Superfine hollow polyester polar fleece shell fabric and production method thereof

A hollow polyester polar fleece and production method technology, applied in the direction of fabric surface trimming, textile material treatment, textile material continuous treatment, etc., can solve the problem that the hollow fiber structure is easily damaged, affecting the thermal performance and moisture absorption performance of the product, Dry and warm effect is not good and other problems, to achieve the desired effect of style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

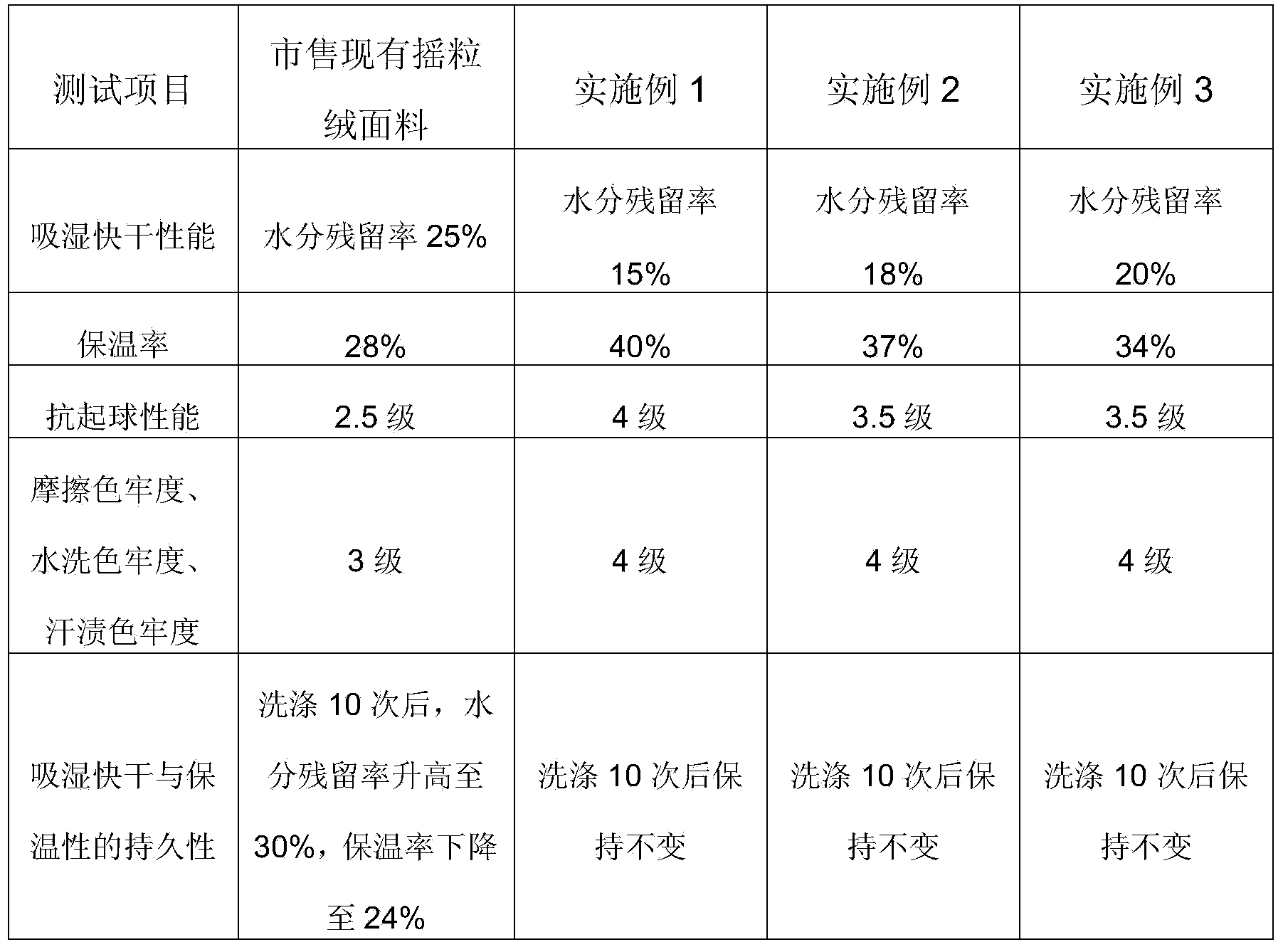

Embodiment 1

[0026] This embodiment provides an ultra-fine hollow polyester polar fleece fabric, which is woven from ultra-fine hollow polyester yarn. The ultra-fine hollow yarn has a hollow structure with a hollowness of 20-30%.

[0027] The production method of the superfine hollow polyester polar fleece fabric of the present embodiment comprises the steps:

[0028] Step 1: Weaving ultra-fine hollow polyester yarn on the machine: choose a large circular machine with a machine number of 16-28N, the coil length is 13.5-18cm, and the weight of the finished fabric is 160-180g / m 2 ;

[0029] Step 2: pre-dyeing treatment: the treatment temperature is 70-90°C, and 0.3-0.6 g / l of pre-treatment agent chiliron and 0.4-0.7 g / l of soda ash are added;

[0030] Step 3: Dyeing: Add dyes and auxiliaries at 60°C, raise the temperature to 120-140°C at a rate of 1-2°C / min and maintain for 30-60 minutes, then cool down to 60-80°C at a rate of 3°C / min , the liquor ratio is 1:12;

[0031] Step 4: Reduction...

Embodiment 2

[0041] This embodiment provides an ultra-fine hollow polyester polar fleece fabric, which is woven from ultra-fine hollow polyester yarn. The ultra-fine hollow yarn has a hollow structure with a hollowness of 20-30%.

[0042] The production method of the superfine hollow polyester polar fleece fabric of the present embodiment comprises the steps:

[0043] Step 1: Weaving ultra-fine hollow polyester yarn on the machine: choose a large circular machine with a machine number of 16-28N, the coil length is 13.5-18cm, and the weight of the finished fabric is 180-200g / m 2 ;

[0044] Step 2: pre-dyeing treatment: the treatment temperature is 70-90°C, and 0.3-0.6 g / l of pre-treatment agent chiliron and 0.4-0.7 g / l of soda ash are added;

[0045] Step 3: Dyeing: Add dyes and auxiliaries at 60°C, raise the temperature to 120-140°C at a rate of 1-2°C / min and maintain for 30-60 minutes, then cool down to 60-80°C at a rate of 3°C / min , the liquor ratio is 1:12;

[0046] Step 4: Reduction...

Embodiment 3

[0056] This embodiment provides an ultra-fine hollow polyester polar fleece fabric, which is woven from ultra-fine hollow polyester yarn. The ultra-fine hollow yarn has a hollow structure with a hollowness of 20-30%.

[0057] The production method of the superfine hollow polyester polar fleece fabric of the present embodiment comprises the steps:

[0058] Step 1: Weaving ultra-fine hollow polyester yarn on the machine: choose a large circular machine with a machine number of 16-28N, the coil length is 13.5-18cm, and the weight of the finished fabric is 200-220g / m 2 ;

[0059] Step 2: pre-dyeing treatment: the treatment temperature is 70-90°C, and 0.3-0.6 g / l of pre-treatment agent chiliron and 0.4-0.7 g / l of soda ash are added;

[0060] Step 3: Dyeing: Add dyes and auxiliaries at 60°C, raise the temperature to 120-140°C at a rate of 1-2°C / min and maintain for 30-60 minutes, then cool down to 60-80°C at a rate of 3°C / min , the liquor ratio is 1:12;

[0061] Step 4: Reduction c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com