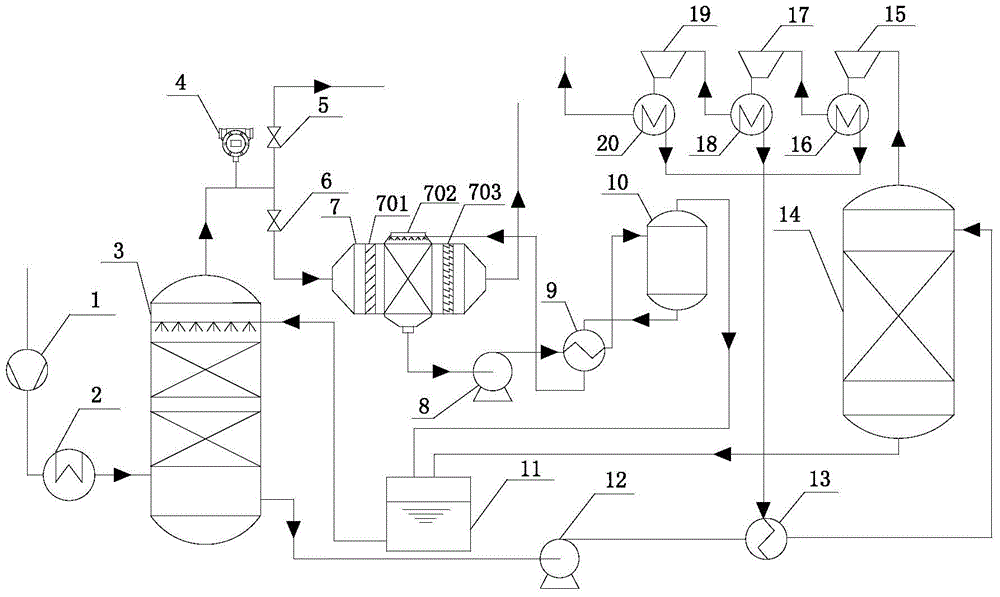

A flue gas carbon dioxide capture system and capture method

A carbon dioxide and carbon capture technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve problems such as high investment and operation costs, high MEA price, high regeneration temperature, avoid losses and re-pollution, and solve high Volatilization loss, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In Embodiment 1 of the present invention, a flue gas carbon dioxide capture system includes:

[0045] (1) A carbon dioxide absorption tower, the bottom of which is provided with the original flue gas inlet and the carbon capture rich liquid outlet, and the top is provided with a flue gas outlet, and the inside of the carbon dioxide absorption tower is provided with a top-down spray ammonia absorbent The spray layer, the position of the spray layer is higher than the position of the original flue gas inlet. The invention uses ammonia water as an absorbent to countercurrently react with the flue gas fed into the carbon dioxide absorption tower to capture the carbon dioxide in the flue gas. Among them, the position of the spray layer used for spraying the ammonia water absorbent should be higher than the position of the original flue gas inlet, so that the countercurrent between the flue gas and the absorbent can be formed. At the same time, the position of the flue gas o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com