Plastic ceiling lamp base

A technology for ceiling lamps and lamp holders, which is applied to lighting devices, components of lighting devices, light source fixing, etc. It can solve the problems of inability to recycle, complex assembly process, high price, etc., and achieve light production cost and high processing technology. Simple, easy and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

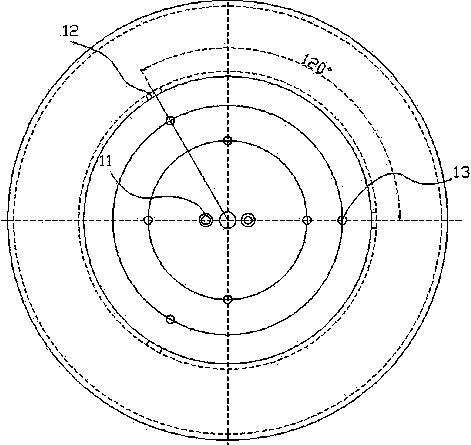

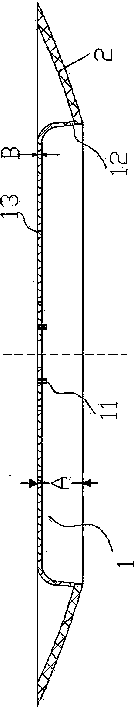

[0019] The invention discloses a plastic ceiling lamp holder, such as figure 1 , 2 As shown, the lamp holder and the transparent decorative cover are closely matched to form a complete energy-saving ceiling lamp shell. The lamp holder is made of PP plastic injection molding, which is characterized in that the radially outer high point and the bottom surface of the lamp holder form an arc surface 2, and the middle is made of There is a concave cavity 1, and screw holes 11 and positioning holes 13 are formed in the concave cavity 1, and three equal notches 12 are formed at the junction of the arc surface 2 and the concave cavity 1, and the equal notches 12 and the protrusions of the decorative lamp cover are formed. Very fit, the screw hole 11 in the concave cavity 1 can fix the pin of the 2D tube, and the positioning hole 13 is used for fixing the lamp pin of the play-shaped tube and the reflector of the LED lighting.

[0020] A plastic ceiling lamp holder of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com