Deep control method and deep control device of pollutant in burning gas of ethane cracking furnace

An ethylene cracking furnace and deep control technology are applied in the purification and treatment of particulate pollutants and malodorous pollutants. The field of devices used to implement the method can solve the problems of inability to effectively control PM2.5 fine particle pollutants and inability to do anything about malodorous pollutants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A certain domestic ethylene plant adopted the device of this application.

[0060] Process flow:

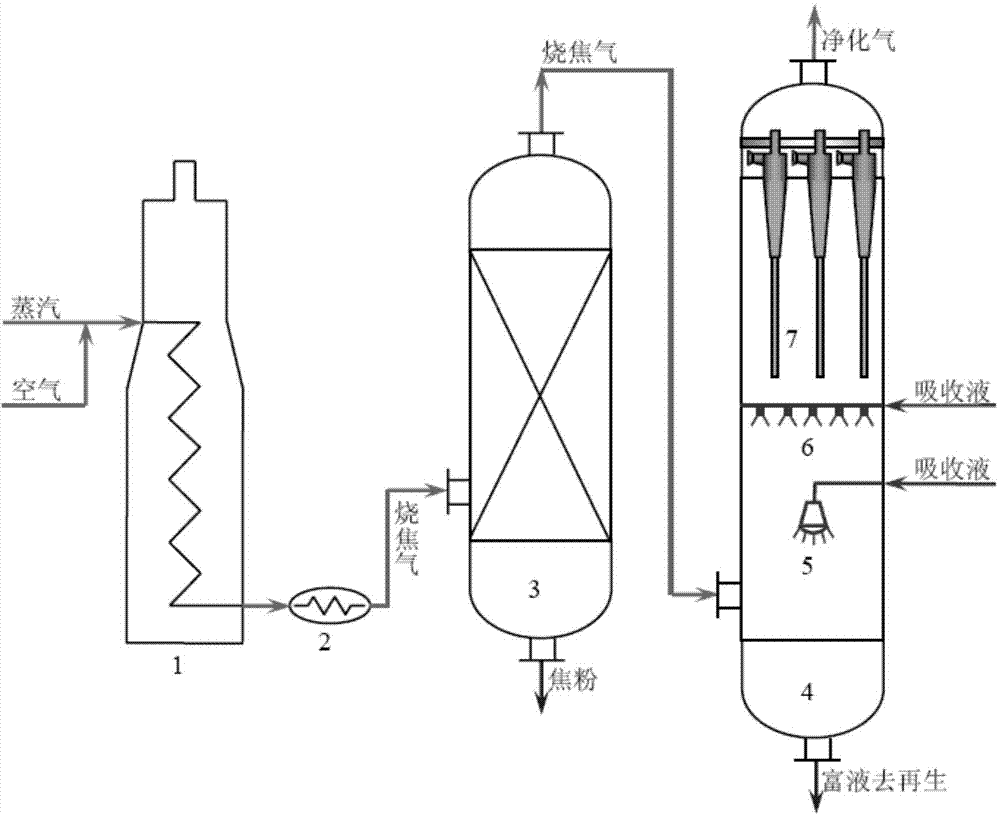

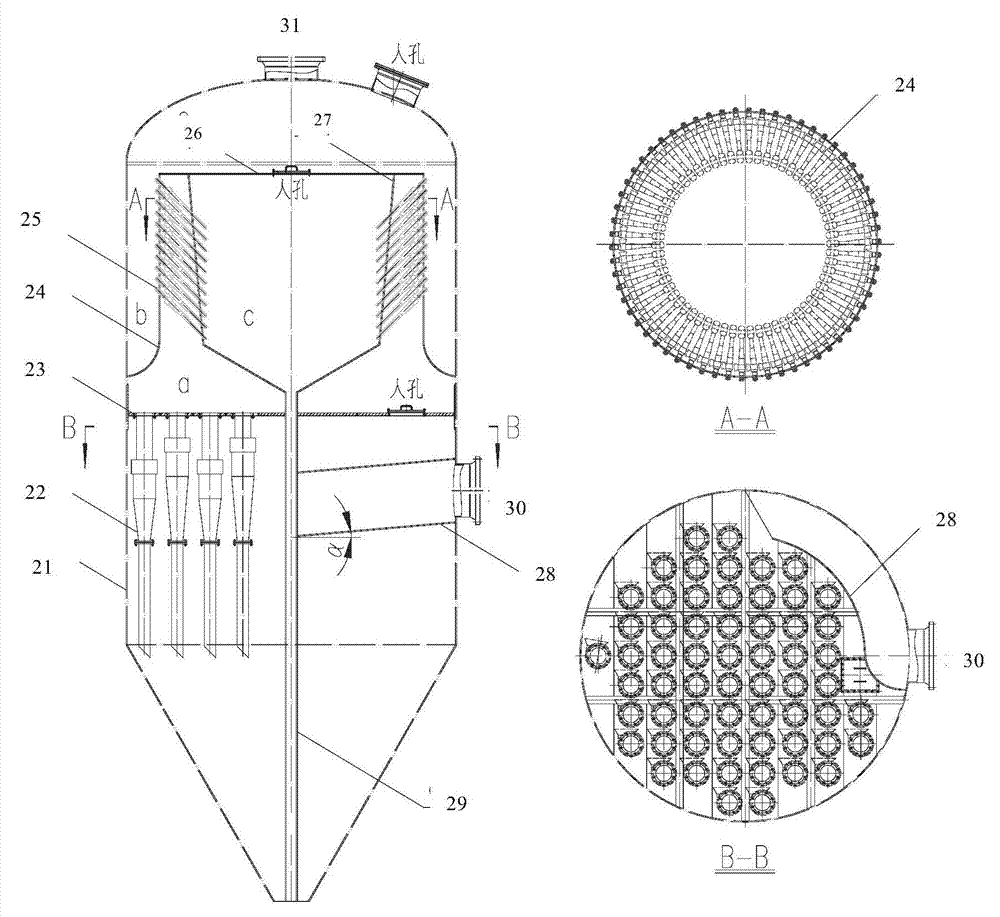

[0061] Such as figure 1 shown.

[0062] Two-stage micro-cyclone separation is performed on the coke gas of the ethylene cracking furnace to remove coke powder and rust entrained in the gas; spray washing is performed on the coke gas desolidified by the two-stage cyclone to initially absorb and cool the gas odorous pollutants entrained in the air; the charred gas enters the micro-swirl absorber for deep absorption and cooling of the odorous pollutants and efficient separation and recovery of the absorbed rich liquid and odorous pollutant condensate; The absorbed rich liquid is regenerated for recycling.

Embodiment approach

[0064] After the cracking furnace of the ethylene plant is burnt online and after the burn is completed, it needs to go through the steam heat standby stage. At this time, the medium of the charred gas pipeline is diluted steam. After the cracking furnace is switched, the scorched pipeline is cooled during operation and scorched due to steam condensation The inner surface of the gas pipeline is corroded and rusted. When the pyrolysis furnace is scorched, especially during the switching of the cracking gas valve, the yellow-brown rust in the pipeline is easily discharged from the charred gas discharge chimney along with the large amount of steam, and adheres to the nearby steel structure, causing The scorched gas turns yellow. In addition, a large amount of coke powder particles are entrained in the coke gas, which makes the gas color black. In addition, about 1000 mg / m is also entrained in the gas 3 Odor pollutants, resulting in a pungent and unpleasant smell at the site of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com