Electric heating board manufactured by nesting heating elements in foamed aluminum

A technology of heating element and foamed aluminum plate, which is applied in the field of electrothermal conversion, can solve problems such as difficulty in judging the quality of various products, warping and deformation of the plate surface, and difficulty in recycling, so as to eliminate electromagnetic wave hazards, improve cost performance, and heat good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

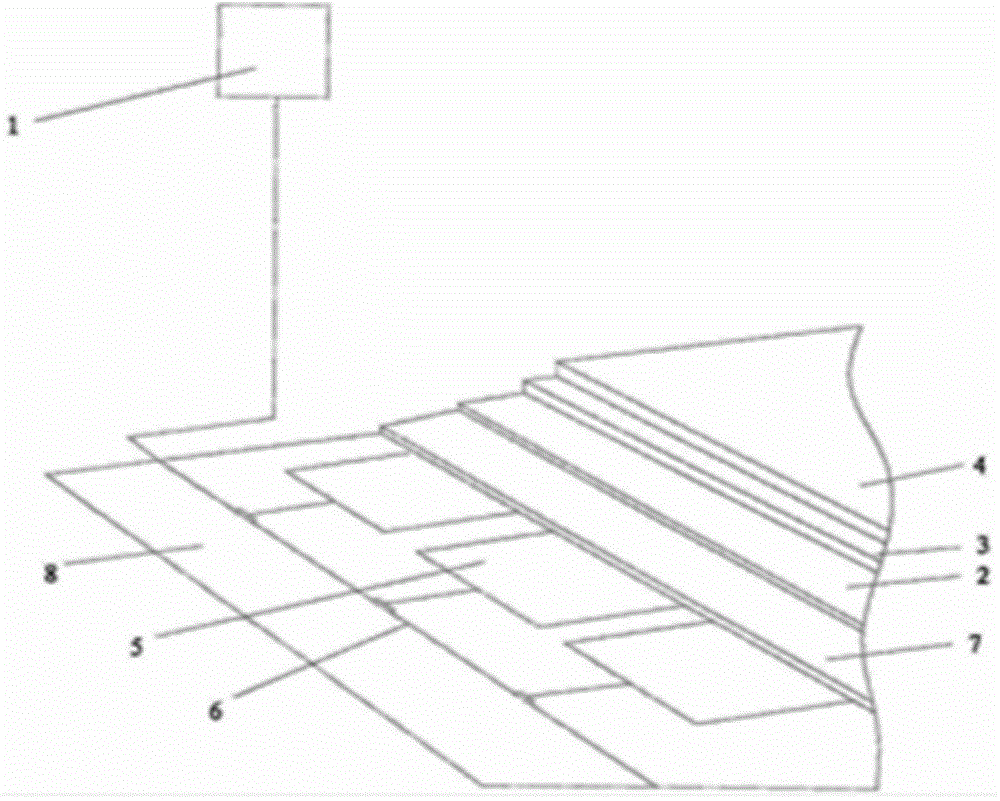

[0043] In this patent background analysis and specification attached Figure 1-4 The 4 disclosed patents on the method of making electric heating panels or floor heating, compared with the production of electric heating panels or floor heating in this patent, except for the heating elements and their temperature control systems, the rest of the laying, bonding, assembling, pressing The multiple and multi-layered wrapping materials are all replaced by a two-layer foamed aluminum plate with different upper and lower functions, which can achieve the following common technical effects: First, the production material is reduced from multiple to one, and from multi-layer sandwiches to The upper and lower layers are sandwiched, and the production method and process are greatly simplified; the second is light weight, foamed aluminum is lighter than any material selected in the 4 patents, and the construction and installation are very convenient; the third is the only one that can use m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com