Medium-frequency heating bar and structure thereof

A heating rod and intermediate frequency technology, applied in the direction of induction heating, induction heating control, etc., can solve the problems of poor insulation and sealing performance, high energy consumption of heating rods, and low efficiency, and achieve good insulation and sealing performance, convenient control and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

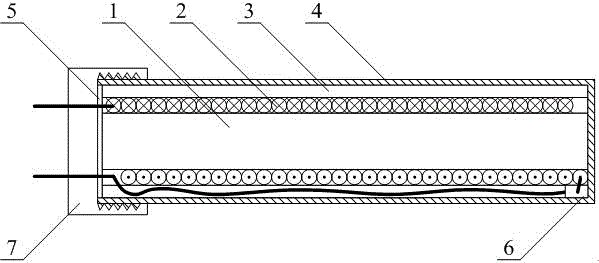

[0015] Such as figure 1 As shown, the intermediate frequency heating rod is composed of a magnetic core rod (1), a copper coil (2), an insulating layer (3), a ferromagnetic tube (4), a magnetic ring (5), a PTC temperature sensitive resistor (6) and a sealing end Part (7) is composed.

[0016] The magnetic core rod (1) is located on the central axis of the ferromagnetic tube (4), and the top of the magnetic core rod (1) is closed by a magnetic ring (5), and the outer diameter of the magnetic ring (5) is the same as the inner diameter of the ferromagnetic tube (4). Similarly, the copper coil (2) is tightly wound on the magnetic core rod (1), and the copper coil (2) is connected to an external intermediate frequency power supply. The copper coil (2) is mainly used to generate an intermediate frequency alternating magnetic field, and the magnetic force line forms a closed loop through the magnetic core rod (1), the magnetic ring (5) and the ferromagnetic tube (4); the magnetic ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com