Dye-Based Polarizers and Polarizers

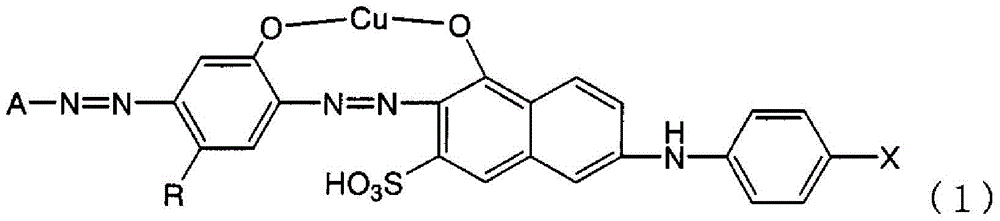

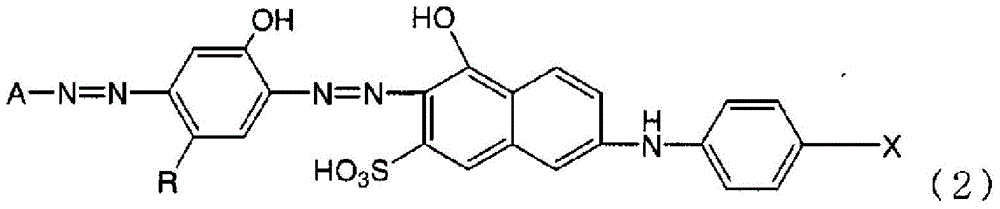

A technology of polarizing elements and polarizers, which is applied in the direction of optical elements, polarizing elements, azo dyes, etc., can solve problems such as difficulties, increased requirements for improvement, and discoloration of polarizers, and achieve good dyeability and good polarizing properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087]

[0088] A polyvinyl alcohol-based resin film (VF series manufactured by Kuraray Co., Ltd.) having a saponification degree of 99% or more and a film thickness of 75 μm was immersed in warm water at 40° C. for 2 minutes to perform swelling treatment. The film after the swelling treatment was salted out in a 20% by weight aqueous solution containing a pigment represented by formula (3) using 25% by weight of Sanuki salt (Sanuki salt), dried at 60°C, and dried The dye powder (HPLC purity 98.2%) was immersed in 45 degreeC aqueous solution containing 0.1 weight% of sodium tripolyphosphate at 0.05 weight%, and adsorption|suction of the dye was performed. The dye-adsorbed membrane was washed with water, and after washing, boric acid treatment was performed for 1 minute with a 40° C. aqueous solution containing 2% by weight of boric acid. The film obtained by the boric acid treatment was stretched 5.0 times, and treated in a 55° C. aqueous solution containing 3.0% by weight o...

Embodiment 2

[0092] In Example 1, 2-methoxyaniline was replaced by 2,5-dimethoxyaniline to prepare a pigment solution having a compound represented by formula (4), and polarized light was obtained by using pigment powder (HPLC purity 98.6%) A polarizing plate and an evaluation sample were produced in the same manner as the other elements. When the polarizing element obtained in Example 2 was dissolved and measured by HPLC, the purity of the dye represented by the formula (4) in the film was 98.8%.

Embodiment 3

[0094] The phenyl J acid used in Example 1 was replaced by methyl phenyl J acid to prepare a pigment solution having a compound represented by formula (5), and a polarizing element was obtained by using pigment powder (HPLC purity 97.8%). Otherwise, a polarizing plate and an evaluation sample were produced in the same manner. When the polarizing element obtained in Example 3 was dissolved and measured by HPLC, the purity of the dye represented by the formula (4) in the film was 97.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com