Valley filling circuit

A technology of valley filling circuit and rectification circuit is applied in the field of rectification and filtering to achieve the effects of low cost, small size and low working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

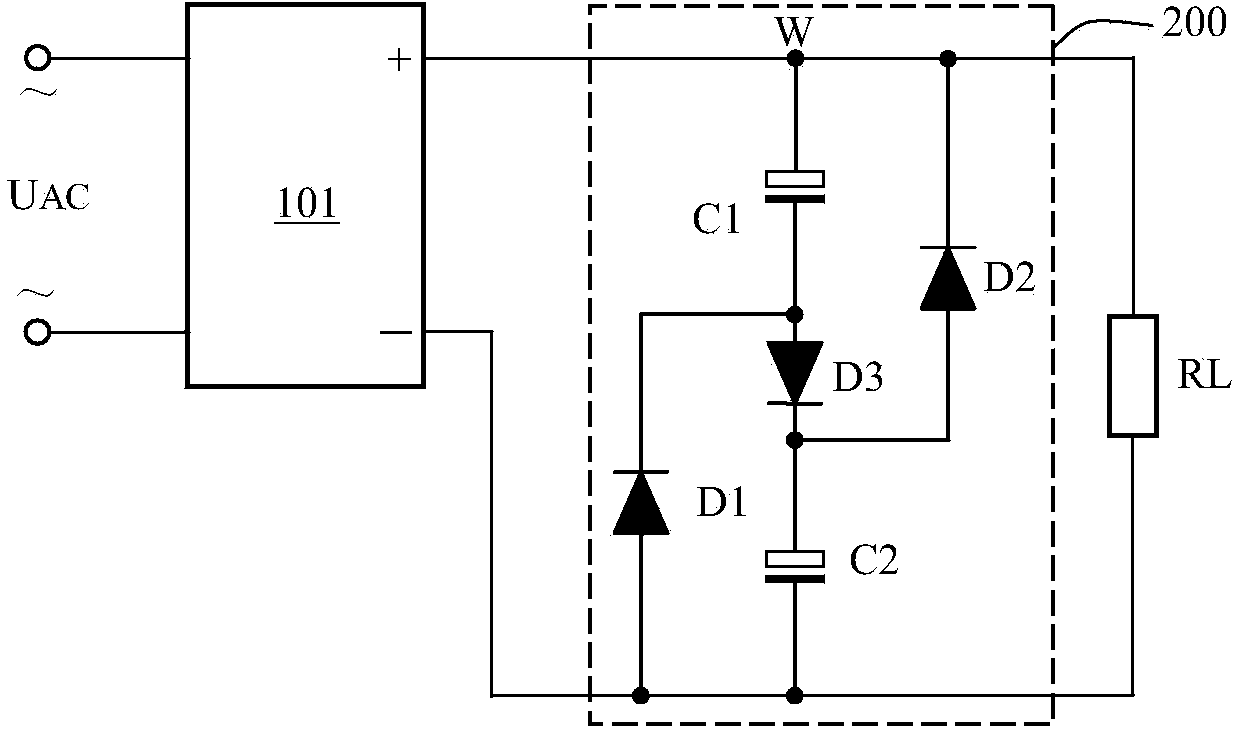

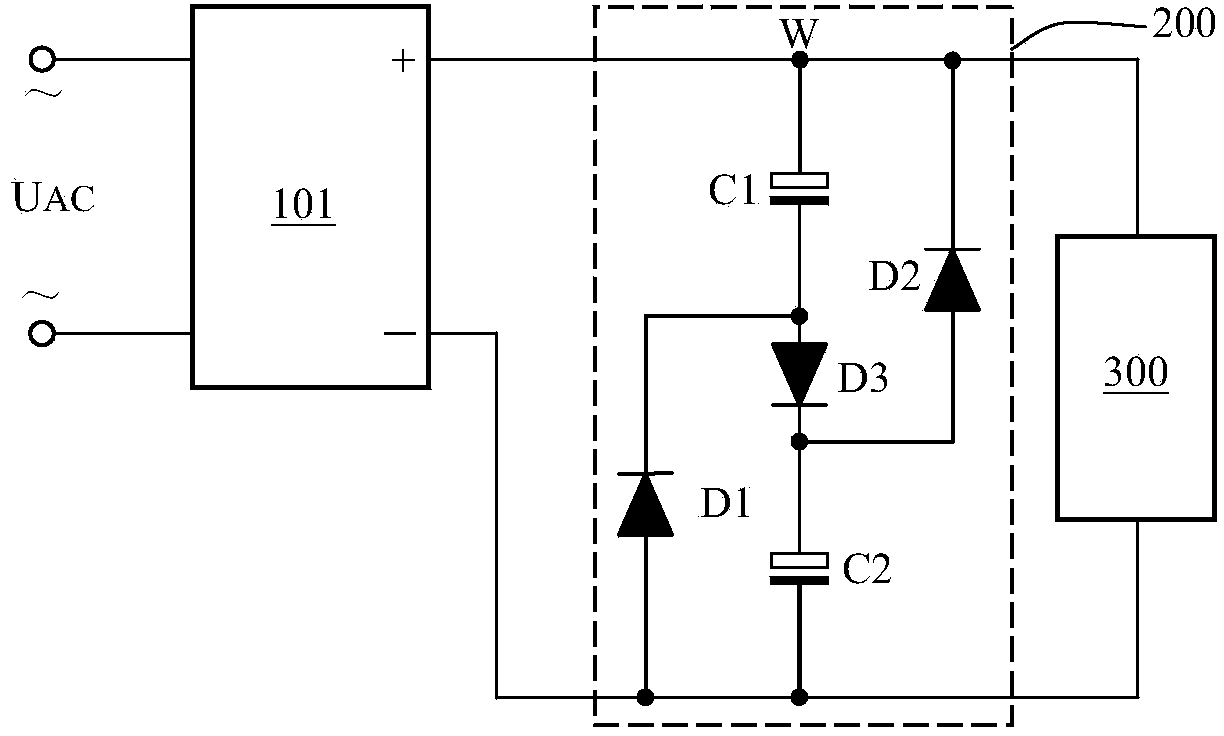

[0041] Figure 5 The schematic diagram of the valley filling circuit of the first embodiment is shown, a valley filling circuit 201 is used to be connected between the rectifier circuit 101 and the flyback circuit 300, including

[0042] The first capacitor C1 and the first diode D1, the anode of the first capacitor C1 is connected to the positive output terminal of the preceding rectifier circuit, the cathode of the first capacitor C1 is connected to the cathode of the first diode D1, and the first diode D1 The anode of the anode is connected to the negative output terminal of the pre-stage rectifier circuit;

[0043] The second capacitor C2 and the second diode D2, the cathode of the second capacitor C2 is connected to the anode of the first diode D1, the anode of the second capacitor C2 is connected to the anode of the second diode D2, and the second diode D2 The cathode of the first capacitor C1 is connected to the positive pole;

[0044] a third diode D3, the anode of t...

no. 2 example

[0076] Image 6 Shows the circuit schematic diagram of the second embodiment, a valley filling circuit 201', which differs from the first embodiment in that it further includes a resistor R1, which is connected in series with a diode D3 to form a two-terminal device, the two-terminal The device replaces the diode D3 in the first embodiment, and keeps the current direction of the diode D3 unchanged, that is, the function of the charging diode D3 to charge the capacitors C1 and C2 only when the AC current is close to the peak value remains unchanged. The resistor R1 is connected in series with the diode D3, and the capacitor C3 is connected in parallel to both ends of the two-terminal device formed by connecting the first resistor R1 and the third diode D3 in series. The resistor R1 connected in series with the diode D3 is used to improve when the input AC voltage is close to the peak value. The pulse width of the charging current further improves the power factor of the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com