Alarm-capable mixing mill

A mixing mill and mixing grinding technology, which is applied in the direction of solid separation, filter screen, grid, etc., can solve the problem of inclusion of refractory aggregates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

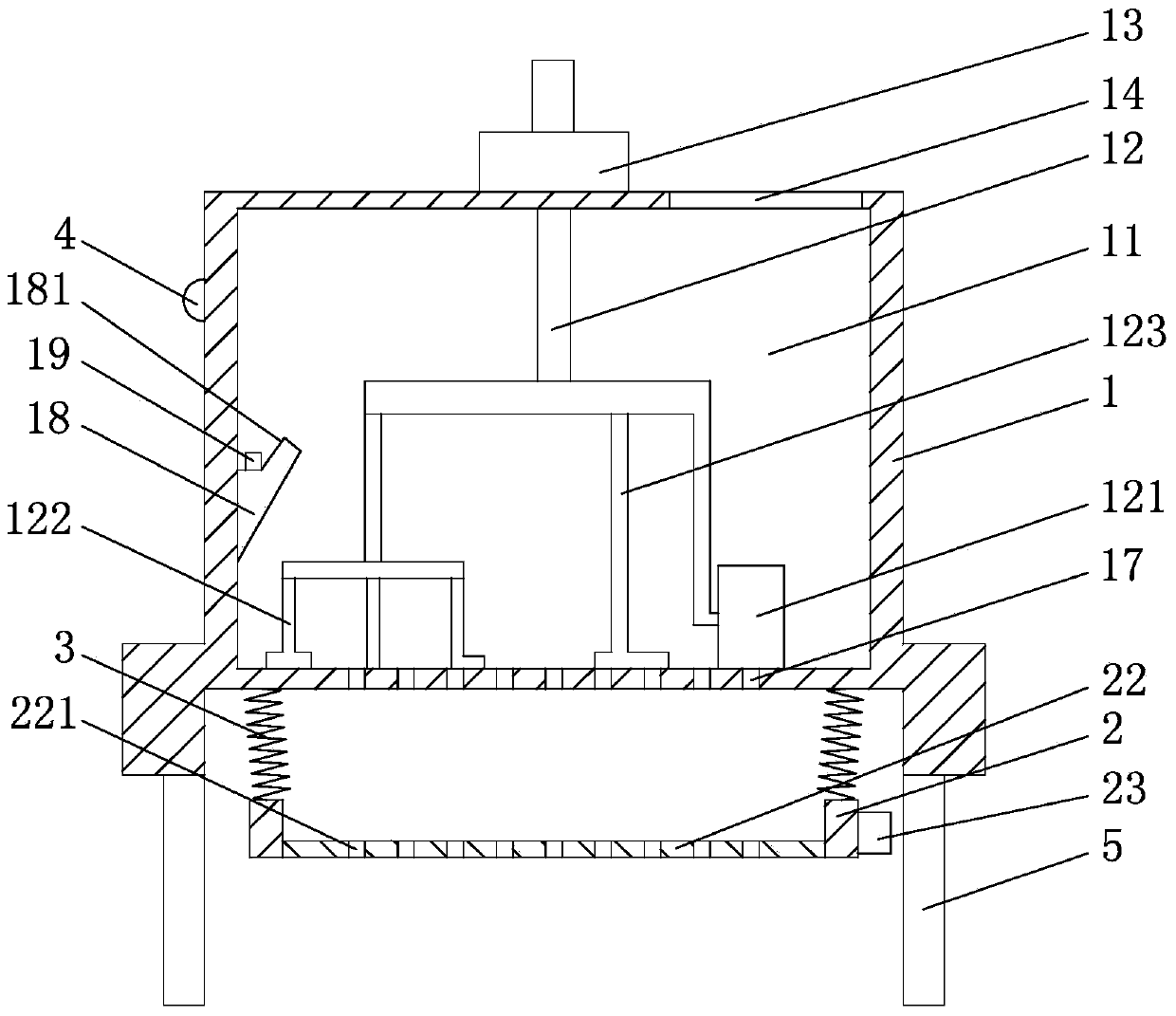

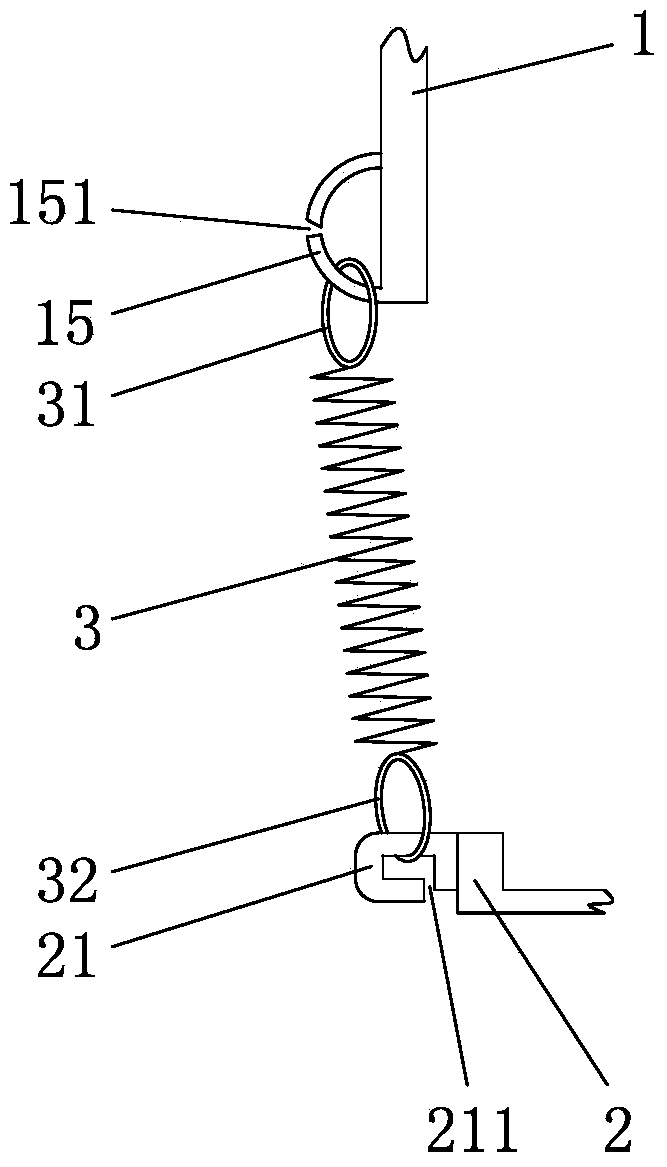

[0019] refer to figure 1 and figure 2 , an alarmable mixing mill, including a casing 1, four support columns 5 are evenly arranged on the lower end face of the casing 1, a material port 14 and a motor 13 are arranged on the upper end face of the casing 1, and the refractory aggregate is The material port 14 enters into the mixing and grinding tank 11 , and an alarm 4 is provided on the side wall of the casing 1 . The casing 1 is provided with a mixing and grinding tank 11. The mixing and grinding tank 11 is provided with a main shaft 12, a rolling wheel 121, a stirring rod 122, and a scraper 123. The motor 13 drives the rolling wheel 121, stirring rod 122, and scraper 123 through the main shaft 12. The three rotate in the mixing drum 11 .

[0020] The side wall of the mixing drum 11 is provided with a baffle 18, and the baffle 18 is provided with an inductive switch 19. The included angle between the side wall 181 of the baffle 18 and the side wall of the mixing tank 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com