Energy-saving automatic material overturning lime calcining kiln

An automatic turning and calcining kiln technology, applied in lime production and other directions, can solve the problems of poor quality of finished lime, high heat consumption of lime shaft kiln, short kiln lining life, etc. The effect of enhancing the calcination capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

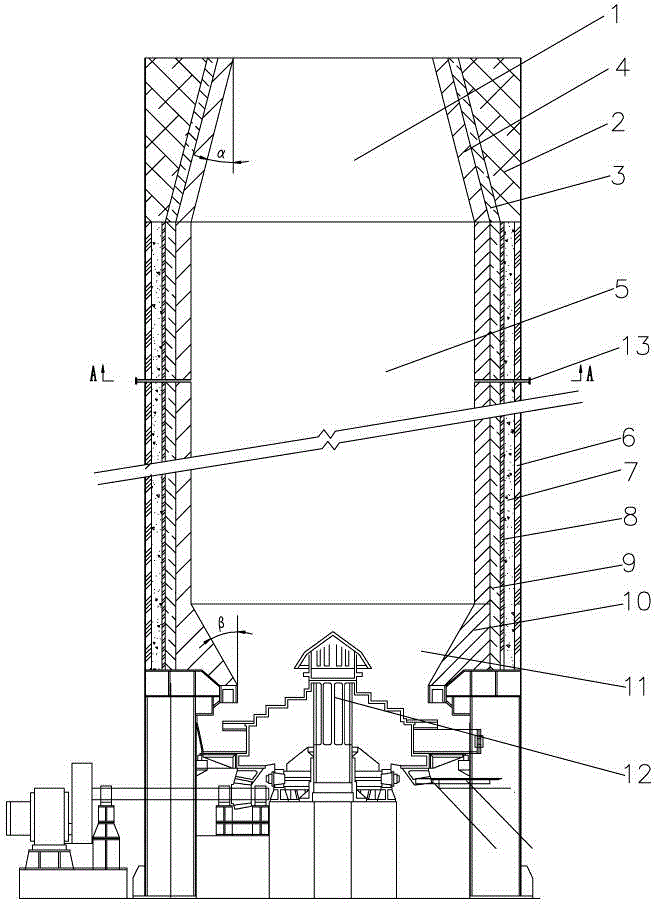

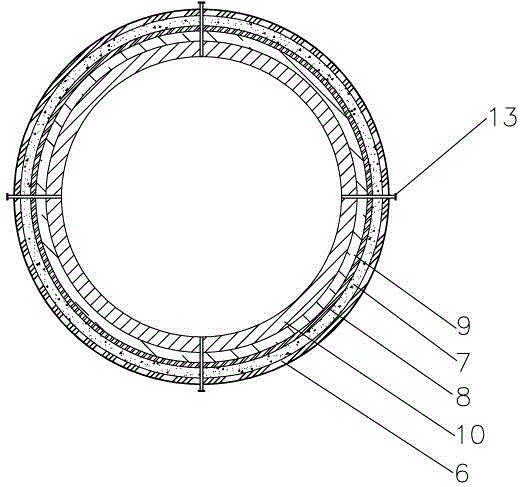

[0014] see figure 1 , 2 , the present invention has a kiln body and a discharge device installed at the bottom of the kiln body, particularly: the kiln body is divided into three sections, the upper section is a waste gas outlet section 1, the middle section is a firing section 5, and the lower section is a discharge section 11, The firing section 5 is further divided into a preheating zone, a calcination zone and a cooling zone, wherein the inner wall of the exhaust gas outlet section 1 is a tapered necking structure, and the angle α between the conical surface and the center line is 15°±1°, and the exhaust gas The diameter difference between the large and small openings of the outlet section 1 is 1000±200mm (determined according to the overall size of the kiln body, this embodiment is 1000mm, that is, the diameter of the small opening is 3800mm, and the diameter of the large opening is 4800mm). The firing section 5 is a cylindrical structure. The inner wall of section 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com