Liquid metal ink-jet printing equipment and printing method

An inkjet printing equipment and liquid metal technology, applied in printing devices, printing, etc., can solve problems such as high environmental pollution, complex manufacturing procedures of integrated circuits or electronic devices, large material and energy consumption, and achieve energy consumption and material inefficiency Effects of low loss, reduced complexity and cost, and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

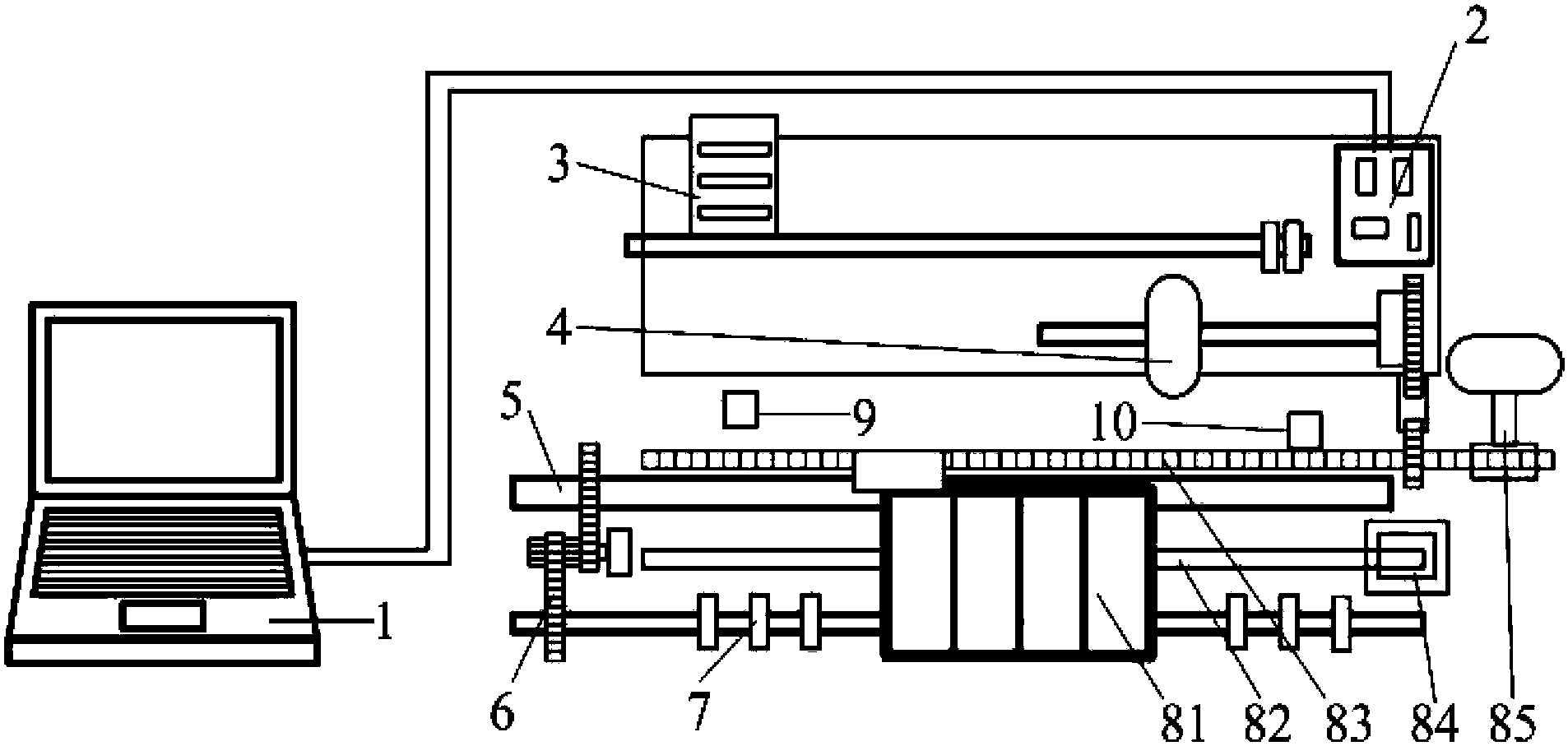

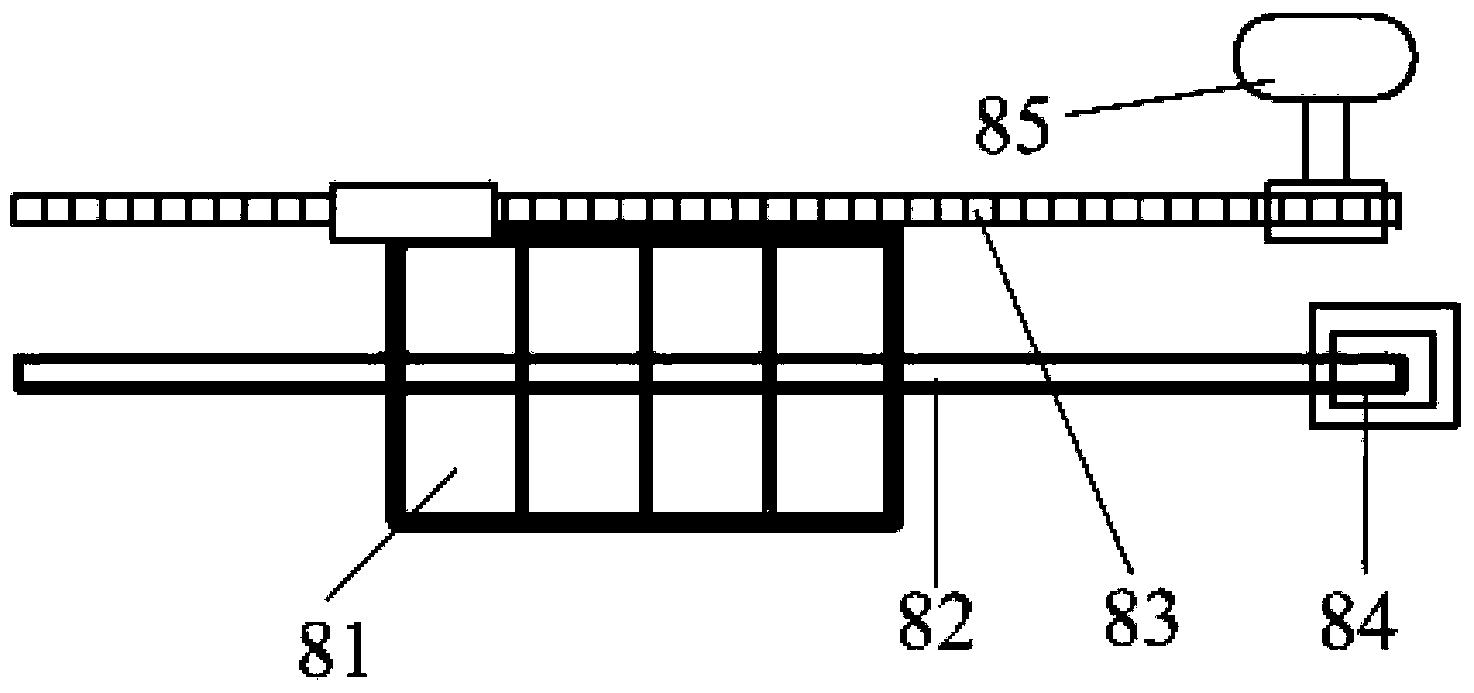

[0050] attached figure 1 It is a structural schematic diagram of the liquid metal micro piezoelectric printer of the present invention. The main structure of the printer includes: a computer 1 with built-in printing control software, a control circuit board 2 built in the liquid metal micro piezoelectric printer, a paper feeder 3, Platen roller 4 , paper feed roller 5 , gear set 6 , paper output roller 7 , carriage mechanism 8 , bottom end paper sensor 9 and carriage initial position sensor 10 . Among them, the control circuit board 2 is used to receive the printing control instruction from the computer 1, and control the paper feeder 3, paper pressing roller 4, paper feeding roller 5, gear set 6, paper output roller 7, initial Position sensor 9 carries out coordinated operation with word car mechanism. The paper feeder 3 and the platen roller 4 are used to guide and flatten the printing substrate. The paper feed roller 5 and the gear set 6 are used to make the paper feeder ...

