Modularized Bluetooth monitoring system applied to 3D printing equipment

A 3D printing and monitoring system technology, applied in the field of communication systems, can solve problems such as loss, eye function damage, blindness, etc., and achieve the effect of ensuring safety, long processing time, and high environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the examples and drawings, but the implementation of the present invention is not limited thereto.

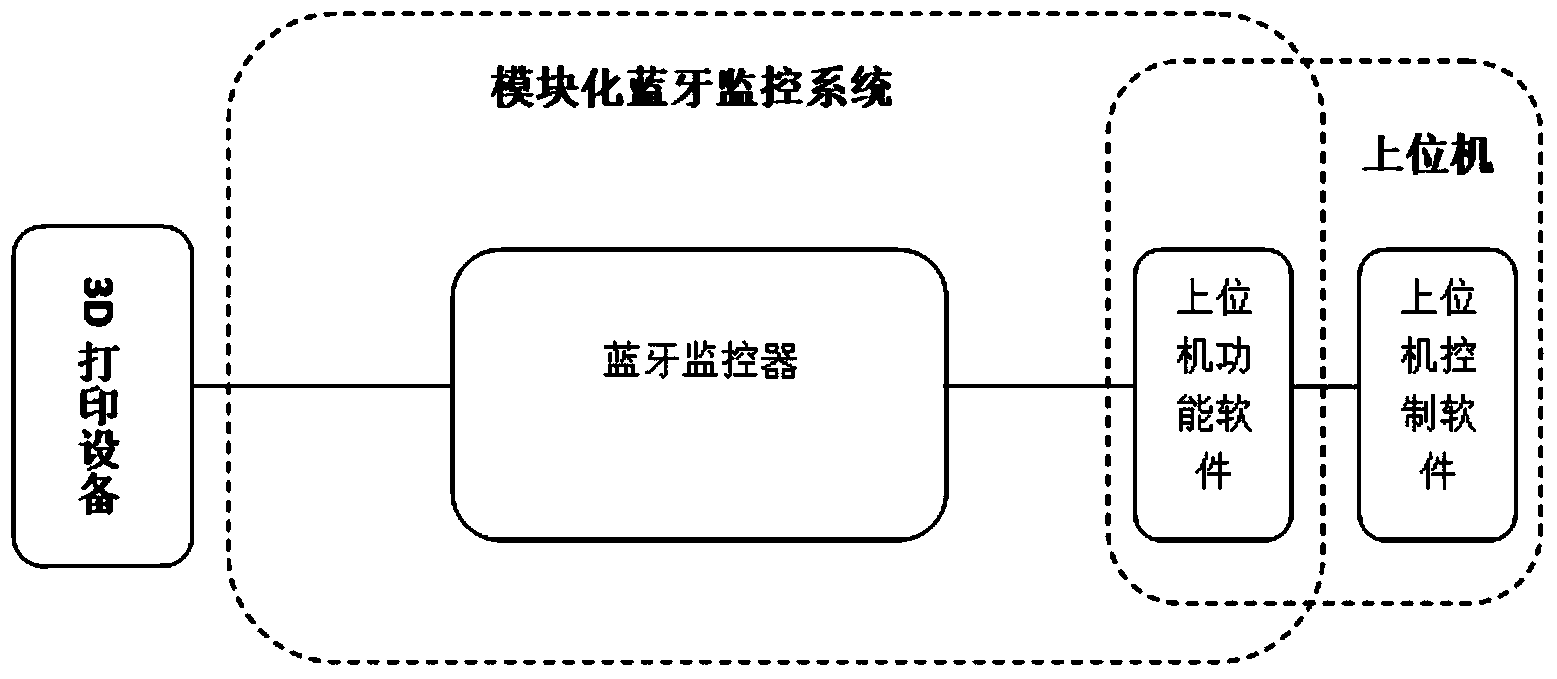

[0030] Such as figure 1 , A modular Bluetooth monitoring system applied to 3D printing equipment, including a Bluetooth monitor and a host computer connected in sequence, the Bluetooth monitor is connected to the 3D printing device through a serial port, the Bluetooth monitor is connected to the host computer through Bluetooth, and the Bluetooth monitor Collect and transmit environmental data, machine code and equipment status information to the host computer;

