An isothermal fixed bed reactor with catalyst installed between heat exchange tubes

A fixed-bed reactor and catalyst technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as small size and catalyst deactivation, and achieve the effects of not easy side reactions and large loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

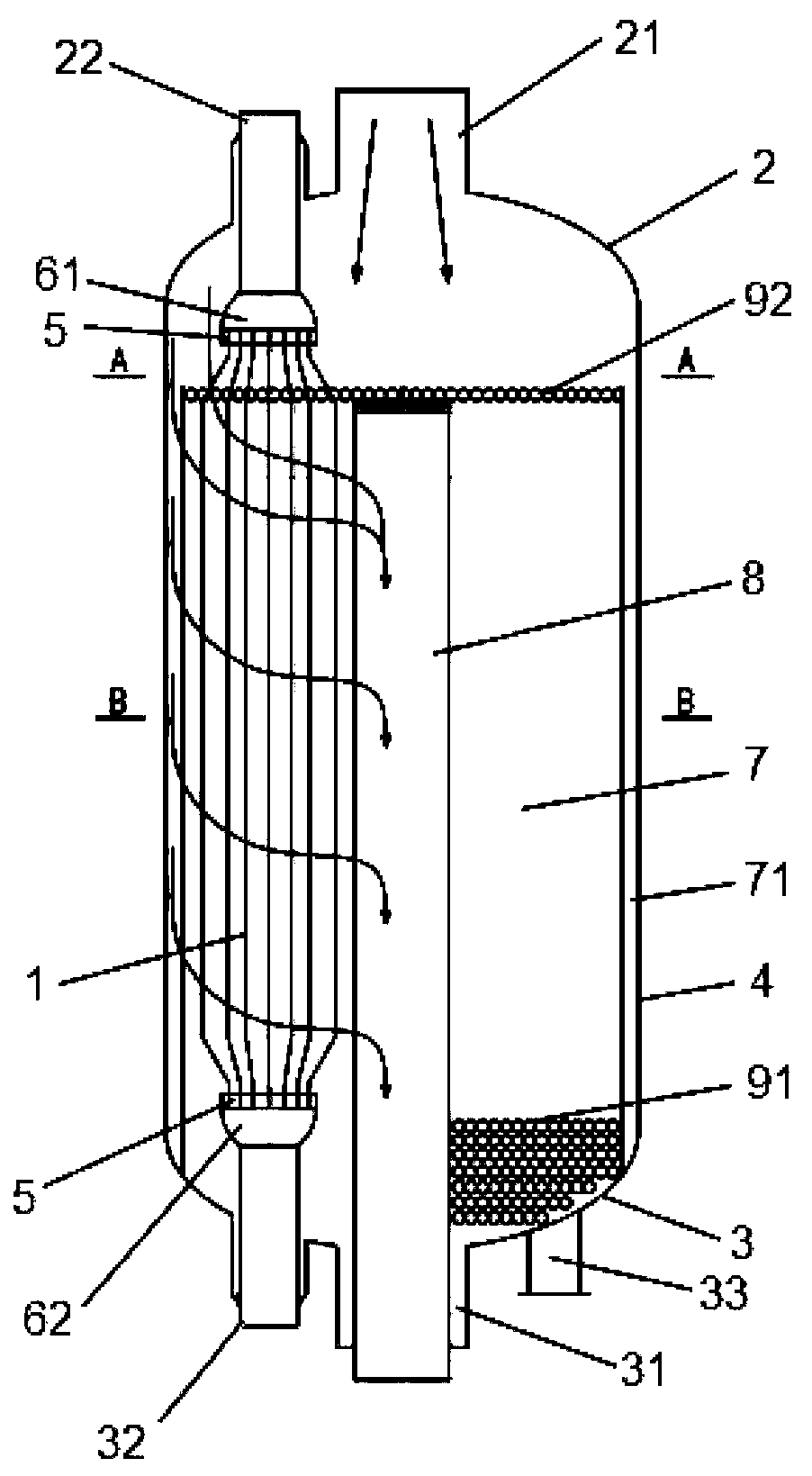

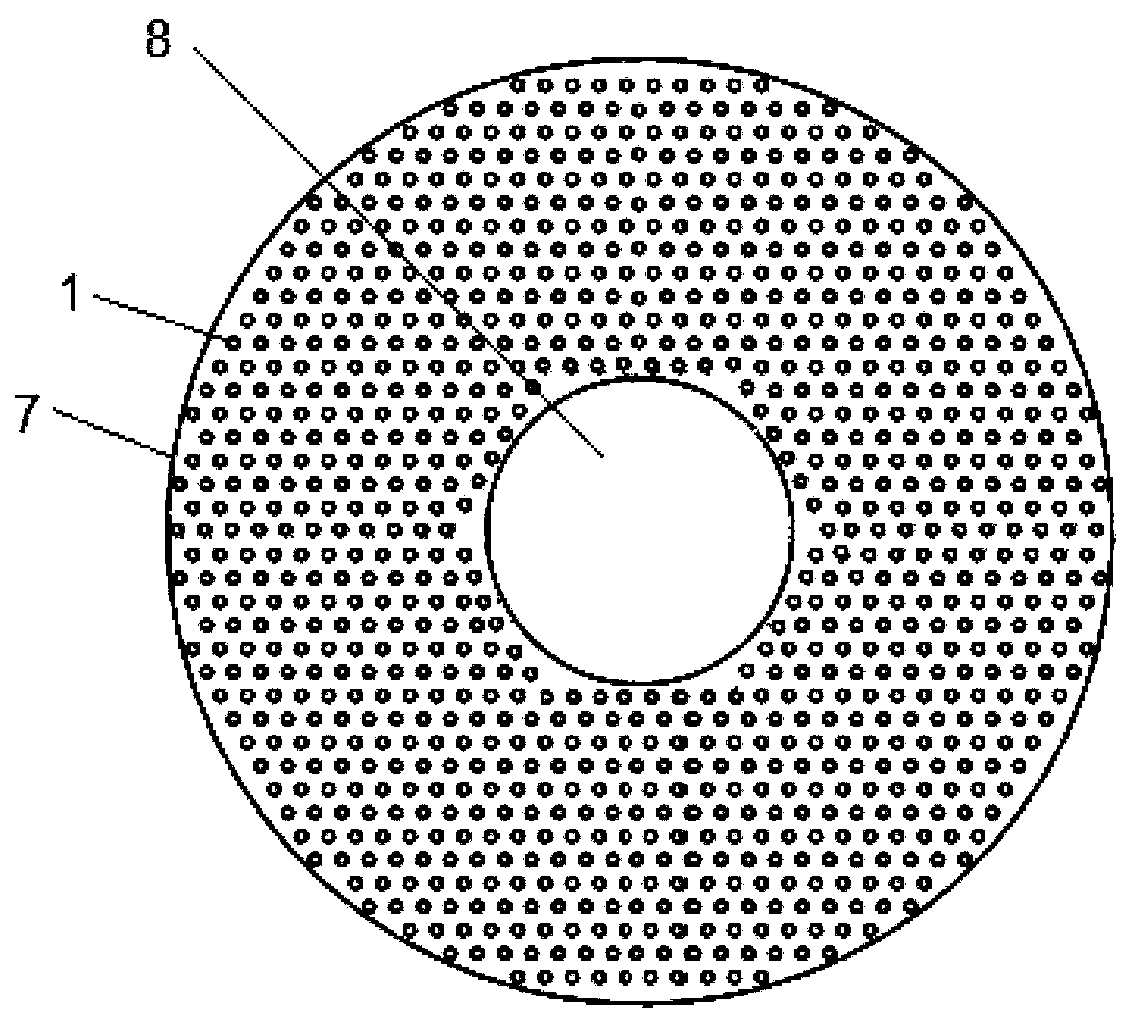

[0051] refer to figure 1 , 2 and 3, an isothermal fixed-bed reactor in which catalyst is installed between heat exchange tubes, is an axial radial reactor, including a pressure-bearing shell, a heat-exchange tube 1 installed in the pressure-bearing shell, and a catalyst cylinder.

[0052] The pressure shell includes an upper head 2, a lower head 3, and a cylinder 4; the upper head 2 is welded to the top of the cylinder 4, and the upper head 2 is provided with a gas inlet 21 and a heat exchange medium outlet 22; The lower head 3 is welded to the bottom of the cylinder body 4 , and the lower head 3 is provided with a gas outlet 31 , a heat exchange medium inlet 32 and a catalyst discharge port 33 .

[0053] The two ends of the heat exchange tube 1 are closed and welded to the tube plate 5 respectively, and communicate with the upper tube box 61 and the lower tube box 62 respectively, the upper tube box 61 is connected with the heat exchange medium outlet 22, and the lower tub...

