An in-situ online monitoring method for the stress of reinforced concrete structures

A technology of reinforced concrete and structural stress, which is applied to the measurement of the property force of piezoelectric devices, etc., can solve the problems of stress monitoring, inability to achieve in-situ monitoring, and sensors are easily affected by external factors, and achieves simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

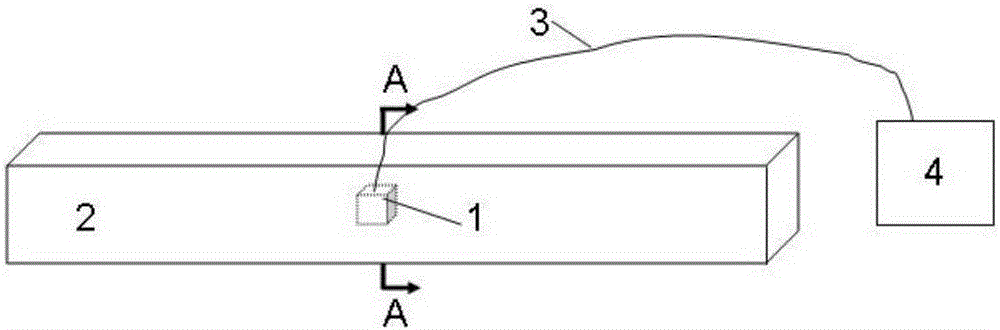

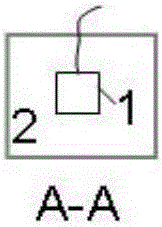

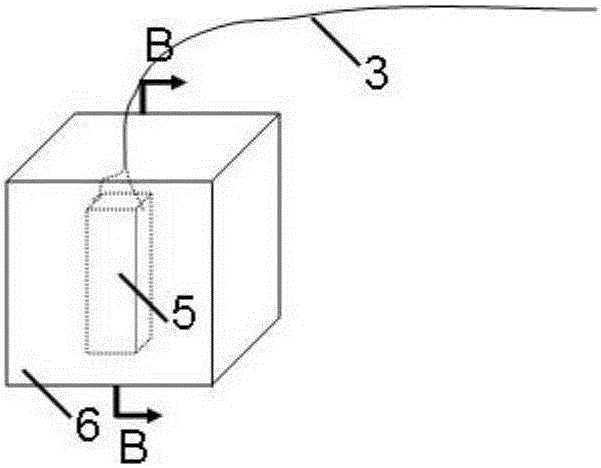

[0056] Using the in-situ monitoring method of the concrete structure stress involved in the present invention, the linear performance of the sensors under the impact load is tested on three reinforced concrete beams with dimensions of 100mm×100mm×1200mm. The structural schematic diagram of the 1-3 type cement-based piezoelectric composite material sensor used in the present invention is shown in Figure 2, wherein, 5 is the 1-3 type cement-based piezoelectric composite material, made of PZT-51 piezoelectric ceramics (Hebei Baoding Hongsheng Acoustics Co., Ltd. equipment factory) prepared by cutting-filling method, and its final size is 10mm×10mm×1.5mm; 6 is polymer / cement packaging material, in which the polymer is AB-grouting resin, and the cement is ordinary Portland cement. The mass ratio of polymer to cement is 1:1. The mass mix ratio of the concrete beam is cement: water: sand: gravel: retarder = 1:0.49:1.65:2.19:0.009. The embedding of sensors in the beam is shown in Figu...

Embodiment 2

[0060] Using the in-situ monitoring method for concrete structure stress involved in the present invention, the concrete beam in Example 1 is tested for piezoelectric performance under impact load and cyclic load. Periodic loads are applied by electric picks, the loading frequencies are 5Hz, 10Hz, 20Hz, 30Hz respectively, and the amplitude of half-sine periodic loads is 10000N. The electric picks are bound together with the structure by belts to ensure loading stability. The piezoelectric performance of cement-based piezoelectric composite sensor in reinforced concrete structure is the key to the application of the sensor in reinforced concrete structure. For the piezoelectric performance, this example is mainly studied through the monitoring results under impact load and cyclic load. In order to study the piezoelectric characteristics of the cement-based piezoelectric composite sensor in the compression zone and tension zone of the reinforced concrete beam, impact loads were ...

Embodiment 3

[0065] Using the in-situ monitoring method for concrete structure stress involved in the present invention, the frequency response test of the concrete beam in Example 1 under different frequency cyclic loads is carried out. The frequency response of the sensor is one of the important properties to measure the dynamic response of the sensor. In this embodiment, during the loading process, the amplitude of the input sinusoidal load is kept unchanged at 10000N, and the frequency of the input load is changed, respectively inputting 5Hz, 10Hz, 20Hz, and 30Hz, and these frequencies are all included in the frequency range that includes the vibration of civil engineering structures (0.1Hz-40Hz) to test the frequency response of the sensor. The voltage waveform generated by the sensor is converted into stress, and the stress-time curve results of some sensors are as follows Figure 10 shown. Depend on Figure 10 It can be seen that under half-sine loads of different frequencies, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com