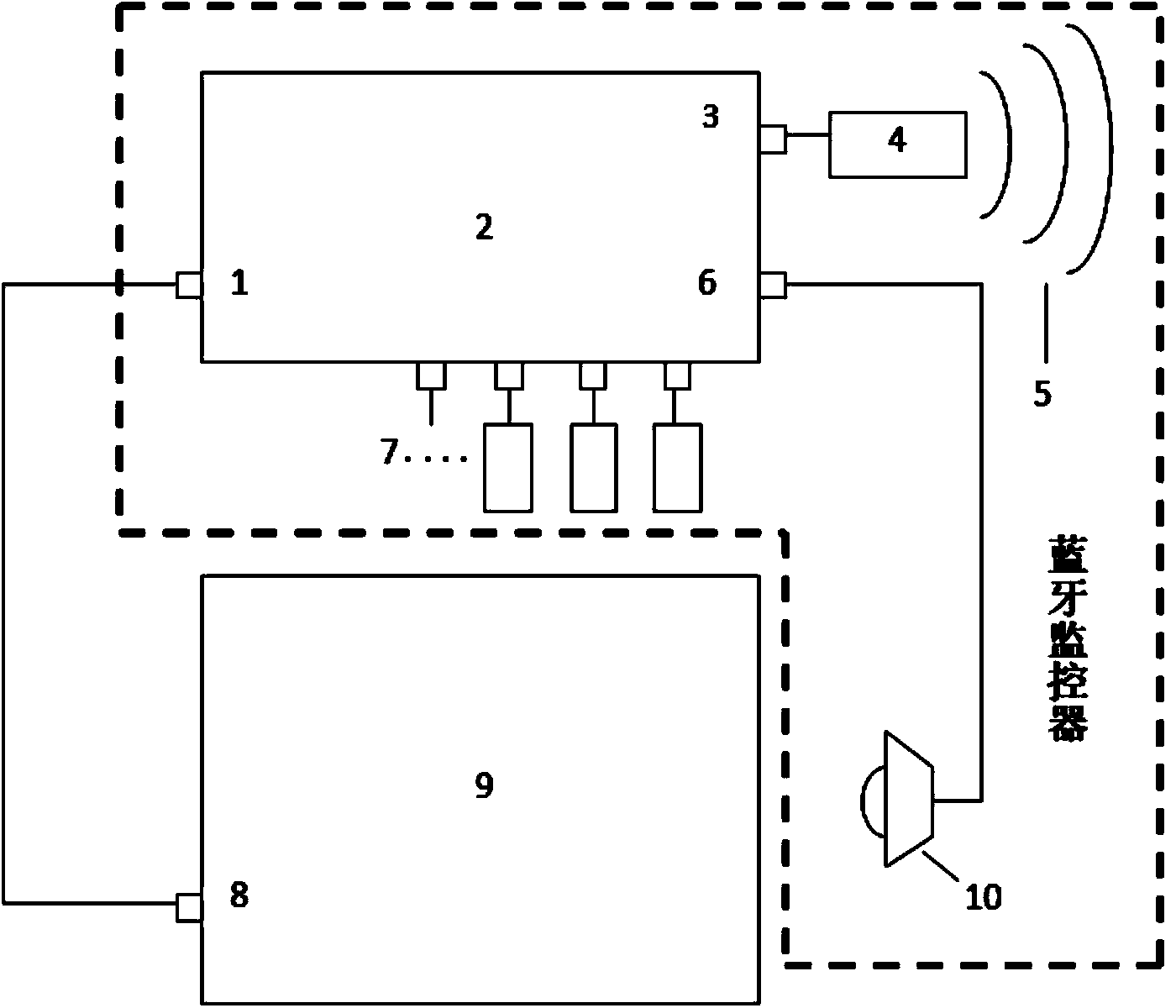

[0031] Such as figure 2 The Bluetooth monitor includes an environmental data collection module, data processing, 2 and a Bluetooth serial port module 4 connected in sequence, wherein the data processing board 2 is connected to the 3D printing device 9 through the serial port 1 and the interface 8, and the Bluetooth serial port module 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com