Network tube type natural gas drying device

A drying device and natural gas technology, applied in the direction of gas fuel, petroleum industry, dispersed particle separation, etc., can solve the problems of adsorbent failure, high frequency of adsorbent replacement, short use time, etc., to reduce the amount of water vapor and improve drying effect, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

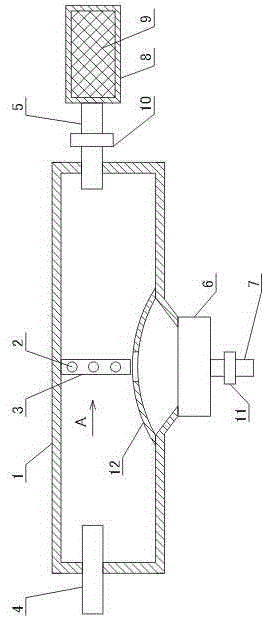

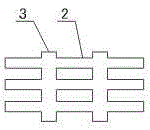

[0025] Such as figure 1 with figure 2 As shown, the network tube type natural gas drying device includes a drying chamber 1, a horizontal condensation pipe 2, a vertical condensation pipe 3, an air inlet pipe 4, an air outlet pipe 5, a liquid collection box 6, a liquid outlet pipe 7, a drying pipe 8 and an adsorbent 9; The bottom of the drying chamber 1 is provided with a tapered opening, the liquid collection box 6 communicates with the tapered opening, the horizontal condensation pipe 2 and the vertical condensation pipe 3 are arranged crosswise, the horizontal condensation pipe 2 and the vertical condensation pipe 3 communicate with each other, and the horizontal condensation pipe 2 and the vertical condensation pipe 3 are connected to each other. The vertical condensation pipe 3 is arranged in the drying chamber 1 and above the tapered opening; the air inlet pipe 4 is arranged on the left side of the drying chamber 1, the air outlet pipe 5 is arranged on the right side of...

Embodiment 2

[0029] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment further includes a second shut-off valve 11 disposed on the air outlet pipe 5 .

[0030] A second shut-off valve 11 is provided. When the natural gas is not being dried, the second shut-off valve 11 is closed to prevent the condensed water in the liquid collection box 6 from evaporating into the drying pipe 1, further improving the service life of the adsorbent.

Embodiment 3

[0032] Such as figure 1 As shown, on the basis of Embodiment 1 or 2, this embodiment also includes an arc-shaped plate 12 arranged in the drying chamber 1 shown, the arc-shaped plate 12 protrudes upwards, and the arc-shaped plate 12 is located in the tapered opening shown Above, the arc-shaped plate 12 is provided with an opening at the part directly below the horizontal condensing pipe 2 and the vertical condensing pipe 3 .

[0033] The arc-shaped plate 12 can change the flow direction of the natural gas, preventing the natural gas from entering the liquid collection box 6 and bringing in water vapor again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com