Vacuum glass sealing structure and forming method thereof

A vacuum glass and sealing technology, applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problems of mechanical strength deterioration, disappearance, high heating temperature, etc., and achieve high sealing strength and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

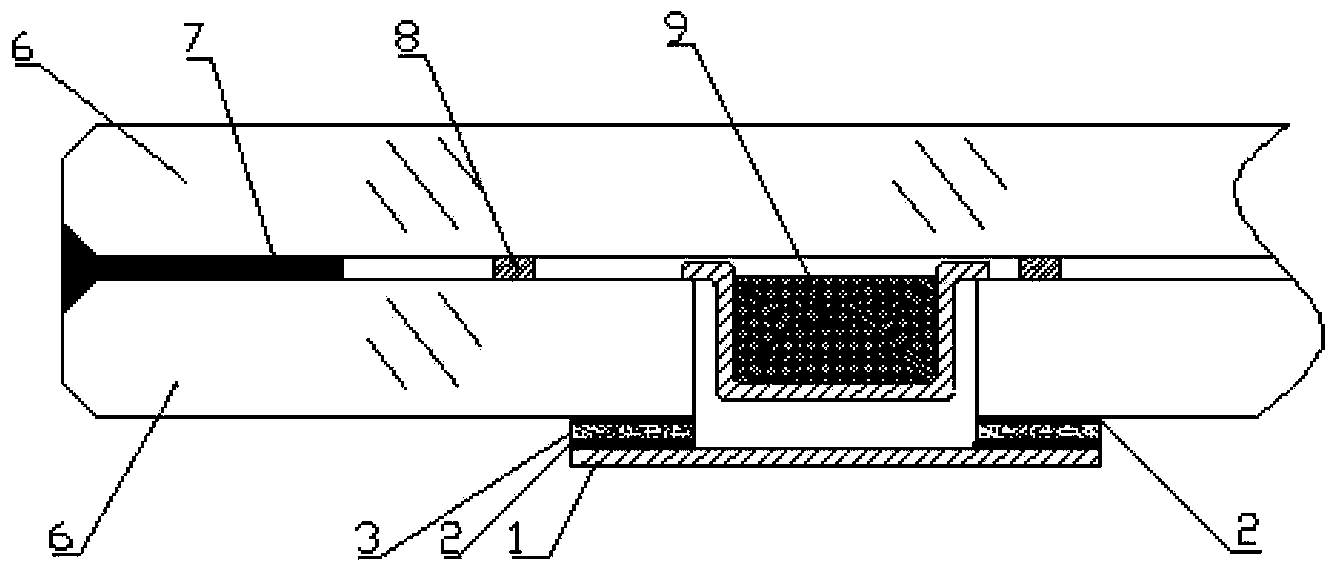

[0018] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

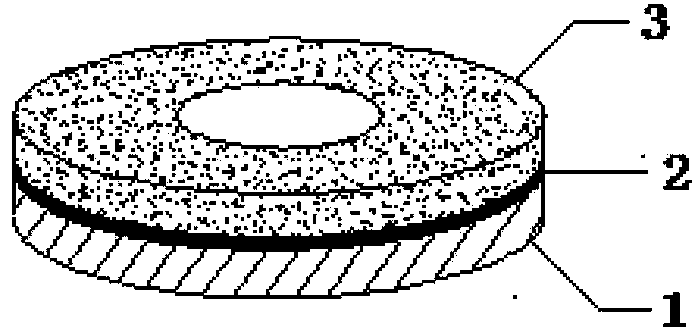

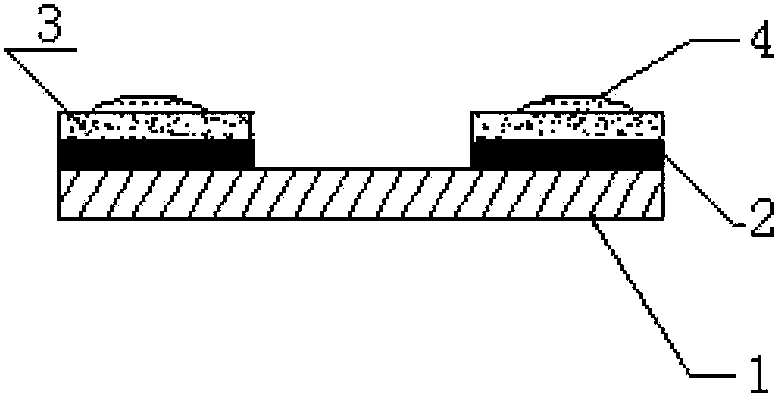

[0019] figure 1 It is a schematic diagram of a vacuum glass sealing sheet according to a preferred embodiment of the present invention, the sealing sheet covers the air suction port 9 on the glass panel 6 and aligns with its center. A solder 3 is arranged between the glass panel 6 and the sealing substrate 1 . In order to realize the sealing of the air extraction port 9 in a low-temperature environment, the solder 3 is a low-melting-point solder capable of melting between 150°C and 350°C.

[0020] exist figure 1 Among them, since the thermal expansion coefficient of the solder 3 after solidification is quite different from that of the glass, in order to ensure the welding strength and sealing performance, the solder 3 is required to have good mechanical properties, its elongation ≥ 20%, and the tensile strength ≥20MPa.

[0021] like figure 1 As...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com