Method for preparing core film of planar optical waveguide device

A planar optical waveguide and film technology, applied in the direction of optical waveguide light guide, light guide, optical components, etc., can solve the problems of increasing the refractive index of the core layer film, increasing the number of suspicious gas leakage points, increasing hardware costs, etc., achieving high refractive index, low Stress, effect of increasing refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

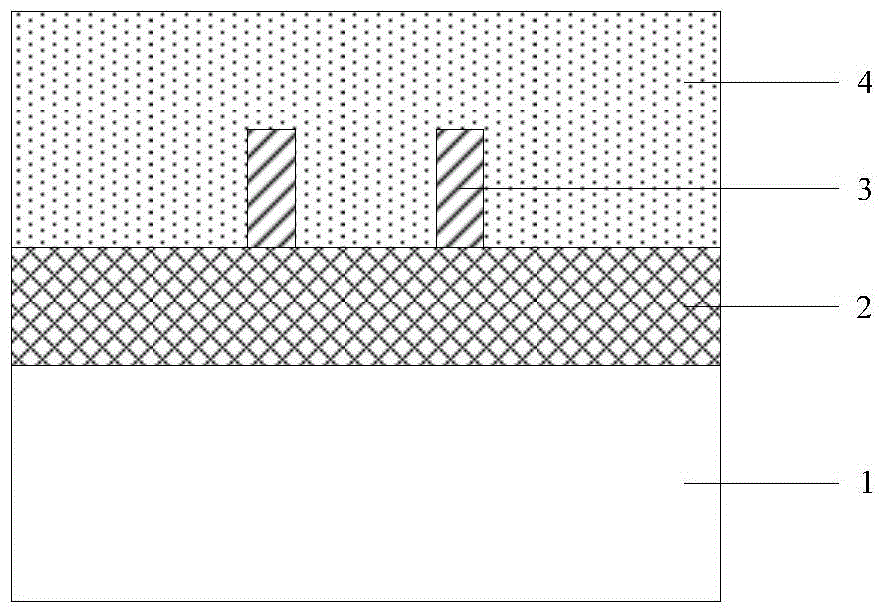

[0035] Based on this, the present invention provides a method for preparing a core film of a planar optical waveguide device to overcome the above-mentioned problems in the prior art, including:

[0036] The core film is formed by gas deposition of silane, nitrous oxide and germane;

[0037] Under certain temperature conditions, annealing is performed on the core film;

[0038] Wherein, when the gas flow rate of the silane is less than 175 sccm, the gas flow rate of the nitrous oxide is less than 3000 sccm, and the gas flow rate of the germane ranges from 12 sccm to 30 sccm, the relative ratio of the prepared core layer film to the cladding film The range of the refractive index difference is 0.75% to 1.5%.

[0039] The preparation method of the core layer film of the planar optical waveguide device provided by the present invention increases the ratio of germane in the mixed gas by reducing the gas flow rate of silane and nitrous oxide, thereby avoiding the mass flow control...

Embodiment 1

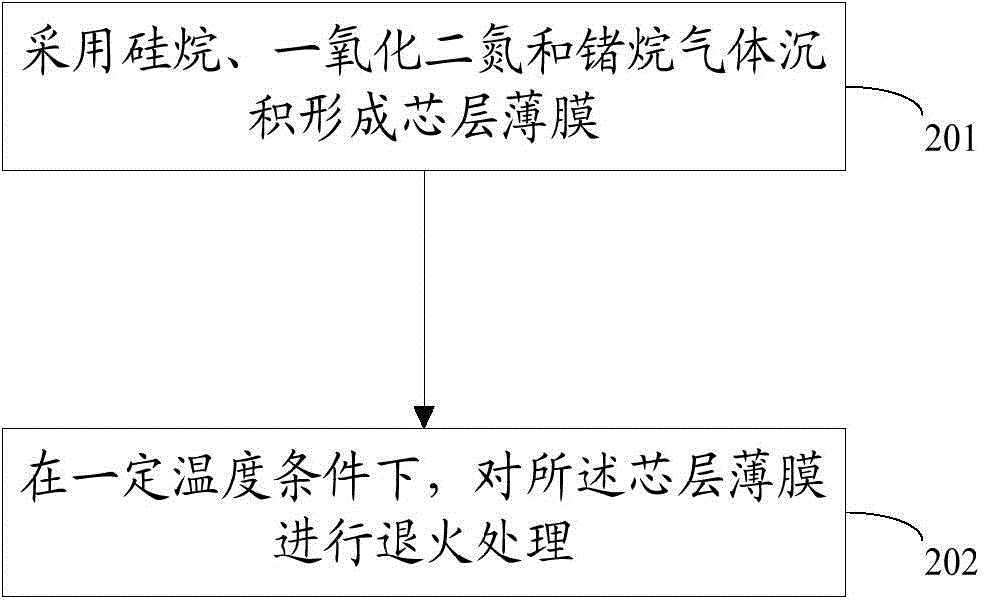

[0046] This embodiment provides a method for preparing a core film of a planar optical waveguide device, and its process flow chart is as follows figure 2 shown, including steps:

