Double-sided packaging method of high-power laser bar and sintering fixture used for high-power laser bar packaging

A high-power laser and high-power technology, applied in the structural details of semiconductor lasers, lasers, laser components, etc., can solve the problems of exposed light-emitting surface of the bar, light blocking at the edge of the heat sink, etc., to achieve a wide range of applications, Solve the packaging problem and solve the effect of blocking the beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

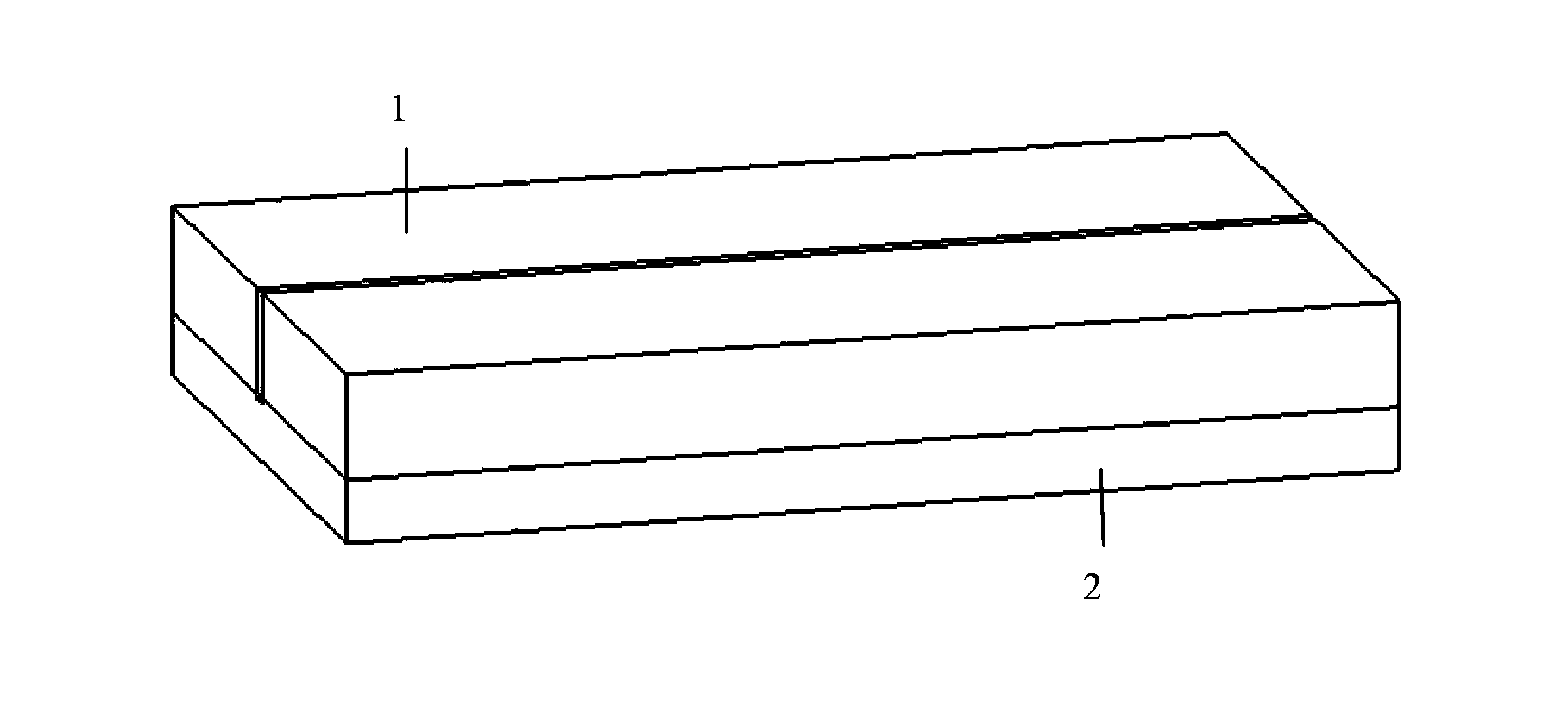

[0033] Such as Figure 1-2 shown.

[0034] A method for double-sided packaging of a high-power laser bar, the method adopts a sintering fixture to package the high-power laser bar, and the method includes the following steps:

[0035] (1) Align the light-emitting surface of the high-power laser bar with the sides of the two first heat sinks 1 along the sintering fixture; the first heat sink is an oxygen-free copper heat sink, and the surface is plated with gold;

[0036] (2) welding one of the first heat sinks 1 to one side of the high-power laser bar, and welding the other first heat sink 1 to the other side of the high-power laser bar; During the welding process, the two first heat sinks 1 are aligned and clamped by a sintering jig.

[0037]Before the step (1), a high-power laser bar is installed on the insulating area of the insulating ceramic substrate 2 according to the prior art; a patterned metal layer is provided on one side of the insulating ceramic substrate 2, a...

