Housing of mobile terminal, and manufacturing method for same

A mobile terminal and manufacturing method technology, applied to metal casings and other directions, can solve the problems of long processing and production cycle, difficult standardization, low yield, etc., and achieve the effect of improving processing efficiency and production yield, and reducing destructive effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

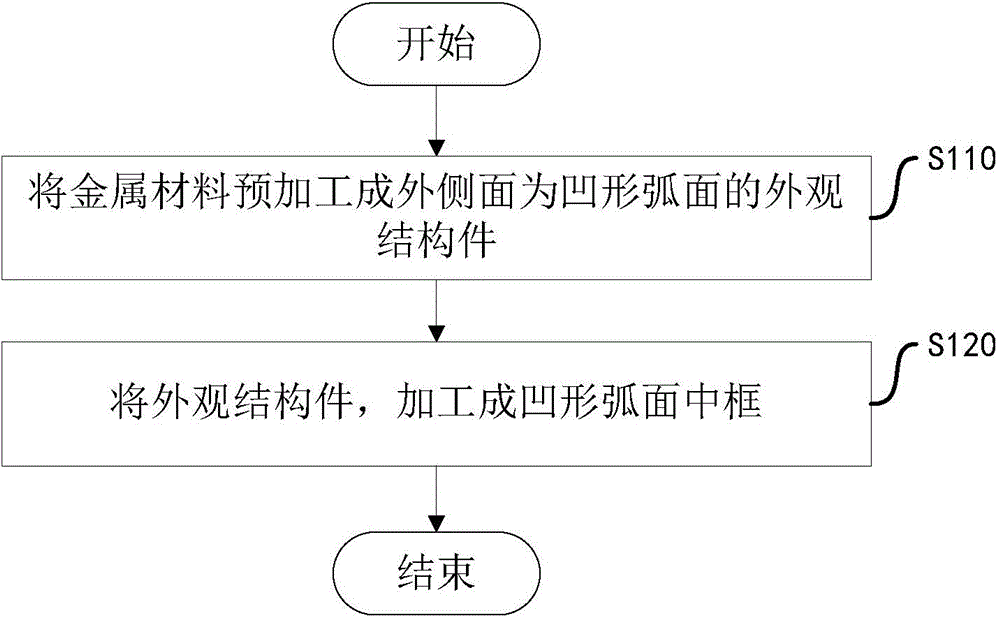

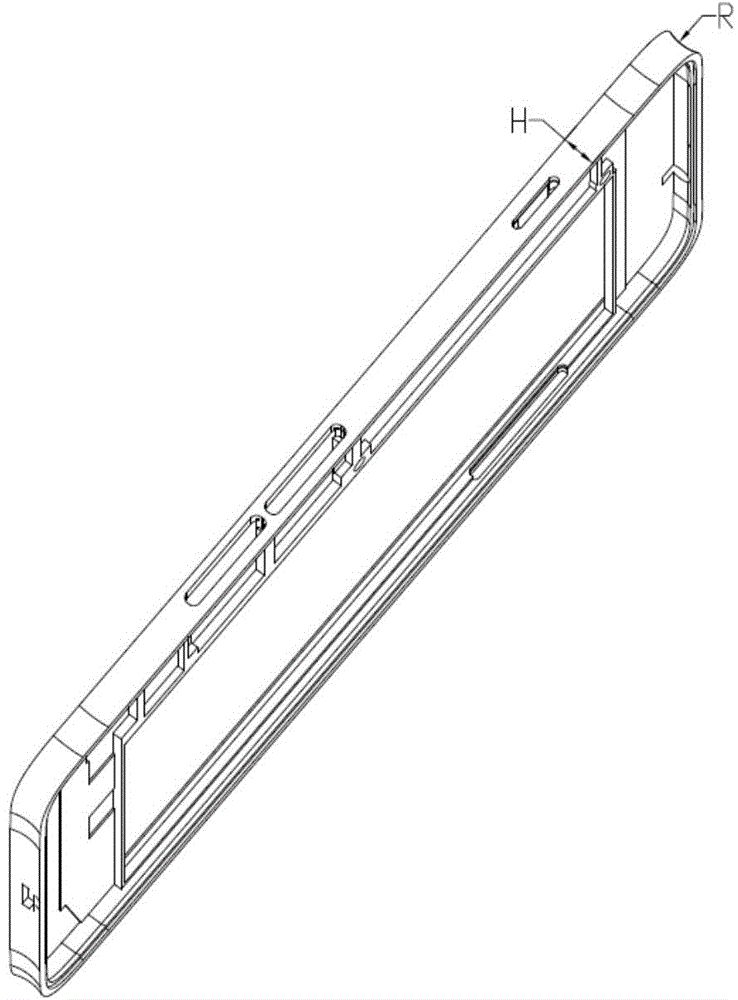

[0023] The invention provides a casing of a mobile terminal and a manufacturing method thereof. The main idea of the present invention is to adopt a concave curved middle frame in the casing of the mobile terminal. Furthermore, the present invention adopts CNC machining to shape the concave arc surface middle frame, avoids manual jig clamping, and grinds and polishes the arc surface, effectively improving the processing efficiency and production yield of the mobile terminal middle frame; and, the present invention adopts concave The arc-shaped middle frame can reduce the destructive effect of external impact on the built-in parts of the mobile terminal, meet the mechanical performance requirements of the mobile terminal shell, and improve the user's comfort, especially in the ultra-thin mobile terminal. higher.

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com