[0047]S201: forming a core film by gas deposition of silane, nitrous oxide and germane;

[0048] When PECVD is used to deposit the core layer film, it is necessary to dope germane gas in silane and nitrous oxide gas to form a germanium-doped silicon dioxide core layer film. Among them, this embodiment adopts SPTS Delta i2L type PECVD equipment to prepare the core film. The standard configuration of this equipment is to have a mass flow controller to control the flow rate of germane gas, and its plasma excitation energy is high frequency 13.56 MHz.

[0049] In this embodiment, under the condition that the gas flow rate of silane is less than 175 sccm, the gas flow rate of nitrous oxide is less than 3000 sccm, and the gas flow rate of germane is in the range of 12 sccm-30 sccm, a core layer with a t...

Embodiment 2

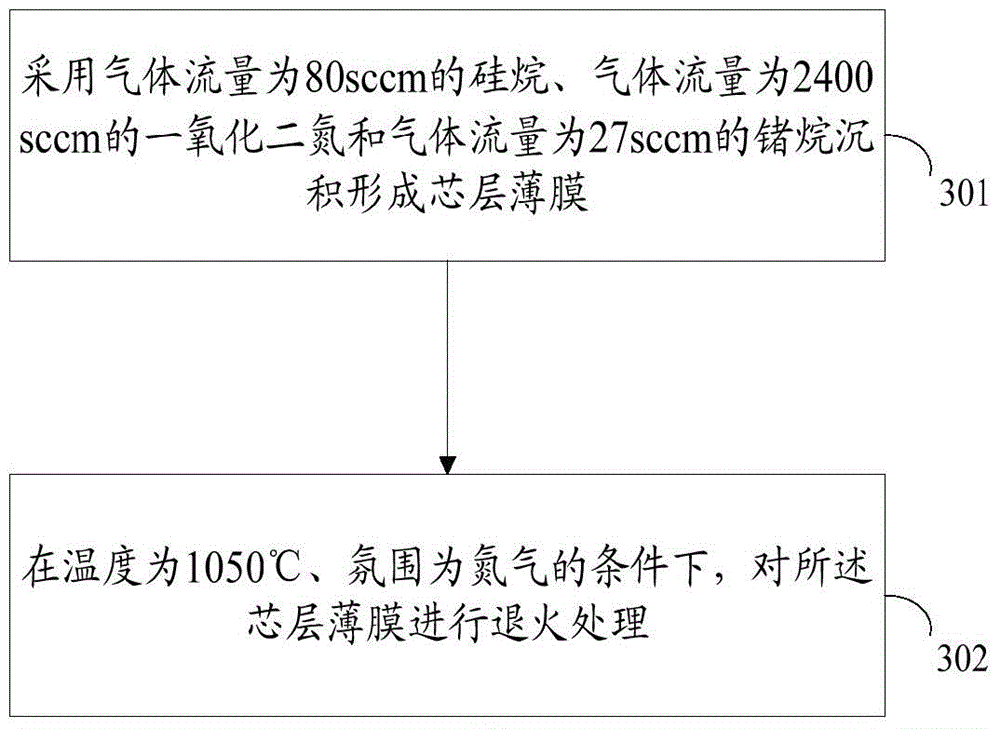

[0057] This embodiment provides a method for preparing a core film of a planar optical waveguide device, such as image 3 shown, including steps:

[0058] S301: Depositing silane with a gas flow rate of 80 sccm, nitrous oxide with a gas flow rate of 2400 sccm, and germane with a gas flow rate of 27 sccm to form a core film;

[0059] In this embodiment, the SPTS Delta i2L type PECVD equipment is used to prepare the core layer thin film. The standard configuration of this equipment is to have a mass flow controller to control the flow rate of germane gas, and its plasma excitation energy is a high-frequency 13.56 MHz.

[0060] In the present embodiment, the gas flow rate of silane is 80 sccm, the gas flow rate of nitrous oxide is 2400 sccm, and the gas flow rate of germane is 27 sccm. The parameter measurement of the obtained film performance is: the thickness of the prepared core layer film is about 6 μm, the refractive index The ratio is about 1.4688-1.4691, the uniformity of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness range | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com