Pipe packaging technology

A packaging technology and pipe technology, which is applied in the field of pipe packaging technology, can solve the problems of poor packaging effect, oil leakage, low efficiency, etc., and achieve the effects of preventing pipe damage, ensuring packaging effect, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

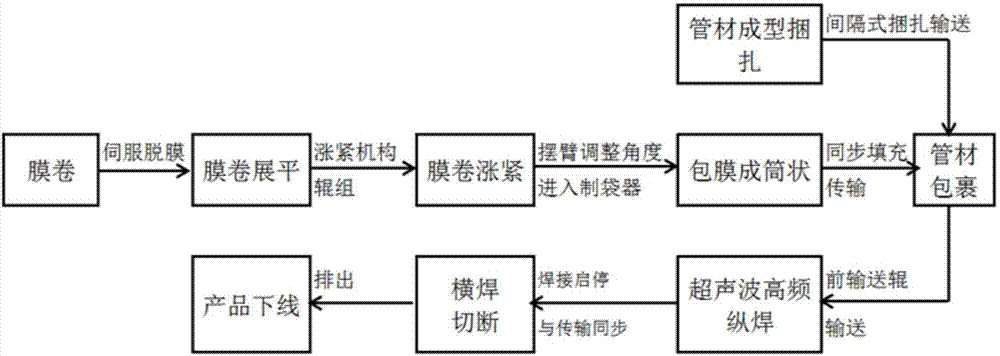

[0016] Such as figure 1 Shown, a kind of pipe packaging process, the steps are as follows:

[0017] Step 1, pipe forming and bundling; the pipes are automatically sorted by a pipe finishing machine, and the pipes are bundled by a strapping machine, and the bundled pipes are ready to enter the next step.

[0018] Step 2, pipe wrapping; the pipe in step 1 is preliminarily packed by a pipe packaging machine. Among them, the working steps of the tube packaging machine are: firstly, the packaging film in the film roll is servo-released, and then the released packaging film is tensioned by the roller set of the tensioning mechanism, and then the angle of the swing arm is adjusted to enter the manufacturing process. In the bag machine, the packaging film is made into a tube, and is synchronously transferred to the packaging machine to realize the preliminary packaging of the packaging film and the tube.

[0019] Step 3, ultrasonic high-frequency longitudinal welding; use the ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com