Automatic stamp-pad ink painting device of stamping machine

A technology of stamping machine and ink, applied in printing, stamping and other directions, can solve problems such as non-compliance with ergonomic requirements, long stamping cycle, prone to mechanical failures, etc., to achieve efficient design, simple and ingenious design structure , the effect of taking up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

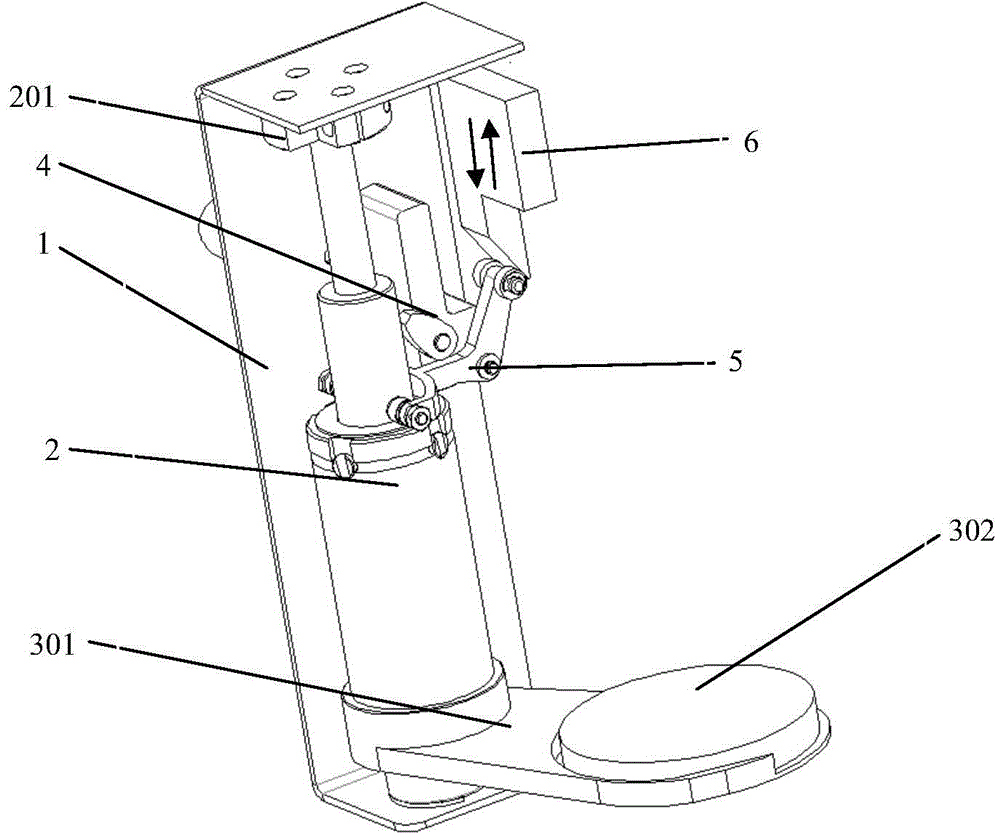

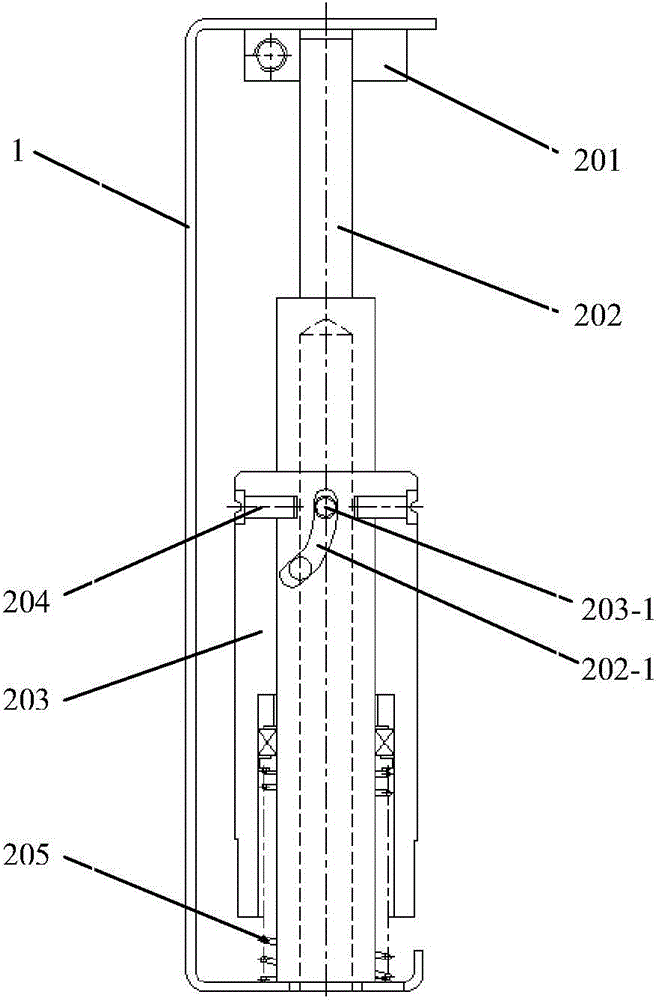

[0027] The ink automatic smearing device of the stamping machine in this example, such as figure 1 As shown, the structure includes a mounting frame body 1, a sliding mechanism 2, an ink tray 301, an ink tray 302, and a driving mechanism. The sliding mechanism (2) and the driving mechanism are all installed on the mounting frame body (1). The tray (302) is fixed on the shaft sleeve (203) of the sliding mechanism (2), the ink tray (302) is arranged on the ink tray (301), and the driving mechanism and the sliding mechanism (2) are contact-fitted.

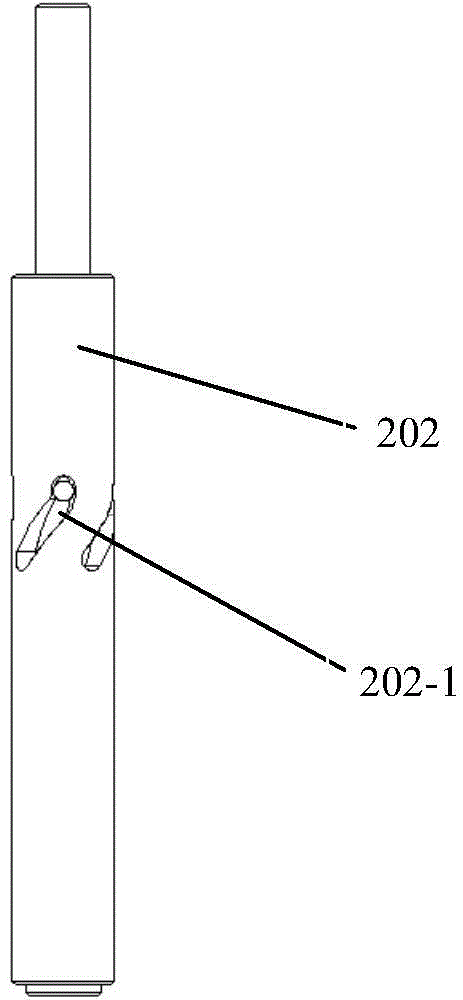

[0028] Specifically, the sliding mechanism 2, such as Figure 2-3 As shown, it includes a sliding shaft 202, a shaft sleeve 203, and an elastic mechanism 205 fixed on the mounting bracket body 1 by means of a fixing flange 201. The sliding shaft 202 is evenly provided with four spiral grooves 202-1, and the shaft The sleeve 203 is provided with a through hole 203-1 corresponding to the helical groove 202-1, with the help of the dial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com