Low-temperature catalysis type infrared gas heater and catalyst preparation process thereof

A low-temperature catalysis and heater technology, applied in physical/chemical process catalysts, lighting and heating equipment, metal/metal oxide/metal hydroxide catalysts, etc. High hydrocarbon UHC emissions and other issues, to achieve the effect of avoiding strong airflow noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

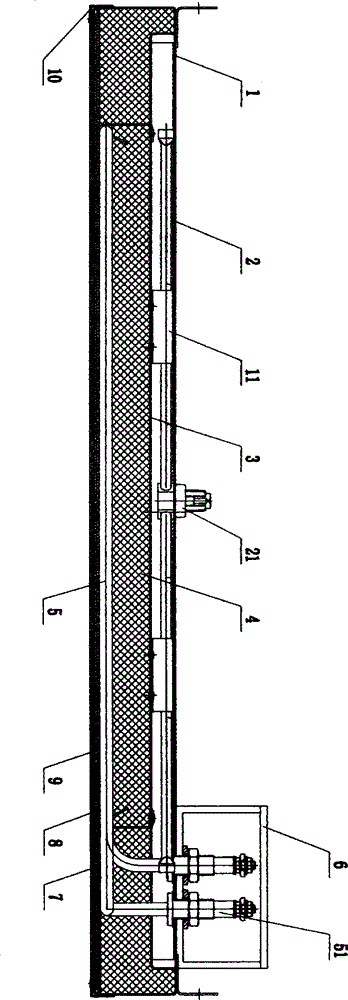

[0031] The present invention will be further described below in conjunction with accompanying drawing:

[0032] Such as figure 1 As shown, the technical scheme adopted by the present invention is as follows: a low-temperature catalytic gas infrared heater, including a housing 1, a gas conduit 2, a gas homogenization assembly, a dry preheating electric heating tube 5 and an active aluminum catalyst layer 8, wherein , the interior of the above-mentioned housing 1 is a cavity structure; the above-mentioned gas conduit 2 is arranged in the cavity structure of the casing 1; the above-mentioned gas homogenization assembly is arranged at the lower part of the gas conduit 2, so as to homogenize the gas released by the gas conduit 2; The above-mentioned dry preheating electric heating tube 5 is arranged in the gas homogenization assembly, so as to preheat the catalyst layer 8 and activate the catalyst on the catalyst layer 8; the above-mentioned active aluminum catalyst layer 8 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com