A small high-precision five-axis CNC machine tool

A CNC machine tool, B-axis technology, applied in the direction of large fixed members, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of poor rigidity of machine tools, complex spindle drive, etc., to improve precision, simplify manufacturing and installation process, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

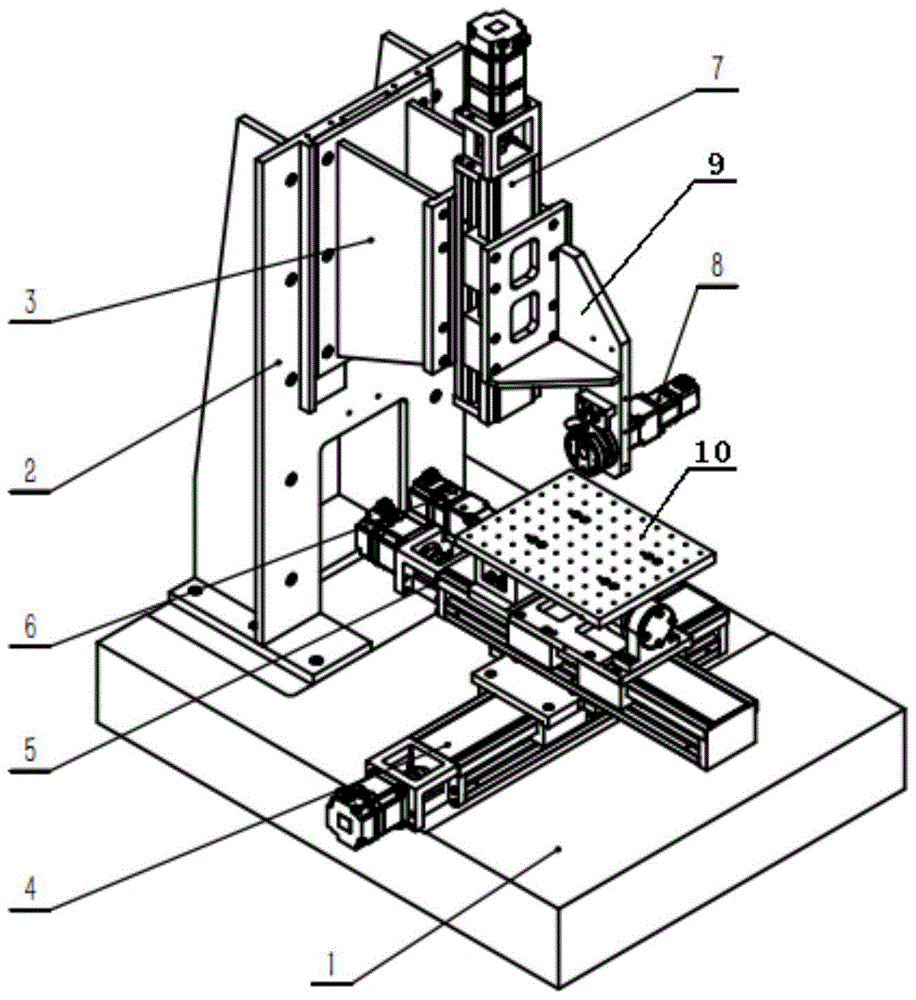

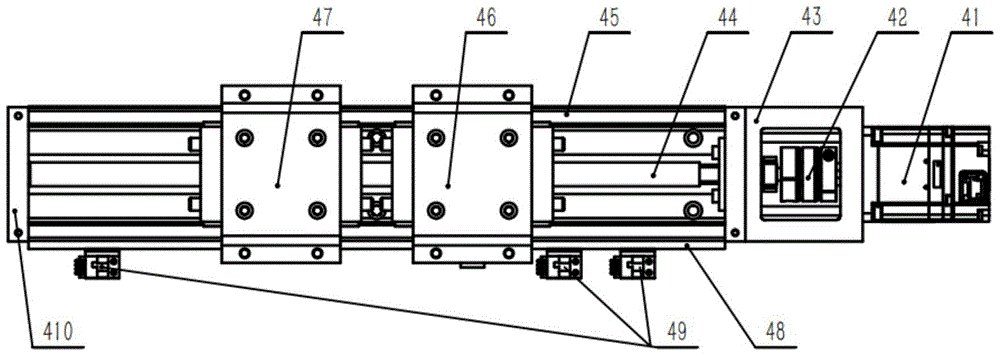

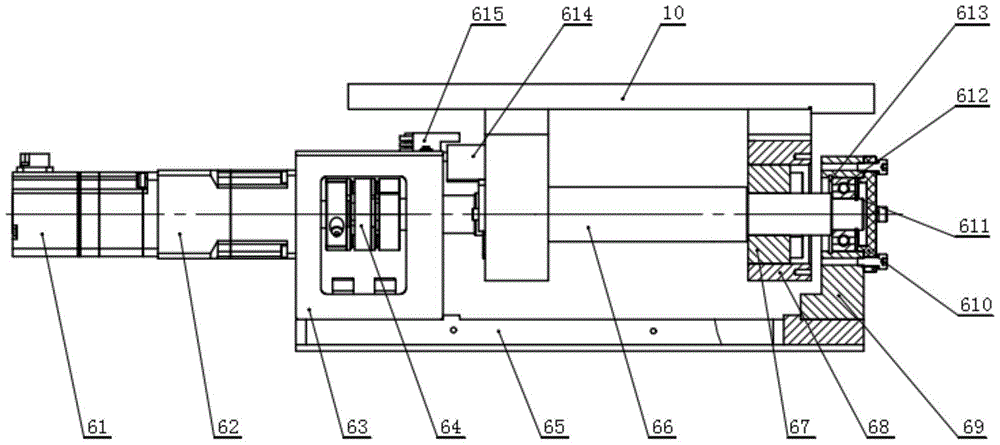

[0031] figure 1 It is a perspective view of a five-axis CNC machine tool according to an embodiment of the present invention; figure 2 for figure 1 Schematic diagram of the structure of the Y-axis moving assembly of the five-axis CNC machine tool shown; image 3 for figure 1 Schematic diagram of the structure of the A-axis swing assembly of the five-axis CNC machine tool shown; Figure 4 for figure 1 Schematic diagram of the structure of the B-axis swing assembly of the five-axis CNC machine tool shown.

[0032] Such as figure 1 As shown, the five-axis CNC machine tool of this embodiment includes a base 1 and a Z-axis support 2 installed on the base 1. The Y-axis moving assembly 4 and the X-axis moving assembly 5 on the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com