Eccentric spherical externally-conical sealing structure for engine pipeline

A sealing structure and engine technology, applied in the direction of sealing surface connection, mechanical equipment, pipes/pipe joints/fittings, etc., can solve the problems of poor sealing effect, difficult repair, low oil leakage rate, etc., and achieve good sealing performance and low weight Lightweight and low chance of oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

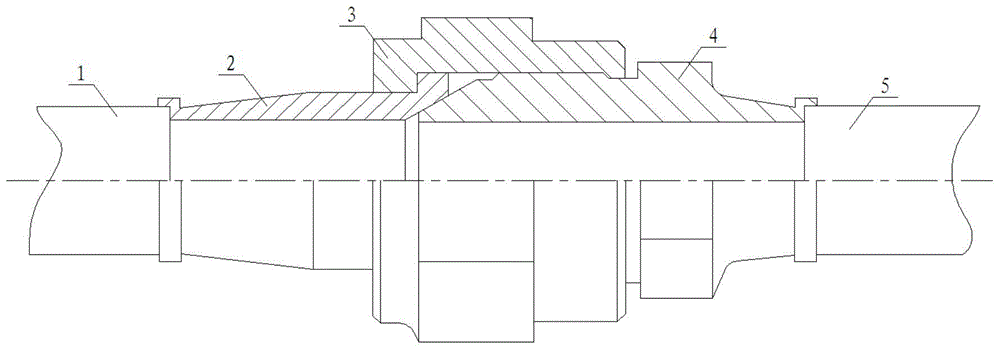

[0016] This embodiment provides a sealing structure for the eccentric spherical outer cone pipeline of the engine, including the first outer conduit 1, the flat nozzle 2, the external nut 3, the cone joint 4, the second conduit 5; one end of the external cone joint 4 It is connected with one end of the flat nozzle 2; the other end of the outer cone joint 4 is fixedly connected with the second conduit 5; the other end of the flat nozzle 2 is fixedly connected with the first conduit 1; the external nut 3 At one end of the flat nozzle 2 in the outer cone joint 4, the inner thread is tightly matched with the outer thread of the outer cone joint 4 to play the role of fixing and sealing the outer cone joint 4 and the flat nozzle 2. The matching surface of the outer cone joint 4 adopts the outer cone surface of an eccentric ball. The flat nozzle 2 is a 75° inner cone structure; the eccentric ball outer cone surface in the outer cone joint 4 cooperates with the 75° inner cone in the f...

Embodiment 2

[0021] This embodiment provides a sealing structure for an eccentric spherical outer cone pipeline of an engine, which includes an outer cone joint 4, a flat nozzle 2, an external nut 3, a second conduit 5, and a first conduit 1; the external cone joint 4 and the flat The nozzle 2 is connected, the other end of the outer cone joint 4 is welded to the second conduit 5, and the other end of the flat nozzle 2 is welded to the first conduit 1; the external nut 3 is placed in the outer cone joint 4 to flatten the end of the nozzle 2, and the inner thread is connected to the outer The outer thread of the cone joint 4 is tightened and matched, and plays the role of fixing and sealing the outer cone joint 4 and the flat nozzle 2 . The outer tapered surface adopts an eccentric ball structure to reduce the outer diameter of the part and reduce the weight of the part. When there is eccentricity in the assembly process of the outer cone joint 4 and the flat nozzle 2, it can be effectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com