A mining built-in scraper type bucket rear unloading loader

A loader and scraper technology, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. and other problems, to achieve the effect of saving excavation costs, reducing excavation height, and reducing track laying costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

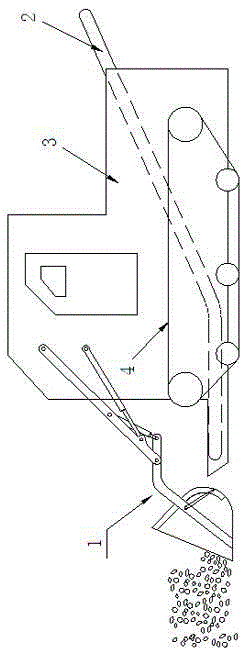

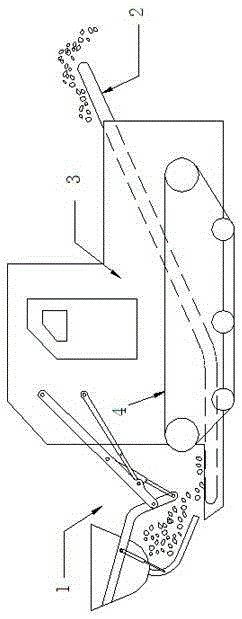

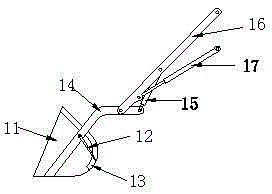

[0011] According to the accompanying drawings, the present invention is a mining built-in scraper type bucket rear unloading loader, which consists of a car body 3 and crawler belts 4, and also includes a bucket mechanism 1 and a built-in scraper machine 2, wherein the bucket mechanism includes Bucket 11, unloading plate 13, unloading plate control cylinder 12, small boom 14, small boom control cylinder 15, big boom 16, big boom control cylinder 17. The bucket 11 is U-shaped, wherein, according to the attached Figure 6 , the front straight section of the bucket 11 is the AB section, the bottom arc section is the BC section, the back straight section is the CD section, and the opening section is the AD section. The unloading plate 13, the unloading plate 13 is half U-shaped, and its bottom is connected with the bottom of the bucket 11 through the hinge point 1, and the unloading plate 13 can rotate around the hinge point 1. One end of the unloading plate control cylinder 12 i...

no. 2 example

[0015] According to the accompanying drawings, the present invention is a mining built-in scraper type bucket rear unloading loader, which consists of a car body 3 and crawler belts 4, and also includes a bucket mechanism 1, a first built-in scraper machine 21, a second built-in The scraper machine 23 (the second built-in scraper machine is obtained by shortening the length of the built-in scraper machine in the first embodiment) and the transfer funnel 22, wherein the bucket mechanism includes a bucket 11, a discharge plate 13, and a discharge plate control Oil cylinder 12, small boom 14, small boom control cylinder 15, big boom 16, big boom control cylinder 17. The bucket 11 is U-shaped, wherein, according to the attached Figure 6 , the front straight section of the bucket is AB section, the bottom arc section is BC section, the back straight section is CD section, the opening section is AD section, the back of the bucket is open type, and the opening on the back of the buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com