An automatic decoupling device for steel structure multi-section column hoisting

A technology of steel structure and section column, applied in building structure, construction, construction material processing and other directions, can solve the problems of low hoisting efficiency, high safety hazard and high labor intensity, achieve simple structure, strong applicability, and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

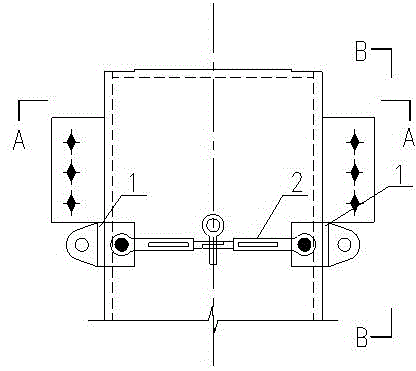

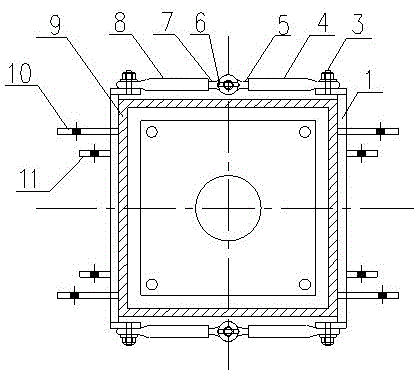

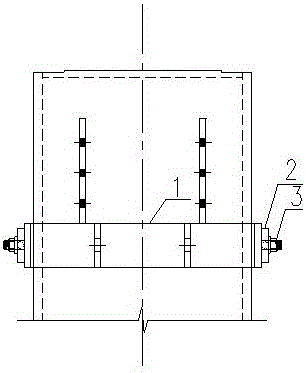

[0014] Refer to attached figure 1 , 2 , 3, the present invention comprises hoisting load-bearing hoop 1, tension adjustment mechanism 2, and hoisting load-bearing hoop is made of elongated straight plate and the connection elbow that is connected at two ends of the straight plate and is 90 degree angle with the straight plate, and there are openings on the connection elbow The shaft hole is symmetrically provided with two hoisting ear plates 11 on the hoisting hoop; the hoisting hoop can be made by welding steel plates, and can also be made of profiles. The tension adjustment mechanism is composed of the first rod-shaped adjusting long nut 4, the first adjusting screw rod 5, the second rod-shaped adjusting long nut 8, the second adjusting screw rod 7, and the limit pin with ring 6. The first rod-shaped adjusting long nut The structure is the same as that of the second rod-shaped long adjusting nut, which is provided with a screw port at one end and a shaft hole at the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com