Canned edible bean and preparation method thereof

A technology of canning and sealing, which is applied in the field of food processing and preparation, can solve the problems of red bean flavor weakening, red bean taste deterioration, flavor deterioration, etc., to achieve good appearance and shape, not easy to rot and deterioration, and complete nutritional components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

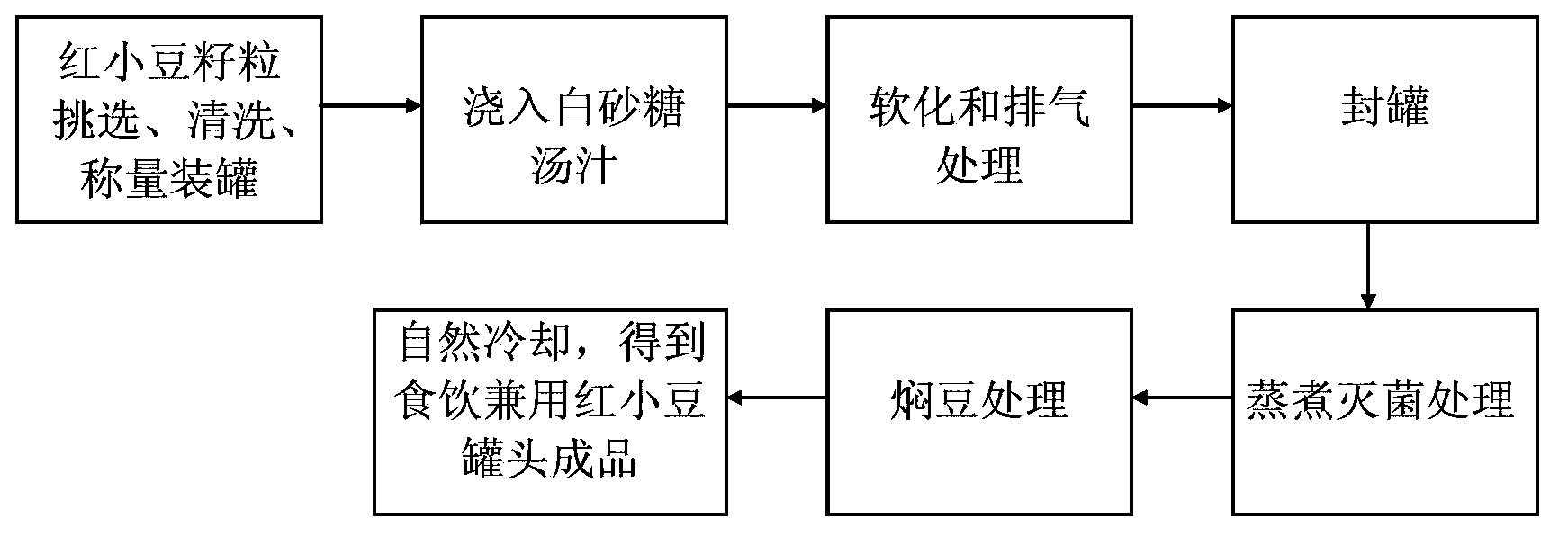

Method used

Image

Examples

Embodiment 1

[0043] 1. Canning

[0044] Put the cleaned red beans into a can, then add white granulated sugar soup, mix evenly, wherein the weight ratio of red bean to white sugar soup is 1:20; the mass percentage of sugar in white sugar soup The concentration is 7.5%, and the temperature of the white sugar soup is 90°C; the total volume of the added red bean and white sugar soup accounts for 99% of the volume of the can.

[0045] 2. Exhaust and softening treatment

[0046] Put the cans containing the red bean and white sugar soup in a water bath for exhausting and softening treatment. During the exhausting and softening process, keep the temperature of the water bath at 95°C, remove the air in the cans, and soften at the same time The red bean seed coat is exhausted and softened after 12 minutes, and the can box is sealed quickly.

[0047] 3. Cooking treatment

[0048] The sealed cans were placed in an autoclave, heated, and subjected to cooking treatment, wherein the temperature of th...

Embodiment 2

[0052] 1. Canning treatment

[0053] The red bean after cleaning is packed in can, then adds soft white sugar soup, mixes evenly, wherein the weight ratio of red bean and soft white sugar soup is 1:7; The quality of soft white sugar in soft white sugar soup The percentage concentration is 5%, and the temperature of the soft white sugar soup is 98°C; the total volume of the added red bean and soft white sugar soup accounts for 90% of the volume of the can.

[0054] 2. Exhaust and softening treatment

[0055] Put the cans containing the red bean and soft white sugar soup in a water bath for exhaust and softening treatment, wherein the temperature of the water bath is kept at 100°C during the exhaust and softening process, and the air in the cans is removed and softened at the same time The red bean seed coat is exhausted and softened for 7 minutes, and the can box is quickly sealed.

[0056] 3. Cooking treatment

[0057] Put the sealed can in an autoclave, heat it, and carry ...

Embodiment 3

[0061] 1. Canning treatment

[0062] The red bean after cleaning is packed in can, then adds brown sugar soup, mixes evenly, wherein the weight ratio of the weight of red bean and brown sugar soup is 1:25; The mass percentage concentration of brown sugar in brown sugar soup is 10 %, the temperature of the brown sugar soup is 95°C; the total volume of the added red beans and brown sugar soup accounts for 95% of the volume of the can.

[0063] 2. Exhaust and softening treatment

[0064] Put the cans containing red bean and brown sugar soup in a water bath for exhausting and softening treatment. During the exhausting and softening process, keep the temperature of the water bath at 97°C to remove the air in the cans and soften the red beans at the same time. The adzuki bean seed coat is exhausted and softened after 12 minutes, and the can box is sealed quickly.

[0065] 3. Cooking treatment

[0066] Put the sealed can in an autoclave, heat it, and carry out cooking treatment, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com