Workshop layout method for complex job of simulating human cell evolution

A job shop, human cell technology, used in instruments, manufacturing computing systems, data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

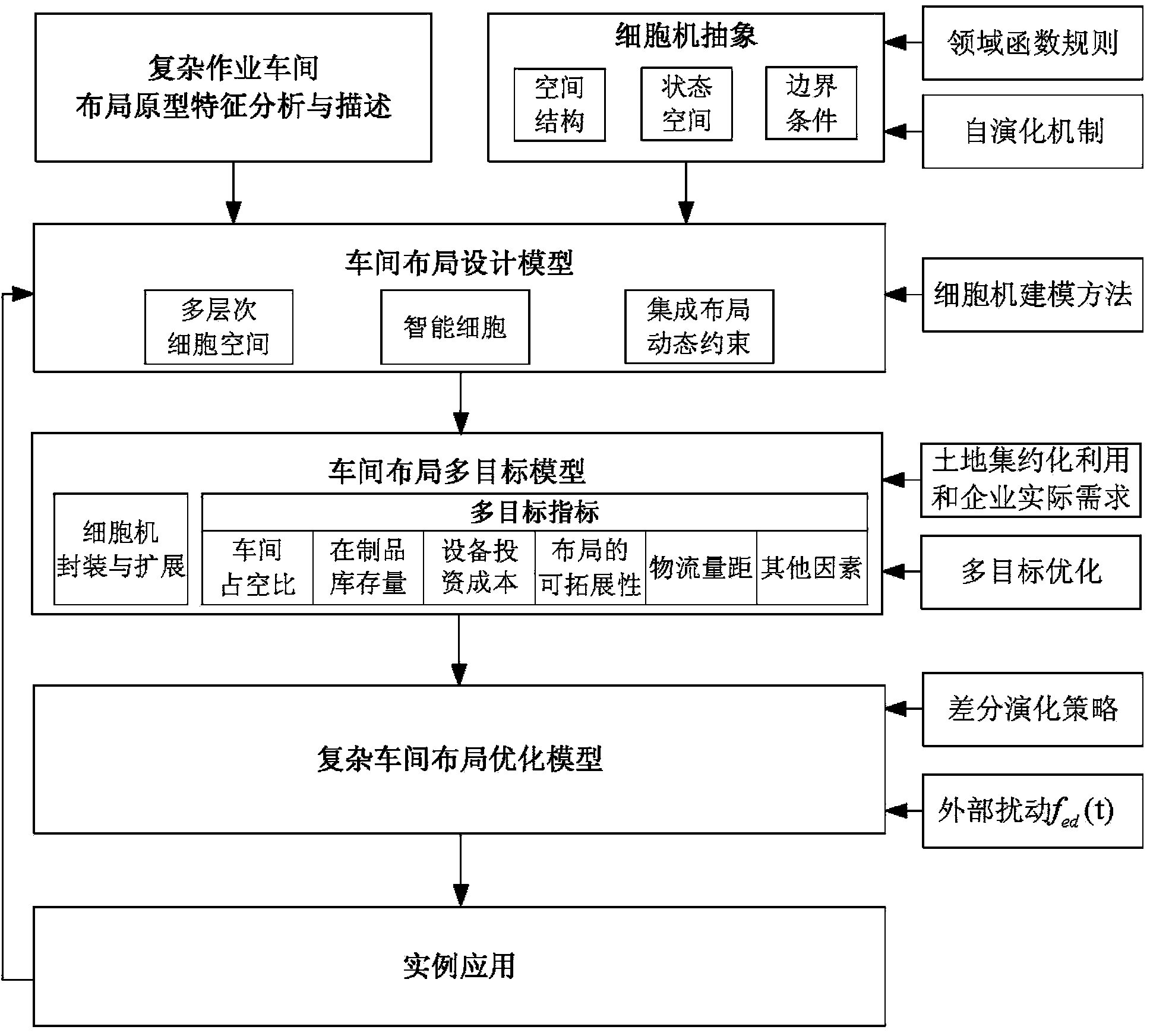

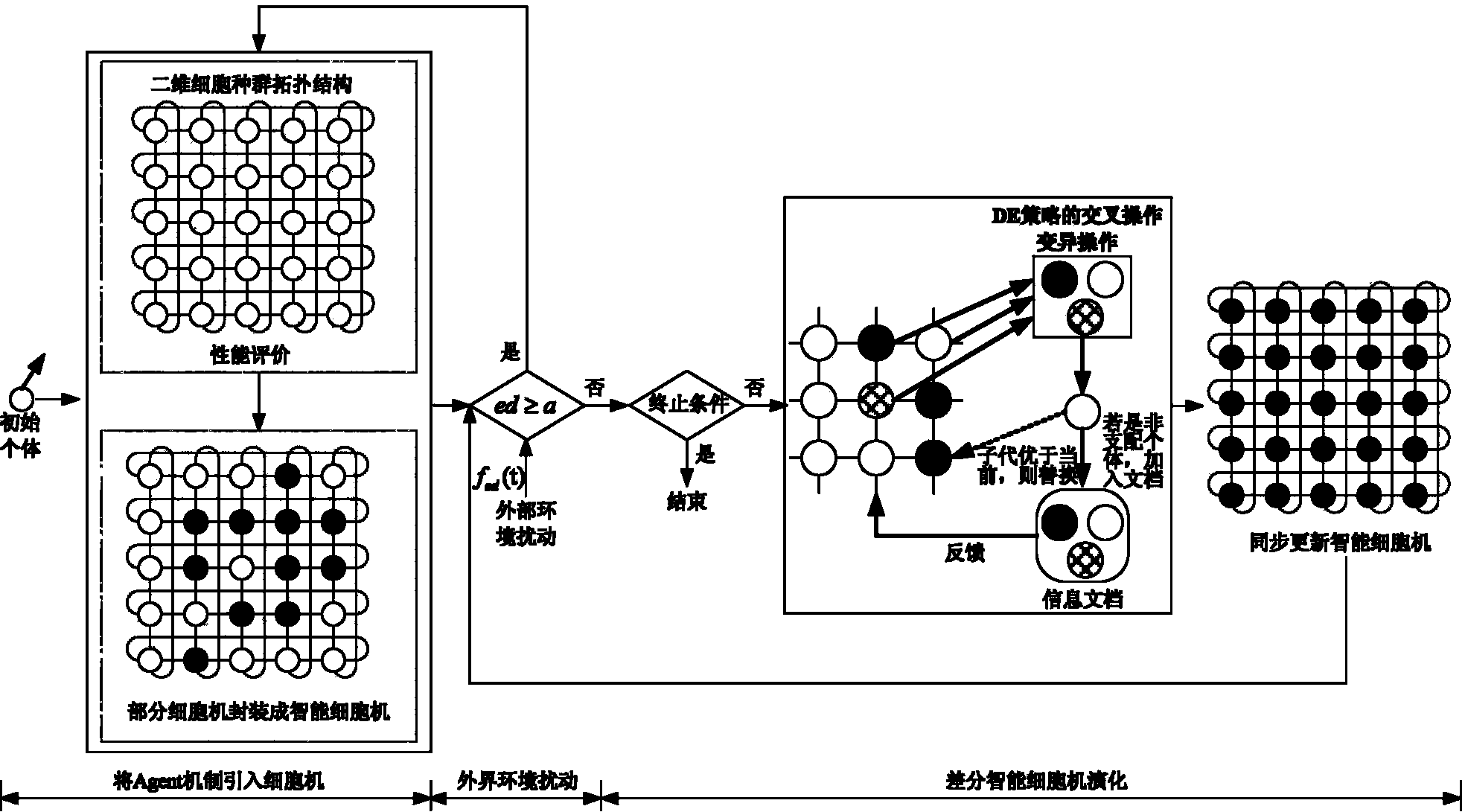

Method used

Image

Examples

specific example

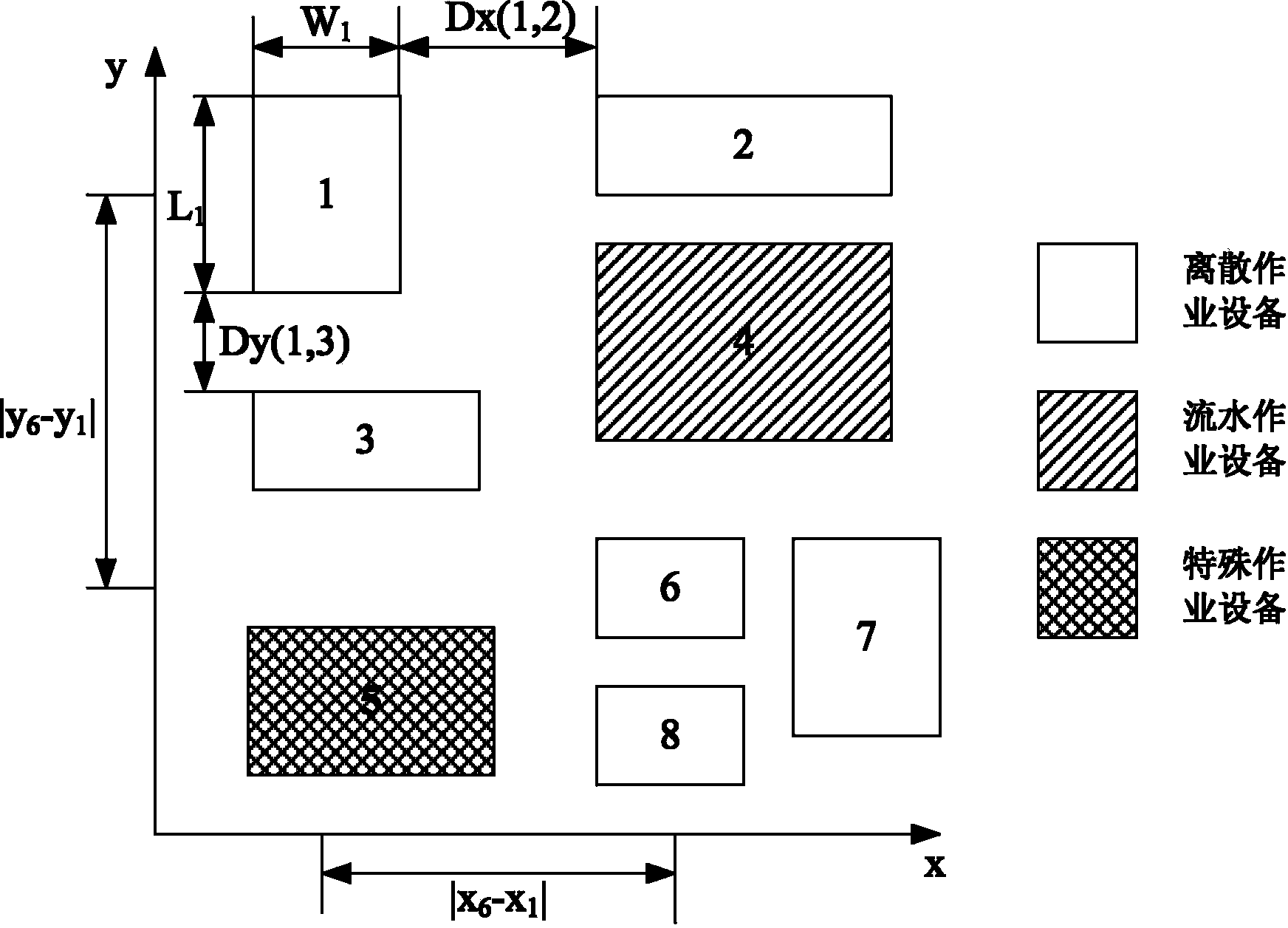

[0117] Taking an export-oriented home appliance manufacturing enterprise as an example, by the end of 2013, there were 116 types of vacuum cleaners produced in 12 categories, and the variety of products was still increasing; the parts required for the production of each category were quite different, and the process The routes are different. For example, there are 632 sets of molds for the production of related plastic parts; the output of each type of product reaches 189,000 pieces / month, and the minimum is 16,000 pieces / month. The company currently has three comprehensive production workshops, each with an area of 15,000 square meters (200 meters x 75 meters), each workshop includes machining, injection molding, welding, heat treatment, polishing, laser engraving, pre-assembly, parts assembly, General assembly, workshop distribution warehouse, mold warehouse, work-in-progress buffer and other areas. The layout of the workshop is arranged according to experience and has bee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com