Brushless DC (Direct current) motor driver

A motor driver, brushed DC motor technology, applied in the direction of single motor speed/torque control, electrical components, emergency protection circuit devices, etc. And the effect of simple after-sales, high precision and simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described by way of embodiment now in conjunction with accompanying drawing.

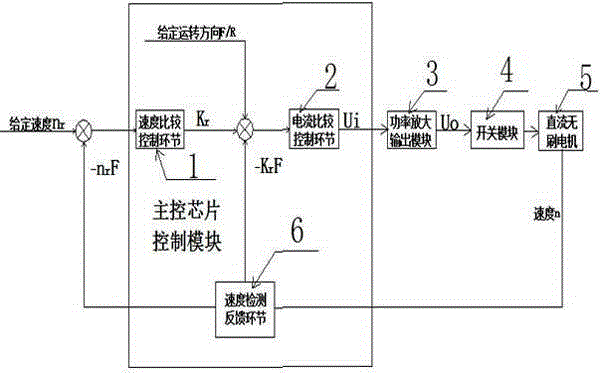

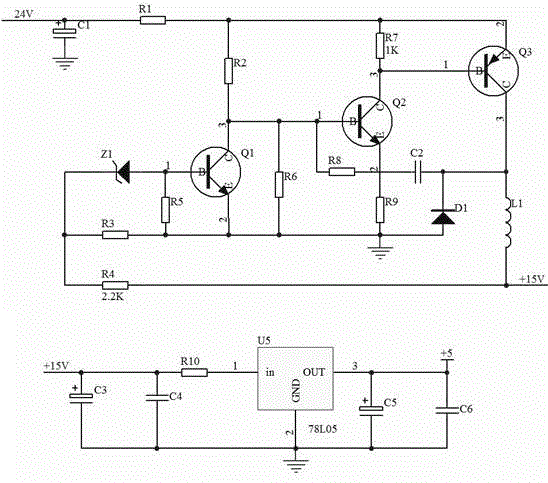

[0019] 1. The functional block diagram of the driver of the present invention is as figure 1 As shown, the power conversion control module, the main control chip control module, the switch module and the power amplification output module of the control system of the driver in this embodiment, wherein the main control chip control module includes three parts: the speed comparison control link, the current comparison control link And speed detection feedback control link.

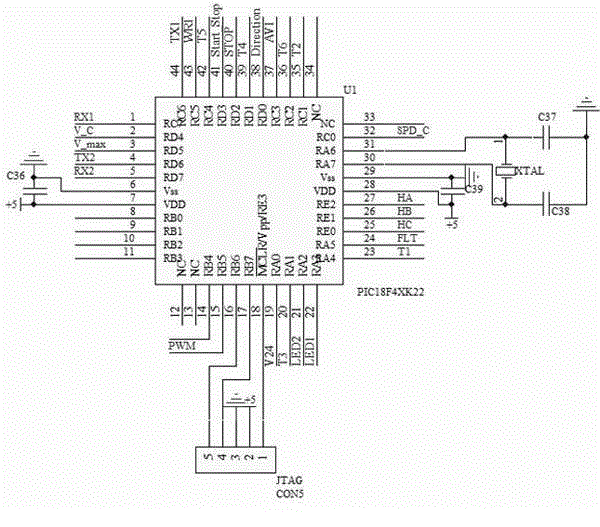

[0020] 2. The main control component is the SOPC programming system on chip. The SOPC-based SOC solution is used as the main control center through the on-chip programmable logic system, and the brushless DC motor is driven to rotate and adjust the speed through the SOPC system execution control mode.

[0021] 3. The drive process of the drive to the motor adopts a closed-loop speed reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com