Hemispherical hollow welding sphere joint for large-span space steel structure support

A steel structure and space-spanning technology, which is applied in the direction of building structure and construction, can solve the problems of the adverse effects of anchor bolts on tensile resistance, high bending requirements of embedded slabs, and inconvenient processing and construction, so as to achieve rigidity and stability Good, good tensile strength, height-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

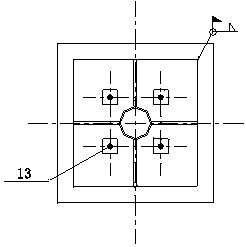

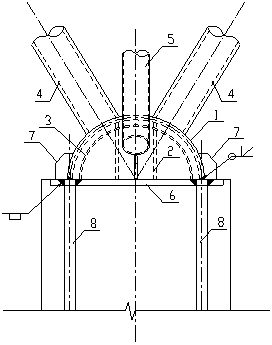

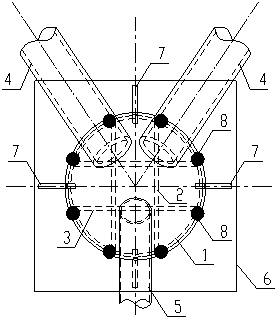

[0019] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, the present invention includes at least four anchor bolts 8, at least two embedded plates 7 are connected on the anchor bolts 8; at least one external stiffening plate is welded on the embedded plate 7; the hemispherical shell 1 are respectively welded to the embedded plate 7 and the external stiffening plate; with the hemispherical shell 1 as a ball joint, at least one main pipe and a branch pipe are welded on the hemispherical shell 1, and on the hemispherical shell 1 A transverse semicircular stiffener and a longitudinal semicircular stiffener are also welded together.

[0020] According to the present invention, the hemispherical shell 1 and the transverse semicircular stiffening plate 2, the hemispherical shell 1 and the longitudinal semicircular stiffening plate 3 are welded by double-sided fillet welds; the hemispherical shell 1 and the pre-em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com