Middle packaging machine

A technology of chartering and pushing the bag, which is applied in the field of medium charter, can solve the problems that the material cannot reach the specified position accurately, cannot be packed, and occupies a large space, so as to shorten the deformation recovery time, avoid the inaccuracy in place, and reduce the packaging space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

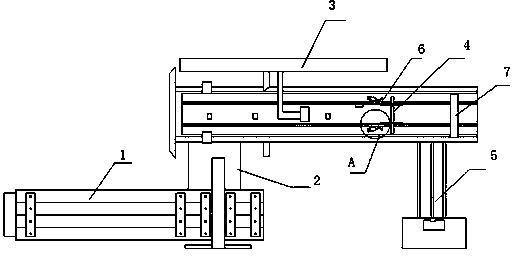

[0065] The present invention provides a medium bag machine, which includes a material sorting mechanism 1, a bag pushing mechanism 3, a bag suction mechanism 4, a bag feeding mechanism 5, a bag opening mechanism 6 and a sealing mechanism 7. The improvements of the present invention are: It also includes a flattening mechanism 2, the material sorting mechanism 1 is sent to the flattening mechanism 2 after the material is sorted out, and after being flattened by the flattening mechanism 2, it is sent to the pushing bag path of the bag pushing mechanism 3, and the bag feeding mechanism 5 will A plurality of packaging bags are divided into individual packaging bags and sent below the suction bag rod 44 of the suction bag mechanism 4. After the suction bag rod 44 of the suction bag mechanism 4 sucks up and opens the packaging bag, the opening claw 60 of the bag opening mechanism 6 will open the packaging bag. Stretch out, the pushing block 36 of the bag pushing mechanism 3 will push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com