Axial-flow fan

An axial flow fan and fan technology, applied in the direction of cleaning methods using gas flow, components of pumping devices for elastic fluids, applications, etc., can solve the risk of exacerbating the breakage of the connecting part, affecting the stability of the fan operation, blades Large air resistance and other problems, to achieve the effect of increasing air volume and efficiency, improving power utilization, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

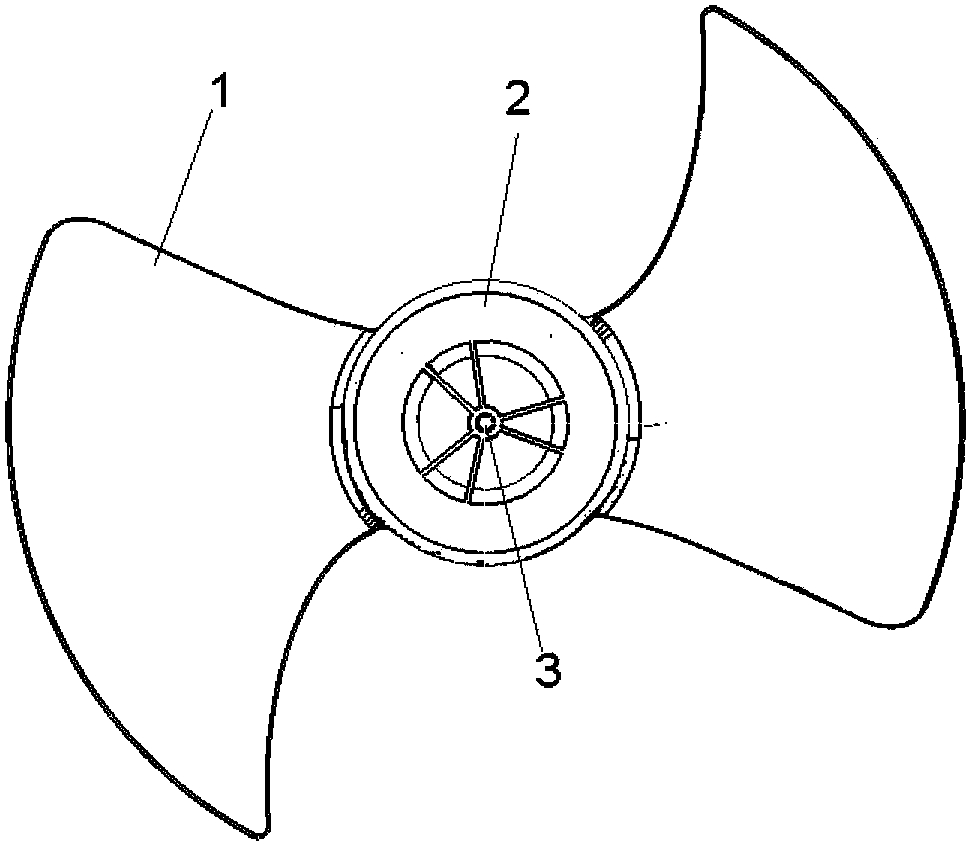

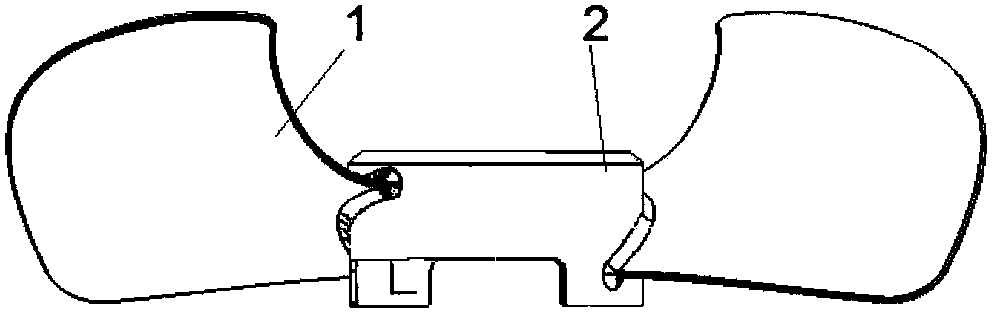

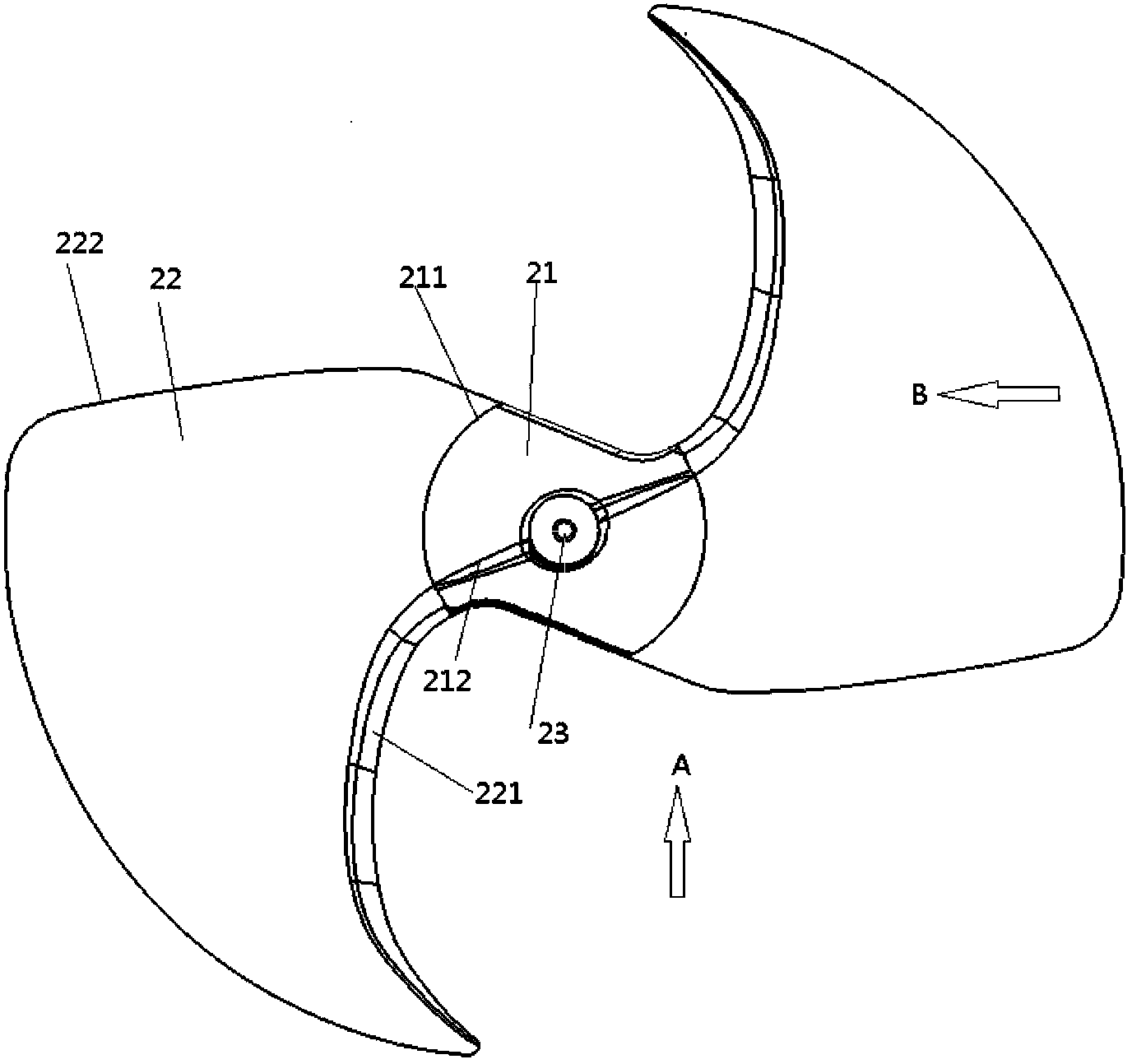

[0030] As shown in the background art, among the existing axial flow fans, for the axial flow fan with hub type, there is no wind outlet effect at the hub, so its air outlet efficiency is affected by the size of the hub area, and the material used for the hub It also increases the production cost of the axial flow fan. For the improvement of this fan, the design of the hub is canceled, and an integrally formed axial flow fan is proposed. Yet the existing hubless axial flow fan, because its joint and the joint in the middle of the fan blade are thin-walled airfoil structures that transition smoothly from the blade, due to the cancellation of the hub, the joint and the smaller rotating shaft The connection strength of the fan is greatly reduced. The thin wing design of this fan makes the fan prone to vibration during rotation, which increases the risk of breaking due to force. Moreover, due to the continuous airfoil-like structure, the wind outlet effect at the center of the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com