Damper special for loudspeaker

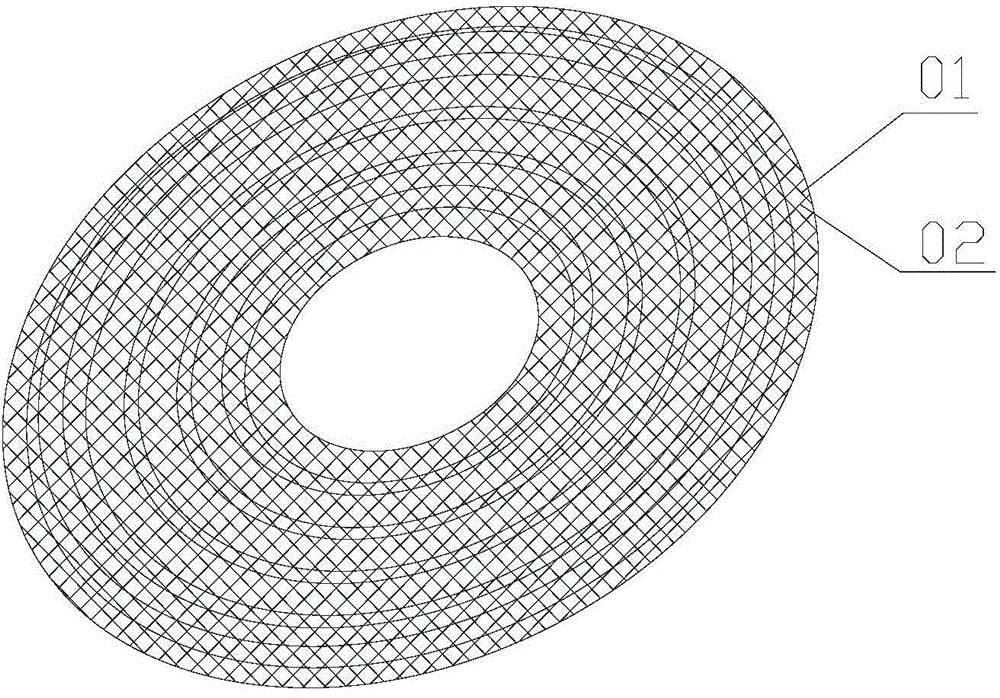

A loudspeaker and elastic wave technology, applied in the field of special elastic wave structure for speakers, can solve the problems of vibration asymmetry, inability to extend, affecting elastic wave vibration, etc., and achieve uniform centripetal pulling force and ductility, good compliance, and good recovery. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

