Downwards-blowing air conditioner system for engineering machine

A technology for air-conditioning systems and construction machinery, which is applied in air-handling equipment, heating/cooling equipment, transportation, and packaging, etc. Frost can not be used normally, reduce performance, reduce the effect of failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

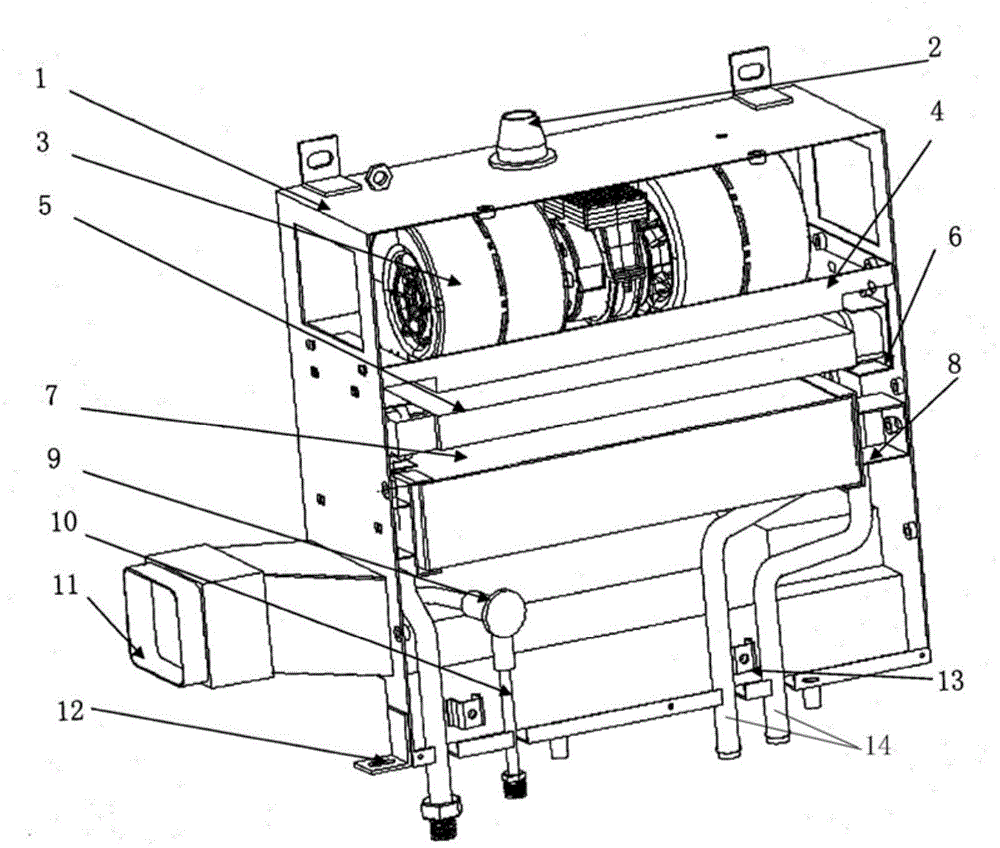

[0012] The object of the present invention is to provide a down-blown air conditioning system for construction machinery. The specific implementation of the present invention will be described in detail below with reference to the accompanying drawings.

[0013] figure 1 As shown, a rubber sleeve 2 is arranged on the top surface of the air-conditioning box 1, and the double-impeller centrifugal fan 3 is defined on the fan support 4 in the upper part of the air-conditioning box 1. Below the fan support 4, the warm air core support 6 is fixed on the air-conditioning box. On the inner wall of the body 1, and support the warm air core 5; the evaporator core 7 is fixed under the warm air core support 6 by the evaporator core support 8, and the pipe clamp support 13 connects the refrigerant pipeline 10 of the air conditioning system and the condensation The water pipe 14 is supported on the inner wall of the air conditioning box 1, the refrigerant pipeline 10 and the condensate wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com