Construction method and cylinder fixing device for pouring concrete to obtain cylinders by aid of paper forms

A construction method and a technology of fixing devices, which are applied in the fields of formwork/formwork/work frame, processing of building materials, preparation of building components on site, etc., can solve the problem that the concrete cylinder cannot reach the fair-faced concrete and the bottom of the cylinder is prone to grout leakage , Poor look and feel of cylinders, etc., to ensure the effect of fair-faced concrete, good look and feel, and good finished product effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention will be further described:

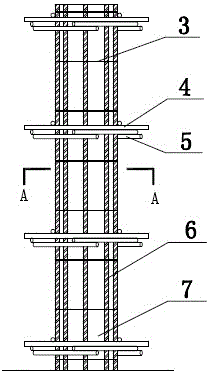

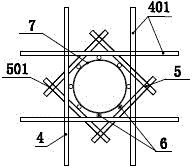

[0036] The equipment involved in the construction process of the present invention includes a paper mold adjusting positioner and a cylinder fixing device.

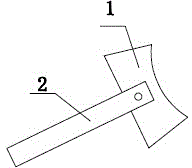

[0037] Such as figure 1 As shown, there are 2-4 paper mold adjusting seats, and the present invention has two, which are respectively arranged in the north-south orientation and east-west orientation, and each paper mold adjusting seat includes a fixedly connected fan-shaped adjusting piece 1 And operating handle 2, described sector-shaped adjusting sheet 1 inner arc corresponds to the outer arc of paper mold, and its inner arc length is 30-50cm, preferably 40mm, operating handle 2 is a square column, operating handle 2 One end is provided with a groove matching the thickness of the fan-shaped adjusting piece 1, the fan-shaped adjusting piece 1 is inserted into the groove, and then fixed by screws. When operating, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com