Carboxymethyl-chitosan-starch-polyving-alcohol blending thin film

A carboxymethyl chitosan and polyvinyl alcohol technology, applied in the field of carboxymethyl chitosan-starch-polyvinyl alcohol blend film, can solve the problems of poor film mechanical properties, high brittleness, and unsuitability for acidic environments , to achieve the effects of low production cost, improved quality, and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

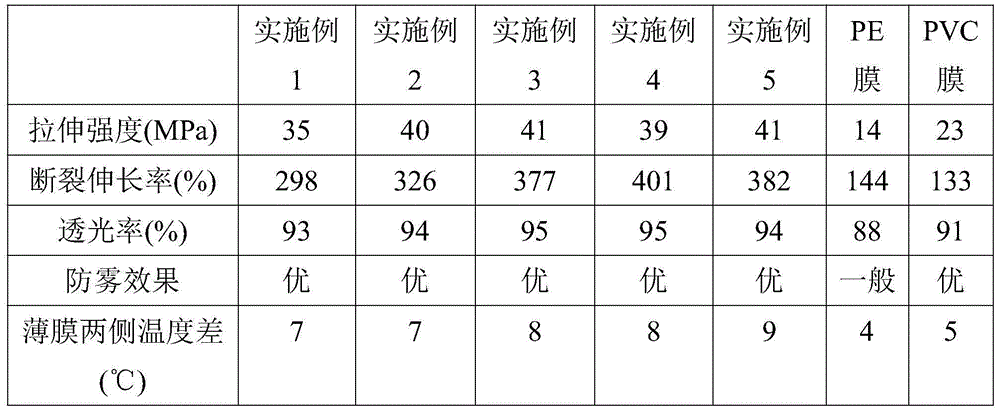

Examples

Embodiment 1

[0018] 50 parts of carboxymethyl chitosan, 15 parts of starch, 15 parts of polyvinyl alcohol, 5 parts of artemisia gum, 2 parts of hydroxypropyl cellulose, 3 parts of nano silicon dioxide, 5 parts of zinc stearate, oxidized polyethylene 4 parts of wax, 2 parts of ethyl silicone oil, 4 parts of glutaraldehyde, 150 parts of distilled water.

Embodiment 2

[0020] 52 parts of carboxymethyl chitosan, 19 parts of starch, 19 parts of polyvinyl alcohol, 6 parts of artemisia gum, 4 parts of hydroxypropyl cellulose, 4 parts of nano silicon dioxide, 6 parts of zinc stearate, oxidized polyethylene 5 parts of wax, 3 parts of ethyl silicone oil, 6 parts of glutaraldehyde, 160 parts of distilled water.

Embodiment 3

[0022] 55 parts of carboxymethyl chitosan, 23 parts of starch, 23 parts of polyvinyl alcohol, 7 parts of artemisia gum, 5 parts of hydroxypropyl cellulose, 4 parts of nano silicon dioxide, 8 parts of zinc stearate, oxidized polyethylene 6 parts of wax, 5 parts of ethyl silicone oil, 7 parts of glutaraldehyde, 170 parts of distilled water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com