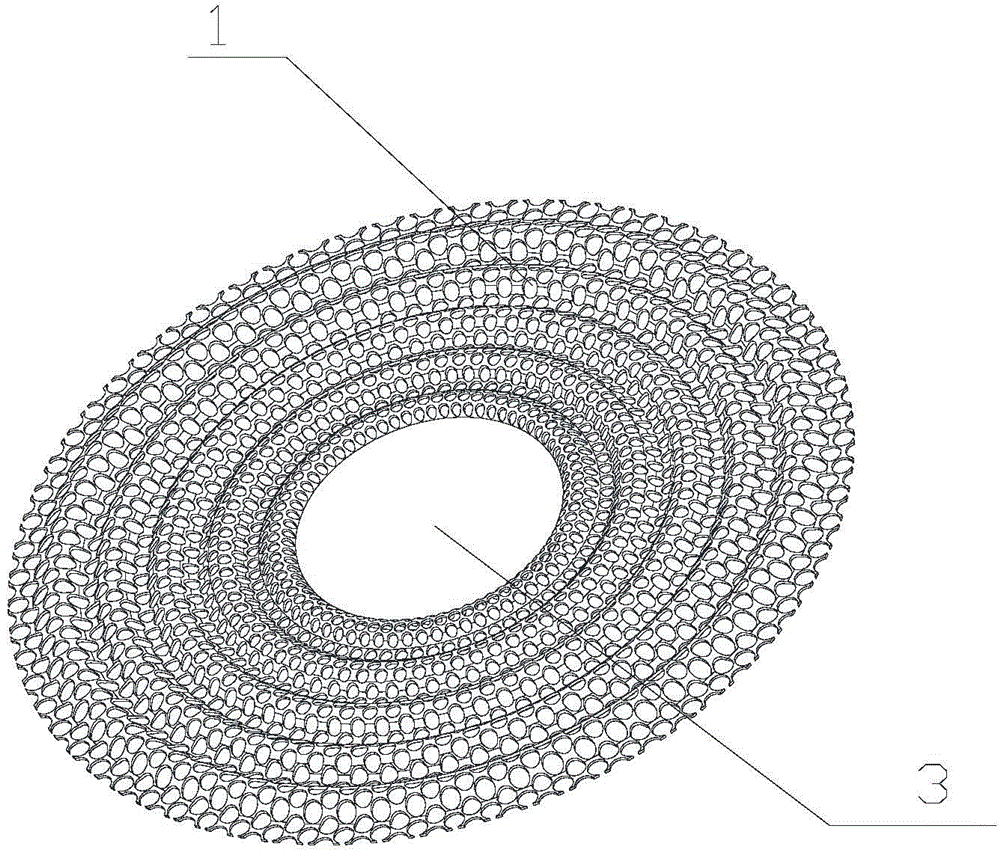

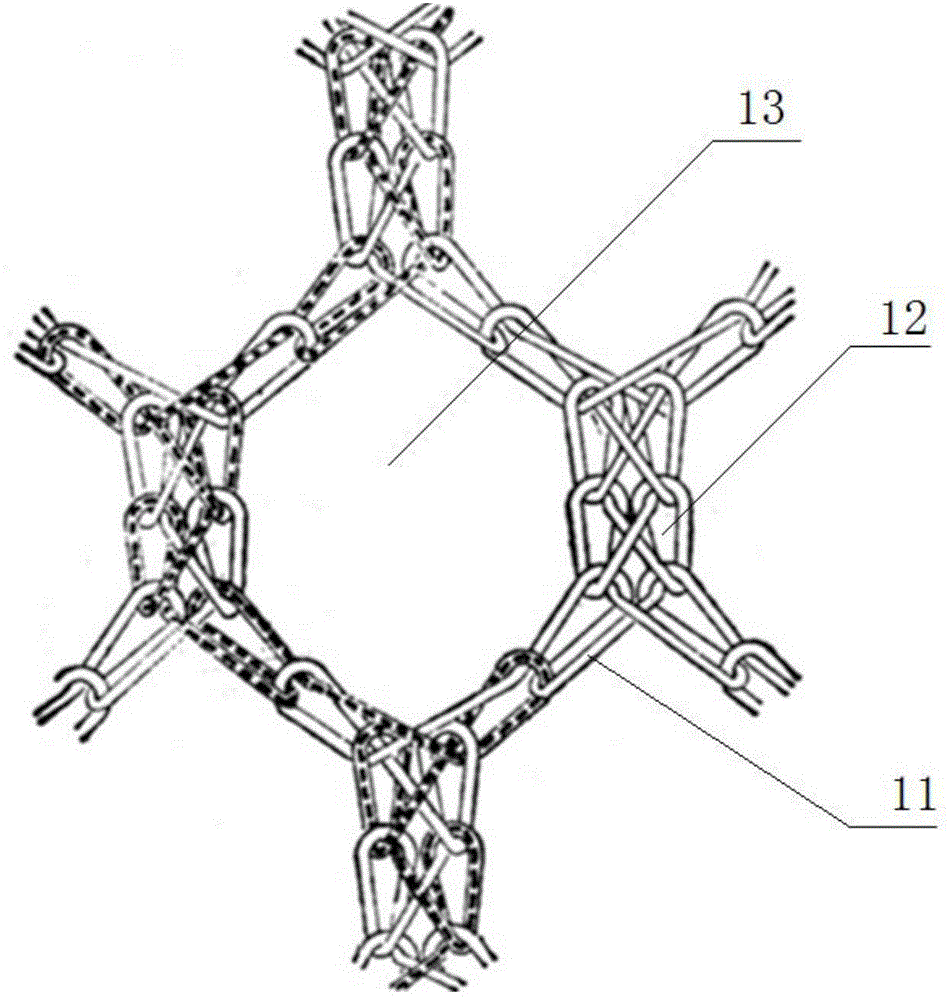

[0027] Such as figure 2 , image 3 As shown, a special elastic wave 1 for loudspeakers is a cloth structure, the cloth structure is formed by looping a plurality of warp yarns 11, and coils 12 are looped around each warp yarn. The cloth structure is circular, and a plurality of concentric rings with alternating concavities and convexities are formed on the cloth structure, and a circular mounting hole 3 is provided at the center of the cloth structure.

[0028] In this embodiment, the warp yarn is preferably made of single-strand fiber, and the material of the warp yarn is a blend of cotton and bamboo fibers. In other embodiments, the warp yarn is one or more of single-strand fiber, double-strand fiber, and multi-strand fiber; the material of the warp yarn is: cotton, bamboo fiber, bamboo charcoal fiber, polyimide chemical fiber , polymer fibers, one or more of glass fibers; not limited to this embodiment.

[0029] Wherein, a hexagonal grid-shaped mesh 13 is also provided ...

Embodiment 2

[0032] Such as Figure 5 As shown, a special elastic wave for a loudspeaker is a cloth structure, which is formed by looping and splicing a plurality of warp yarns 11, and coils 12 are looped and spliced on each warp yarn.

[0033] This embodiment provides a special elastic wave for loudspeakers. Its basic structure is consistent with that of Embodiment 1, and it also adopts a warp-knitted structure. Simple.

Embodiment 3

[0035] Such as Figure 6 As shown, a special elastic wave for a loudspeaker is a cloth structure, which is formed by looping and splicing a plurality of warp yarns 11, and coils 12 are looped and spliced on each warp yarn.

[0036] The special elastic wave for a speaker provided by this embodiment has a basic structure consistent with that of Embodiment 1, and also adopts a warp knitting structure. 12 coils.

[0037] As an equivalent implementation of this embodiment, the shape of the mesh 13 is circular or oval, which is not limited to this embodiment.

[0038] As a further illustration of the above embodiment, the fabric structure can also be used to make a loudspeaker suspension, and the manufacturing method and specific structure are similar to those of the elastic wave, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com