Tea fragrant type white spirit and production process thereof

A production process and liquor technology, applied in the field of brewing, can solve the problem of low liquor yield (it can only reach 40-45%)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

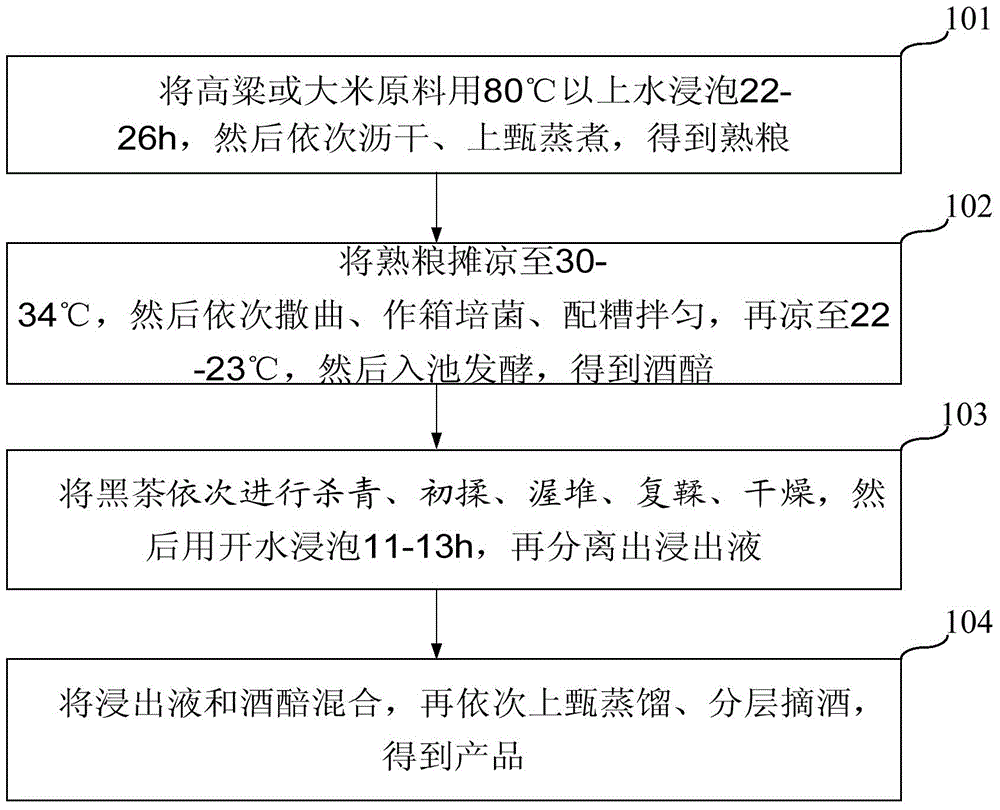

[0022] A kind of production technology of tea-flavor liquor, such as figure 1 shown, including the following steps:

[0023] Step 101: Soak the sorghum or rice raw material in water above 80°C for 22-26 hours, then drain and steam in sequence to obtain cooked grain.

[0024] Step 102: Spread the cooked grains to cool to 30-34°C, then sprinkle koji, cultivate bacteria in a box, mix well with grains, and then cool to 22-23°C, then enter the tank for fermentation to obtain fermented grains.

[0025] Step 103: The black tea is de-enzymed, first kneaded, heaped, retanned and dried in sequence, and then soaked in boiling water for 11-13 hours, and then the extract is separated.

[0026] Step 104: Mix the leaching solution and the fermented grains, and then successively carry out distillation and layer-by-layer extraction to obtain the product.

[0027] The above steps 101-102 complete the fermentation process of liquor, step 103 completes the fermentation process of dark tea, and ...

Embodiment 2

[0043] Step 1: Soak sorghum or rice raw materials in water above 80°C for 24 hours, then drain and steam for 50 minutes, take out the cooked grains and let it cool to 32°C, spread koji, mix well with 0.4% koji, and then cultivate bacteria in the box (24-26h), add 1:3 blending grains and mix well, blow to cool to 22-23°C, enter the tank for fermentation, and the fermentation period is 6-7 days.

[0044] Step 2: After fermenting the dark tea leaves, soak them in boiling water at about 90°C (tea water ratio 1:10) and mix well. Stir once every 4 hours. After soaking for 12 hours, separate the tea leaves from the extract and sterilize them for later use.

[0045] The third step: mix the fermented wine grains with the black tea extract, and then go up to the distillation, pick the wine layer by layer, and store it in grades.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com