Hot pressurized xenon filling method for satellite electric propulsion system

A thermal pressurization and electric propulsion technology, applied in the container filling method, container discharge method, equipment loaded into the pressure vessel, etc., can solve problems such as leaks, achieve high cleanliness, reasonable test methods, and comprehensive and complete measurement data Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

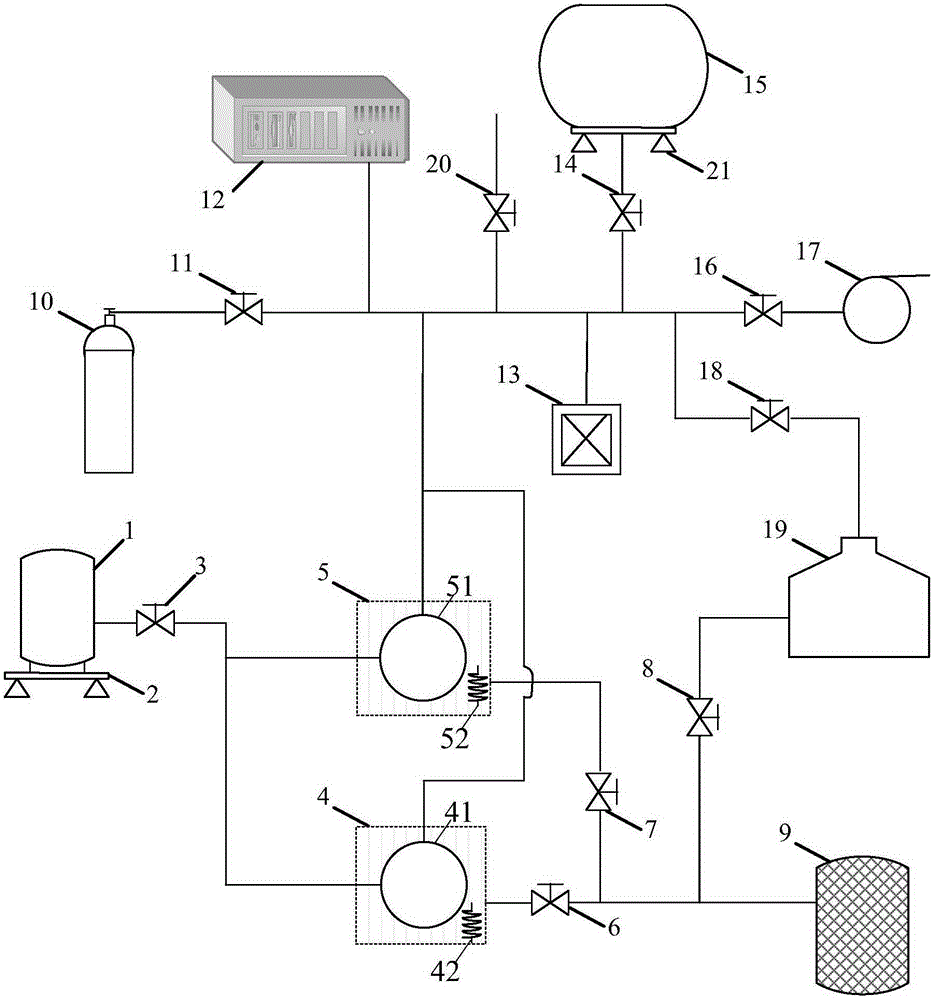

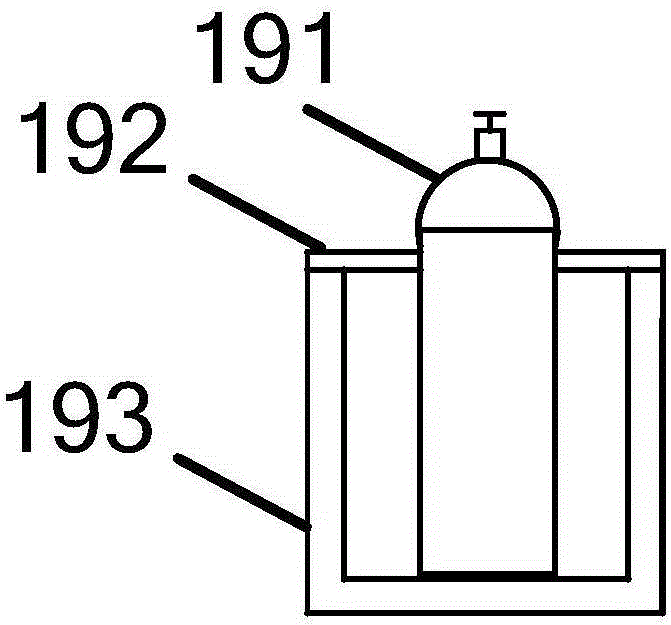

[0037] Such as figure 1 As shown, the system includes xenon gas storage tank 1, storage tank weighing electronic scale 2, gas source valve 3, thermal booster A4, thermal booster B5, liquid nitrogen valve A6, liquid nitrogen valve B7, liquid nitrogen valve C8 , liquid nitrogen tank 9, helium cylinder 10, helium valve 11, control and data acquisition module 12, purity analyzer 13, filling valve 14, star cylinder 15, vacuum valve 16, vacuum pump 17, recovery valve 18, Recovery module 19, deflation valve 20, gas cylinder weighing device 21 on the star.

[0038] The pipelines used for system connection are high-polished stainless steel high-pressure pipelines. The specific connection method is as follows: The xenon storage tank 1 is placed on the storage tank weighing electronic scale 2, and the high-pressure pipeline is used to connect it with the gas source valve 3 and The thermal booster device A4 and the thermal booster device B5 are connected; the liquid nitrogen tank 9, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com