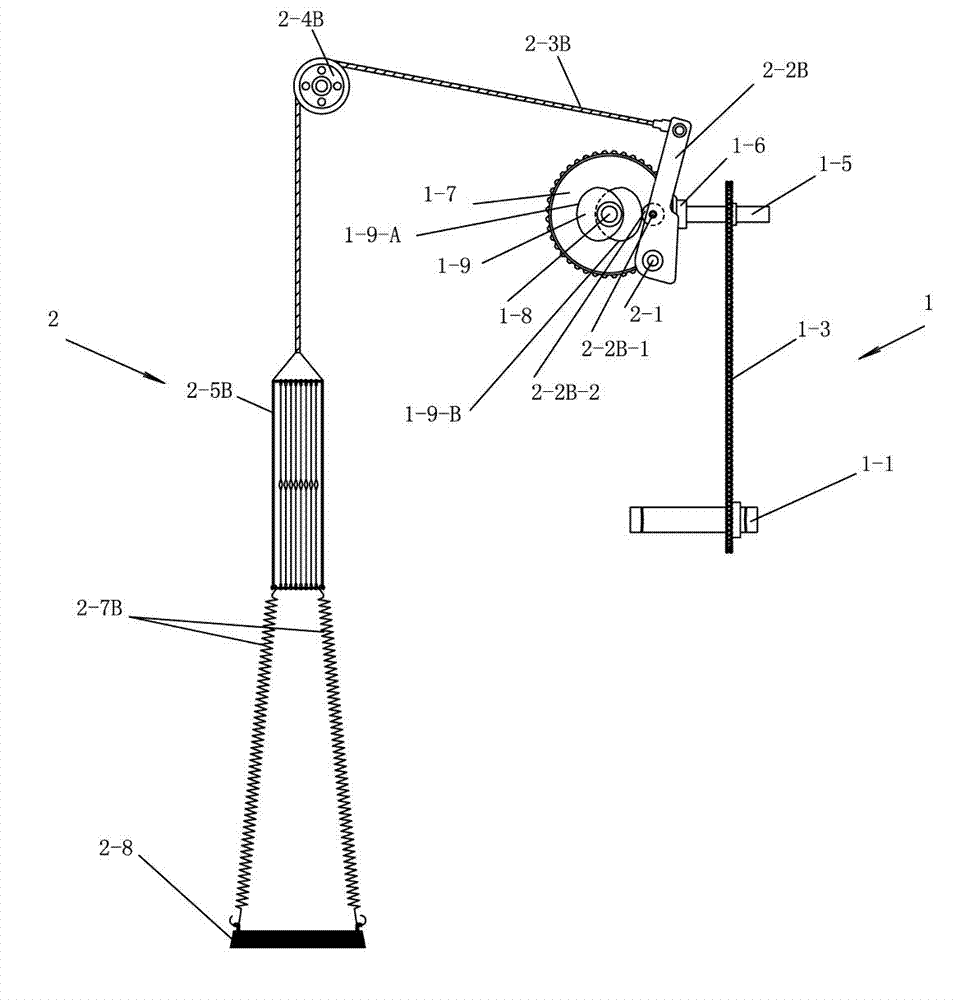

[0024] See attached figure 1 , attached figure 2 , attached image 3 , the weaving is installed on the loom by the weaving beam that is ready to wear the harness before we...

Embodiment 2

[0043] The production process of C50S×T50D / 25D×160×80 cotton-polyester elastic poplin (dyed fabric) includes steps in turn: material preparation → pre-preparation → weaving → gray fabric repair → fabric turning → singeing → desizing → shaping → mercerizing → finishing ;

[0044] The preparation materials include cotton, polyester-spandex-coated yarn processed from polyester and spandex, the warp direction is 50S high-count cotton, and the weft direction is T50D low-stretch yarn and spandex-coated yarn composed of 25D (also can be written as T50D / 25D ) for raw material preparation.

[0045] Pre-preparation: Calculate the warp and weft yarns and the required amount of each color according to the variety specifications and process requirements, and then carry out dyeing in the cross-dyeing factory. The warp yarns are arranged according to the technical requirements and made into weaving beams through sizing → drawing in heddles; the weft yarns are usually dyed and can be directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com