Medium charter

A charter and rack technology, applied in the field of medium charter, can solve the problems of high height of the pushing device, inconvenient inspection and maintenance, etc., and achieve the effects of convenient inspection and maintenance, preventing back and forth movement, and reducing potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

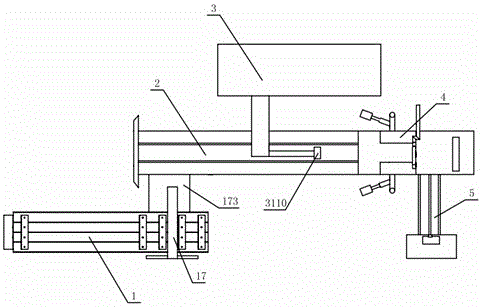

[0101] The bagging machine includes a material sorting device 1, a bag pushing conveyor belt 2, a bag pushing device 3, a suction bag opening device 4 and a bag feeding device 5, the material sorting device 1 is connected with the bag pushing conveyor belt 2, and the bag pushing conveyor belt 2 is connected with the bag pushing device 3, the bag pushing conveyor belt 2 is connected with the suction bag opening device 4, the suction bag opening device 4 is connected with the bag feeding device 5, and the bag pushing device 3 is arranged on one side of the bag pushing conveyor belt 2 side.

[0102] When the present invention is in use, the existing bag pushing device 3 can be arranged on one side of the bag pushing conveyor belt 2, so that inspection and maintenance are convenient.

Embodiment 2

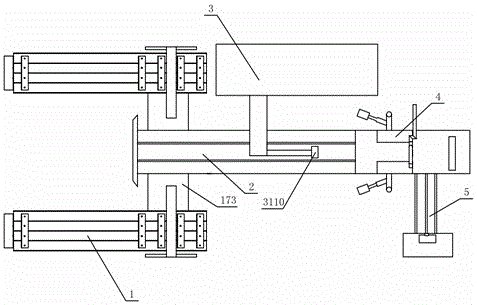

[0104] The bagging machine includes a material sorting device 1, a bag pushing conveyor belt 2, a bag pushing device 3, a suction bag opening device 4 and a bag feeding device 5, the material sorting device 1 is connected with the bag pushing conveyor belt 2, and the bag pushing conveyor belt 2 is connected with the bag pushing device 3, the bag pushing conveyor belt 2 is connected with the suction bag opening device 4, the suction bag opening device 4 is connected with the bag feeding device 5, and the bag pushing device 3 is arranged on one side of the bag pushing conveyor belt 2 side.

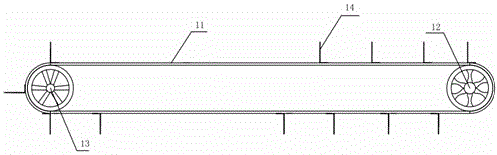

[0105] In the present invention, the material handling device 1 includes a material handling channel, and the material handling channel includes a material handling conveyor belt 11, a driving wheel 12, a driven wheel 13, a driving shaft, a driven shaft, a transmission member 16, a drive motor 15 and Clamping plate 14, described driving shaft links to each other with driving motor 15 by tran...

Embodiment 3

[0125] The bagging machine includes a material sorting device 1, a bag pushing conveyor belt 2, a bag pushing device 3, a suction bag opening device 4 and a bag feeding device 5, the material sorting device 1 is connected with the bag pushing conveyor belt 2, and the bag pushing conveyor belt 2 is connected with the bag pushing device 3, the bag pushing conveyor belt 2 is connected with the suction bag opening device 4, the suction bag opening device 4 is connected with the bag feeding device 5, and the bag pushing device 3 is arranged on one side of the bag pushing conveyor belt 2 side.

[0126] In the present invention, the material handling device 1 includes a material handling channel, and the material handling channel includes a material handling conveyor belt 11, a driving wheel 12, a driven wheel 13, a driving shaft, a driven shaft, a transmission member 16, a drive motor 15 and Clamping plate 14, described driving shaft links to each other with driving motor 15 by tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com