Pulsed ion trap transference tube with carrier gas and transference gas

An ion trap migration tube and migration gas technology, applied in the field of ion migration tubes, can solve the problems of inability to quickly switch detection modes, low detection accuracy, and high sample ion loss rate, so as to overcome the drift of characteristic ion peaks, simplify the system structure, The effect of improving system sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described below with reference to the accompanying drawings and examples.

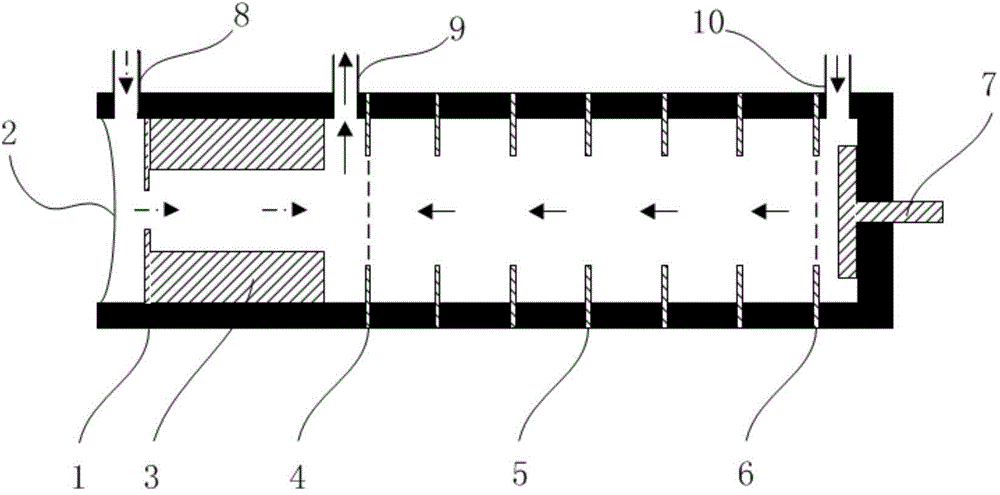

[0014] Such as figure 1 As shown, a pulsed ion trap migration tube with carrier gas and migration gas provided by the present invention includes: an insulating tube 1, a diaphragm 2, an ionization source 3, a single gate ion gate 4, a migration ring 5, a shielding grid 6 and a Faraday Disk 7.

[0015] The insulating tube 1 constitutes the outer wall of the migration tube in the present invention, and one end of the insulating tube 1 is set as an open type, and the other end is set as a closed type. In the inner cavity of the insulating tube 1, from the open end to the closed end, a diaphragm 2, an ionization source 3, a single gate ion gate 4, a transfer ring 5, a shielding grid 6 and a Faraday disk 7 are arranged in sequence, wherein the diaphra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com