Embodiment 2

[0040] A method for double-sided packaging of high-power laser bars as described in Embodiment 1, the difference is that a metal layer is arranged on the other side of the insulating ceramic substrate 2, and a second metal layer is fixedly arranged on the metal layer. Heat sink. The second heat sink is an oxygen-free copper heat sink with a gold-plated surface.

Embodiment 3

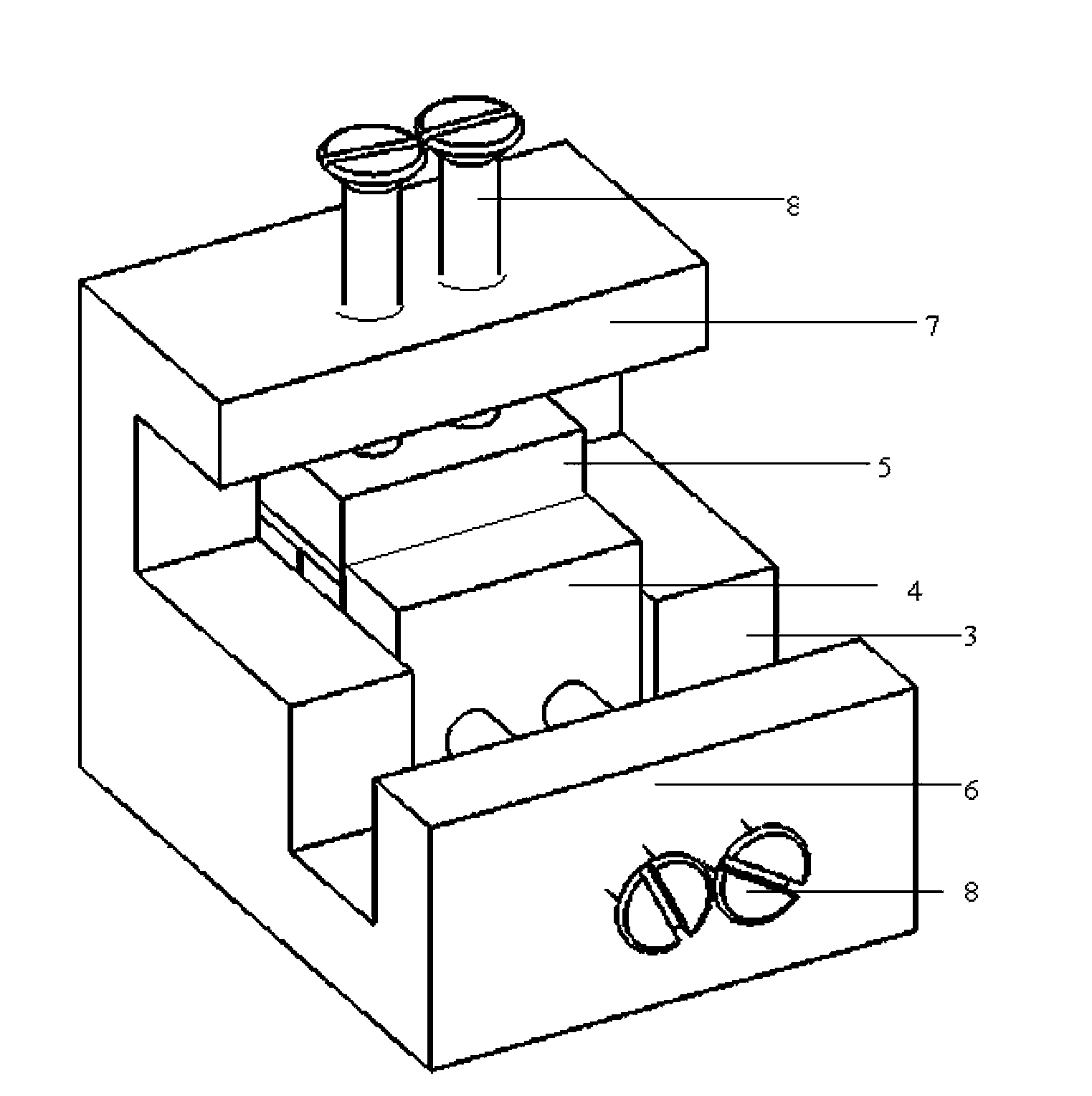

[0042] A sintering jig for the packaging method described in Embodiment 1, comprising a heating body 3, an upper baffle 7 fixedly arranged above the heating body 3, a front baffle 6 fixedly arranged in front of the heating body 3, an upper The backing plate 5 and the front backing plate 4, the upper backing plate 5 and the upper baffle plate 7 are arranged to move in parallel, and are used to fix the first heat sink and the insulating ceramic substrate, and the front backing plate 4 and the The front baffle 6 is arranged to move in parallel, and is used to fix the high-power laser bar and the first heat sink.

[0043] The upper backing plate 5 is arranged parallel to the upper baffle plate 7 through fixing screws 8 . The front backing plate 4 is arranged parallel to the front baffle plate 6 through the fixing screws 8 . The heating body 3, the upper baffle 7 and the front baffle 6 of the sintering fixture are all made of oxygen-free copper. Both the front backing plate 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com