Embodiment 2

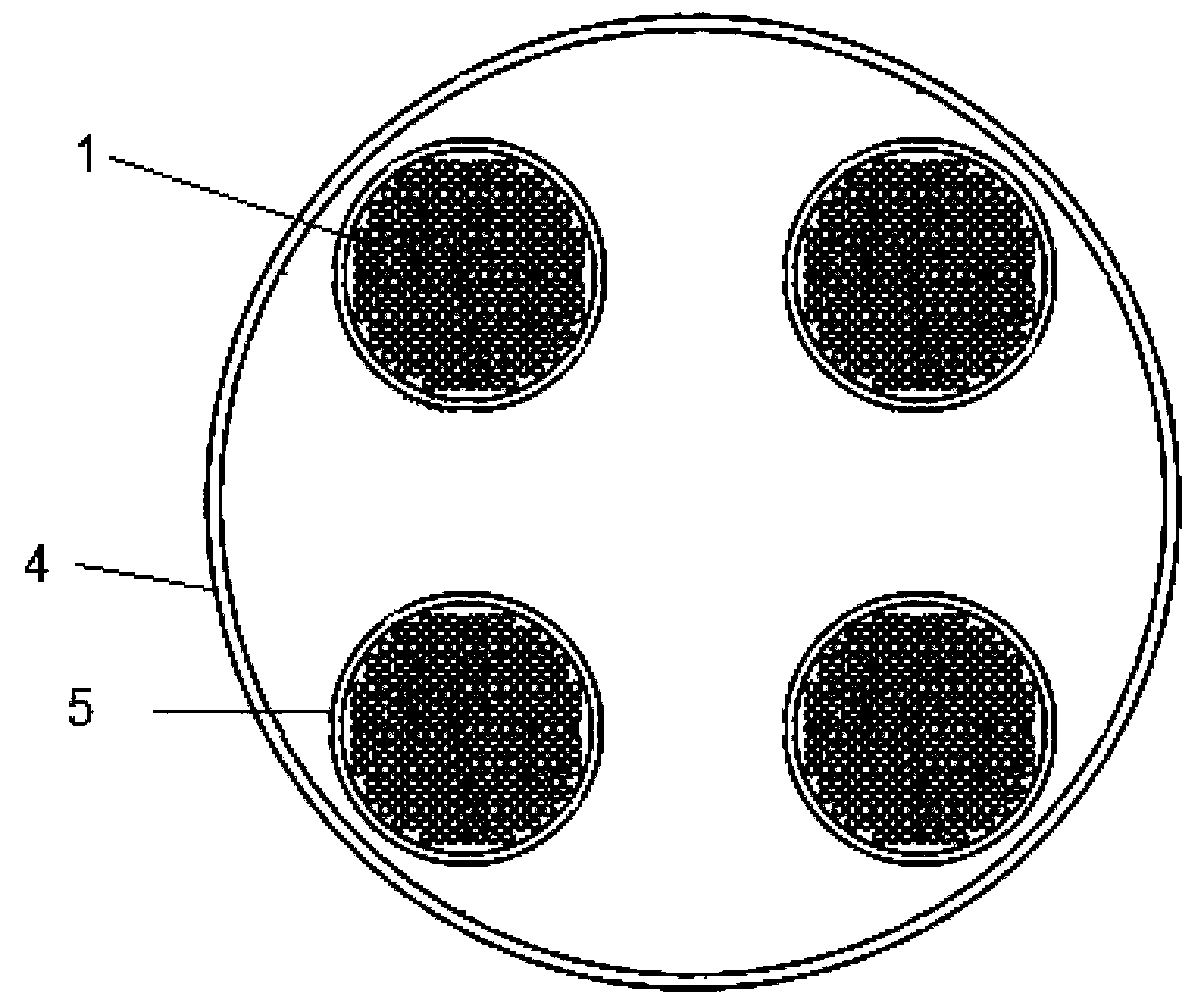

[0059] refer to Figure 4 , an isothermal fixed-bed reactor in which catalyst is installed between heat exchange tubes is an axial reactor comprising a pressure-bearing shell, a heat-exchange tube 1 installed in the pressure-bearing shell and a catalyst cylinder.

[0060] The pressure shell includes an upper head 2, a lower head 3, and a cylinder 4; the upper head 2 is welded to the top of the cylinder 4, and the upper head 2 is provided with a gas inlet 21 and a heat exchange medium outlet 22; The lower head 3 is welded to the bottom of the cylinder body 4 , and the lower head 3 is provided with a gas outlet 31 , a heat exchange medium inlet 32 and a catalyst discharge port 33 .

[0061] The two ends of the heat exchange tube 1 are closed and welded to the tube plate 5 respectively, and communicate with the upper tube box 61 and the lower tube box 62 respectively, the upper tube box 61 is connected with the heat exchange medium outlet 22, and the lower tube box 62 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com