Flywheel body with shock absorber

A technology of shock absorber and particle shock absorber, which is applied in the field of flywheel body, can solve the problems of complicated damping device installation, poor damping effect consistency, high time and economic cost, etc., so as to achieve shortened economic cost and time cost, small impact and good structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The flywheel body with the shock absorber according to the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

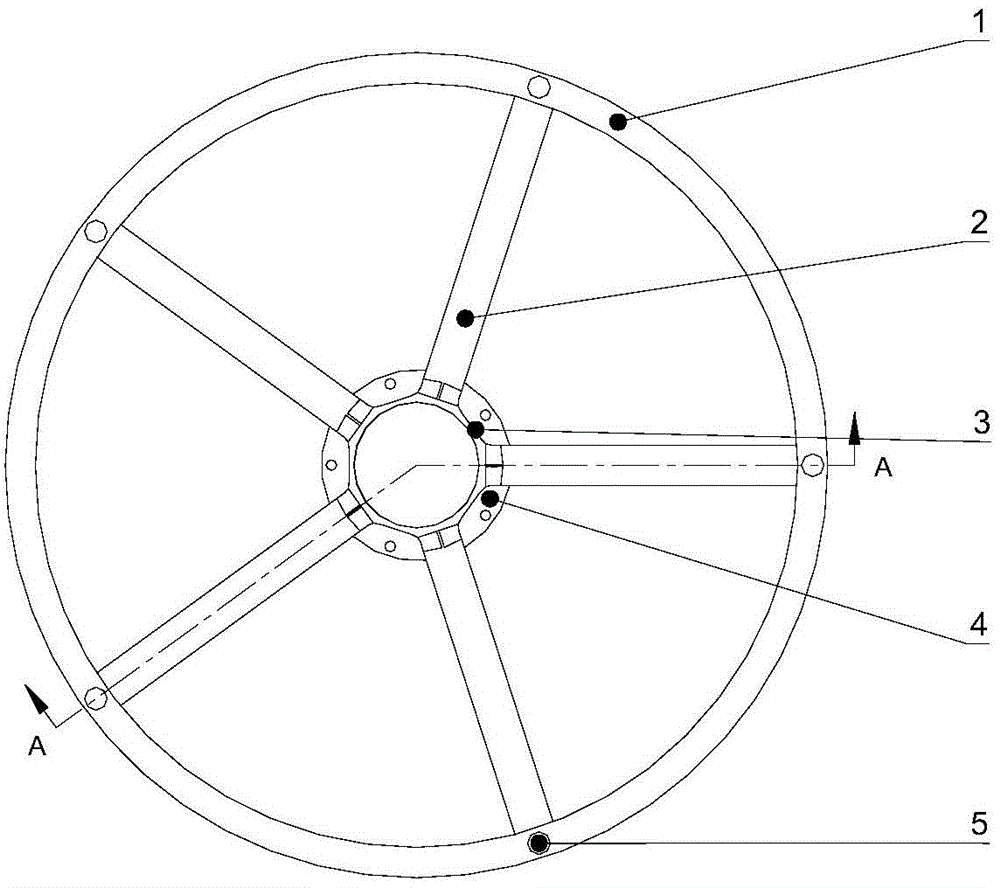

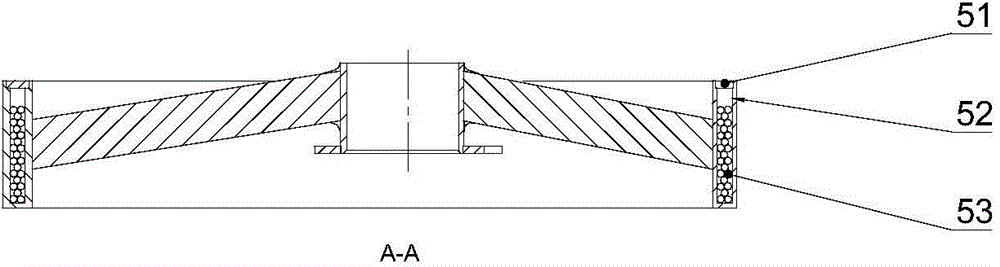

[0028] Please refer to Figure 1a with Figure 1b , The flywheel body with damper according to the present invention includes a rim 1 , spokes 2 , a hub 3 , a flange 4 arranged at one end of the hub 3 , and a particle damper 5 . Wherein, a plurality of particle dampers 5 are evenly arranged on the rim 1 , and each particle damper 5 includes a damper cavity 51 , particles or powder 52 , and a damper end cover 53 . And the shock absorber cavity 51 is arranged in the rim 1 along the axial direction, one end of the shock absorber cavity 51 has an open end, and the other end is closed. The granule or powder 52 is accommodated in the shock absorber cavity 51 ; the shock absorber end cap 53 is sealingly provided on the opening end of the shock absorber cavity 51 .

[0029] As shown in FIG. 1 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com