Embodiment 2

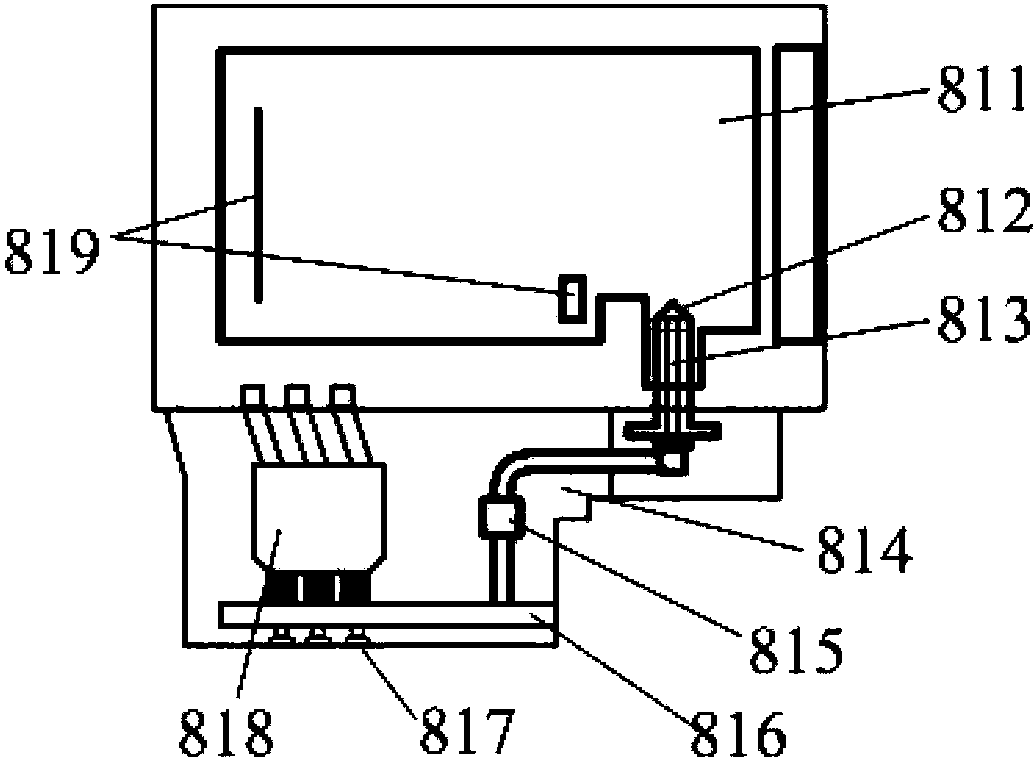

[0059] The only difference between this embodiment and Embodiment 1 is the electric control driving mode. In this embodiment, the injection of the ink at the nozzle is driven by an electromagnetic pump. Since liquid metal is a conductive fluid, it is easy to realize spraying under automatic control by using an electromagnetic pump, and its spraying speed depends on the current on the flow channel. Here, the ejection driving element is the electromagnetic pump 818 , and after it starts running, the liquid metal ink will be pushed to the nozzle by the electromagnetic force generated by the electromagnetic pump and ejected onto the printing substrate. Component 818 is an inkjet head drive device that adopts the working principle of metal liquid electromagnetic drive. When the control circuit board 2 sends a print command signal, the electromagnetic pump component 818 exerts a Lorentz electromagnetic force on its internal fluid, and then the ink stored in the ink chamber 814 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com