Three-point bending testing system based on dynamic fracture toughness of testing material

A technology of fracture toughness and three-point bending, which is applied in the field of three-point bending test system, can solve the problems of device system work flexibility discount, complex assembly, bulky overall structure, etc., to ensure self-mobility and adjustability, and ensure fixed point The effect of force resistance and great operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] combine here Figure 2-19 Concrete structure and workflow of the present invention are described as follows:

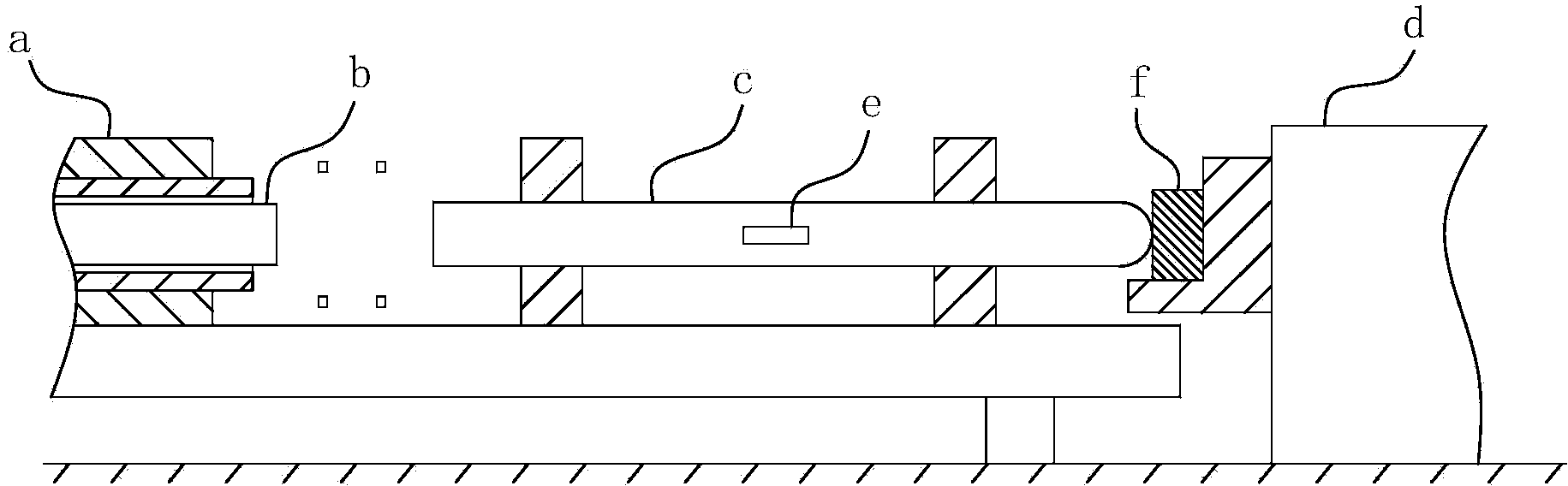

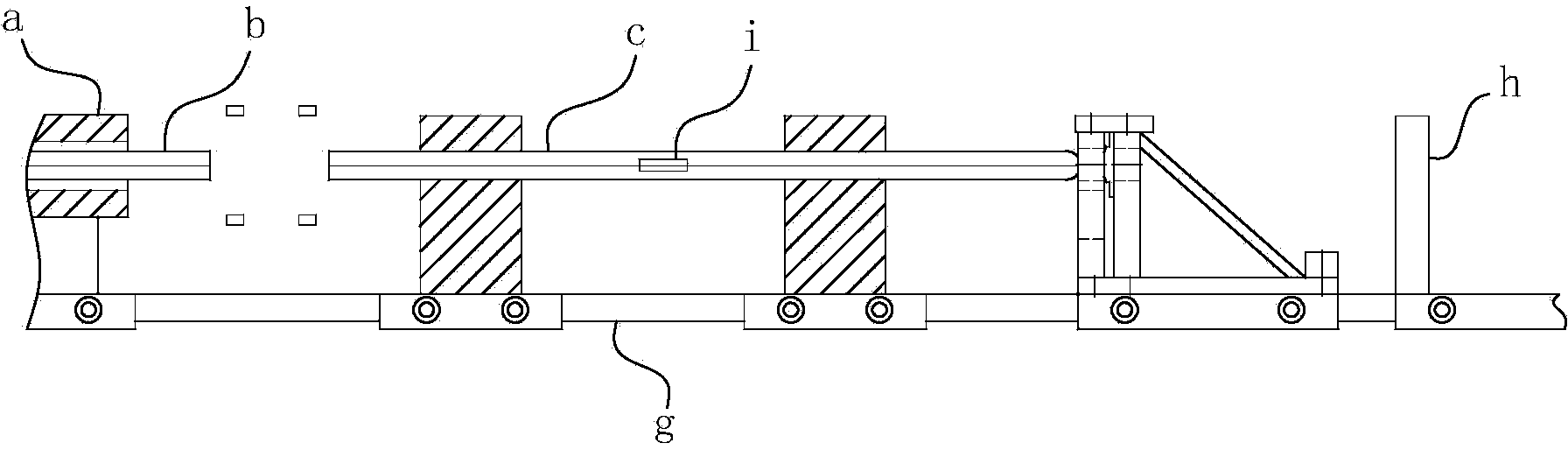

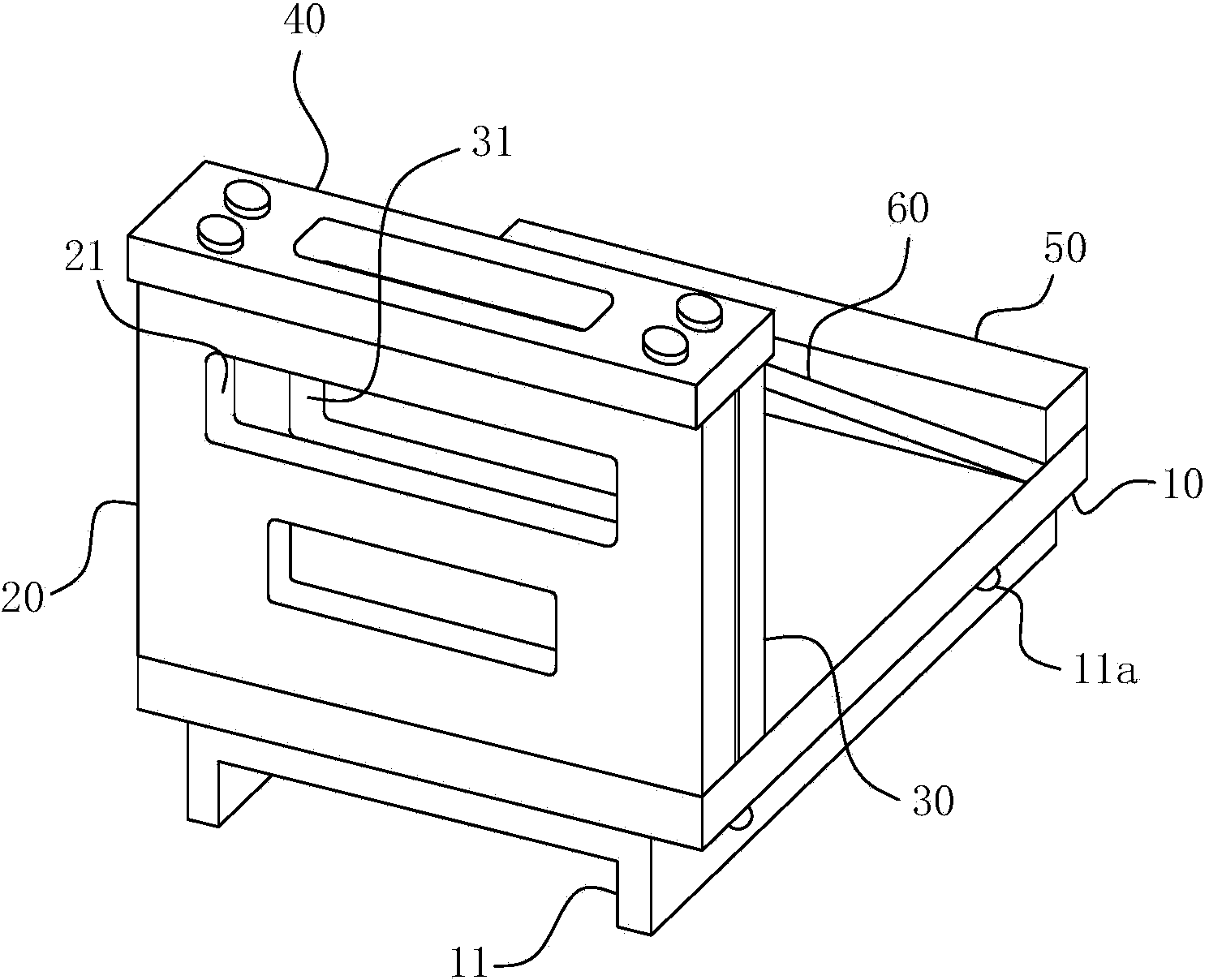

[0049] Concrete structure of the present invention, can refer to figure 2 As shown, it includes a base, on which a guide rail part g is arranged along the impact direction of the loading rod c, and on the guide rail part g, the air gun a, the striking rod b, the loading rod c, the supporting device and the baffle part h are arranged in sequence, wherein the striking rod b is arranged concentrically with the loading rod c, the support device is used to place and fix the test sample, the baffle part h is used to stop the loading rod c, the test system also includes an external information collection and processing device, and the information collection and processing device is equipped with an induction sheet i, the induction piece i is attached to the loading rod c. During the actual test, the compressed air gun a applies an instantaneous impulse to the impac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com