A decompression plate with a quick disassembly structure

A decompression board and fast technology, applied in the direction of roads, special pavements, dams, etc., can solve the problems of affecting the construction rhythm, long installation and dismantling time, etc., and achieve fast installation and dismantling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

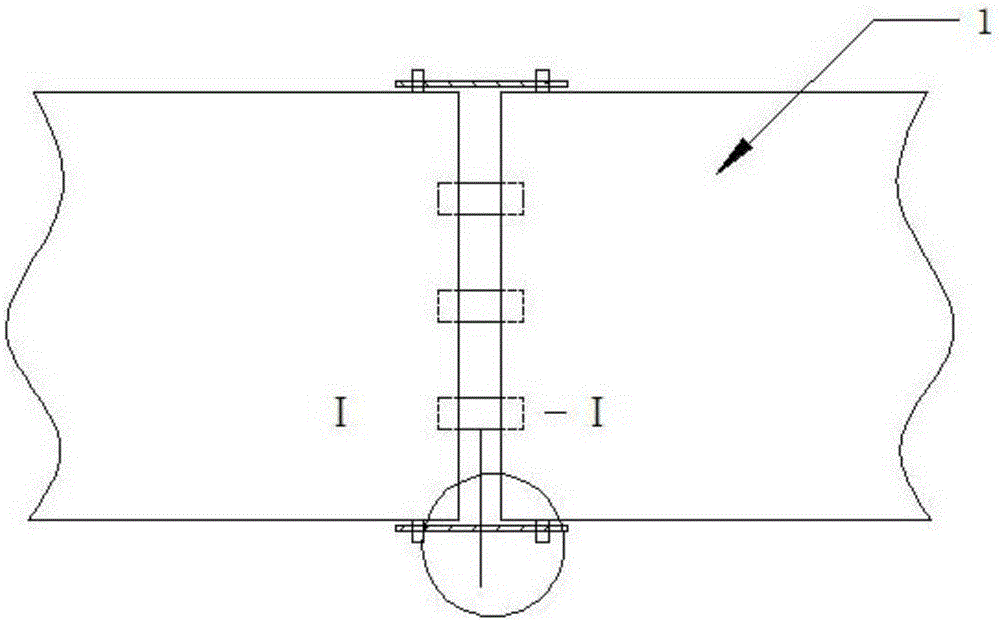

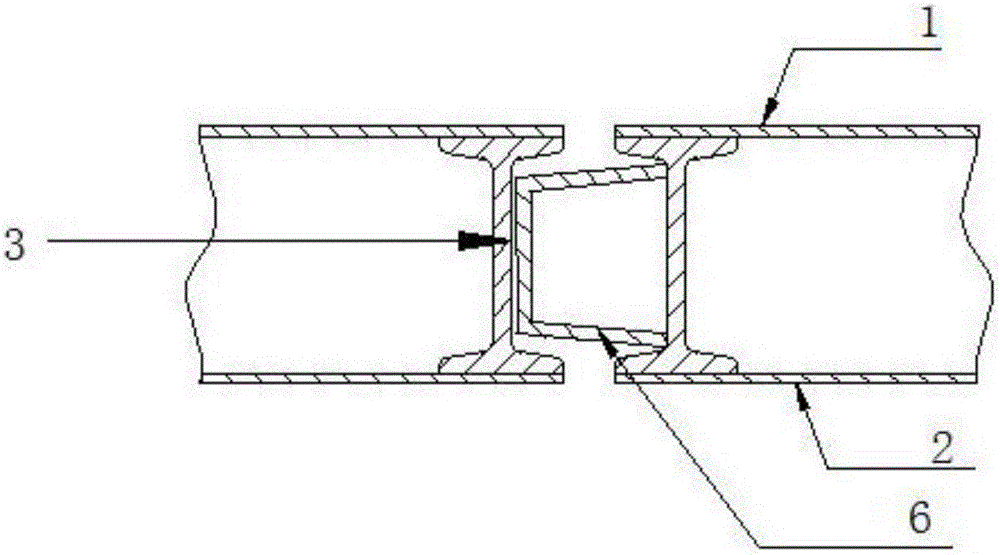

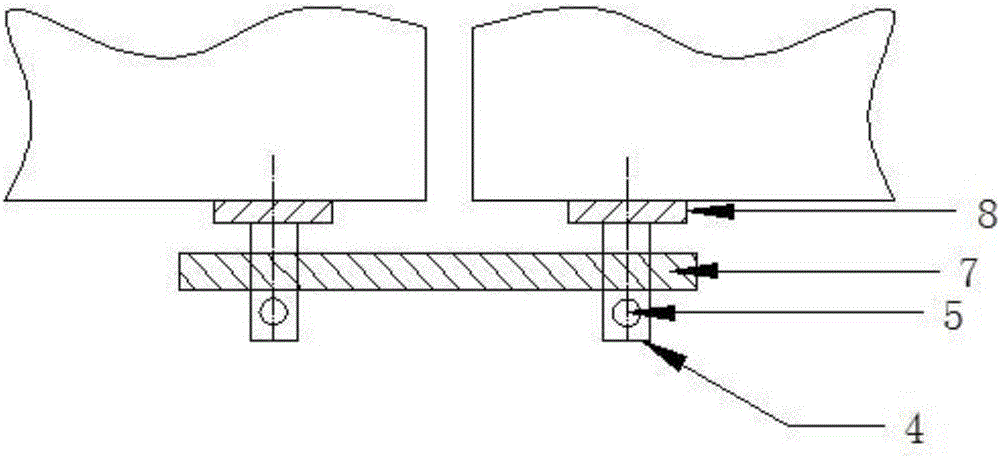

[0030] The panel 1 of the bridge deck has a length and width of 348.8cm×400cm, and the waist height of the I-steel longitudinal rib 11 and the I-steel beam 9 is 180mm; The spacing between the other limiting shafts is 300mm, and the diameters of the above two limiting shafts are 40mm; the length of the bar hole of the limiting ring 7 is 380mm, and the width is 45mm. After the front bridge plate is connected to the rear bridge plate, the gap between the two is 40mm. The panel 1 and the bottom plate 2 are steel plates with a thickness of 10 mm and a thickness of 8 mm respectively; the thickness of the steel plate beam 10 and the steel plate longitudinal rib are both 8 mm; 20mm; the diameter of the pin hole 5 is 16mm. Both end faces of the box-shaped card slot 6 are welded with closed steel plates (to increase mechanical strength). see Figure 5-Figure 8 In the rectangular frame welded by four I-beams, there is also an I-beam welded along the center line parallel to the width d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com