A driving mechanism of a medium-package machine

A driving mechanism and driving motor technology, applied in packaging machines, packaging, transportation and packaging, etc., can solve the problems of large power consumption, large space occupation, and insufficient action completion, so as to reduce power consumption and prolong service life , the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

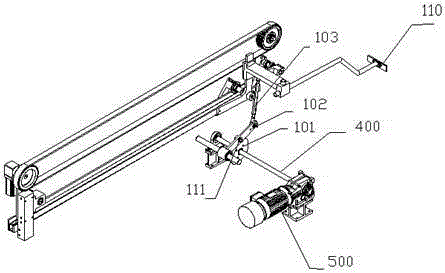

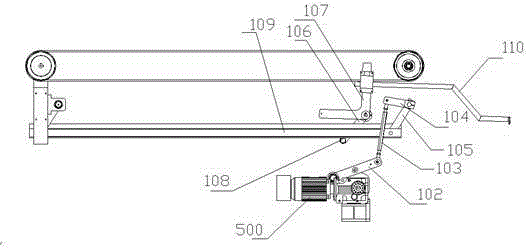

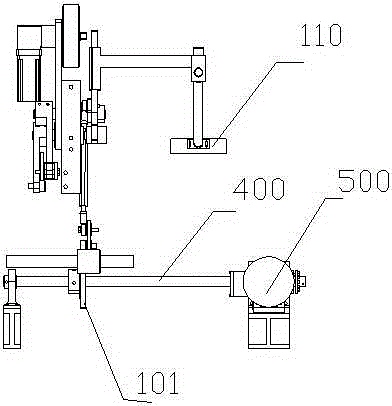

[0059] Such as Figure 1 to Figure 4 As shown, the forward and backward movement of the push rod of the tundish machine provided in this embodiment is completed by the following mechanism:

[0060] The mechanism includes a driving motor 500 and a camshaft 400. The camshaft 400 is connected to the driving motor 500. It also includes a push bag cam 101, a push bag first swing arm 102, a push bag link 103, a push bag second swing arm 104, Push bag third swing arm 105, push bag fourth swing arm 106, push bag fifth swing arm 107, roller 108 and pressure plate 109.

[0061] The bag pushing cam 101 is sleeved on the camshaft 400, one end of the bag pushing first swing arm 102 is hinged on the frame of the tundish machine, and the other end is connected with one end of the bag pushing link 103, and the other end of the bag pushing link 103 One end is connected to one end of the second swing arm 104 of the push bag, the other end of the second swing arm 104 is connected to one end of the th...

Embodiment 2

[0069] Such as Figure 5 to Figure 8 As shown, the lifting and falling actions of the bag suction rod of the tundish bag machine provided in this embodiment are completed by the following mechanism:

[0070] The mechanism includes a suction bag cam 201, a suction bag first swing arm 202, a suction bag link 203 and a suction bag second swing arm 204. The suction bag cam 201 is sleeved on the cam shaft 400, and the suction bag first One end of the swing arm 202 is hinged to the frame of the tundish machine, the other end is connected to one end of the suction bag link 203, and the other end of the suction bag link 203 is connected to the second swing arm 204 of the suction bag. One end of the swing arm 204 is hinged on the frame of the tundish machine, and the other end is connected with the bag suction rod 205 of the tundish machine.

[0071] A suction bag tension spring is connected to the first swing arm 202 of the suction bag, and the other end of the suction bag tension spring i...

Embodiment 3

[0077] Such as Picture 9 As shown, the forward and backward movement of the claw-opening component of the tundish machine provided in this embodiment is completed by the following mechanism:

[0078] The mechanism includes a claw-opening cam 301, a claw-opening swing arm 302, and a claw-opening link 303. The claw-opening cam 301 is sleeved on the camshaft 400, and one end of the claw-opening arm 302 is hinged on the frame of the tundish machine. The other end is connected to one end of the claw opening link 303, and the other end of the claw opening link 303 is connected to the claw opening part of the tundish machine.

[0079] The claw opening swing arm 302 is connected with a claw opening tension spring, and the other end of the claw opening tension spring is fixed on the frame of the tundish machine.

[0080] The claw opening swing arm 302 is provided with a claw opening roller 304, and the claw opening roller 304 is tangent to the claw opening cam 301.

[0081] The principle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com