Gob-side entry retaining method of fully-mechanized mining/full-mechanized caving mining working face

A fully-mechanized caving face and back mining face technology, which is applied to mining equipment, earthwork drilling, pillars/brackets, etc., can solve the problems of high labor intensity, large air leakage in goafs, and large wood consumption, etc., to achieve Extensive practicability, high support strength, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

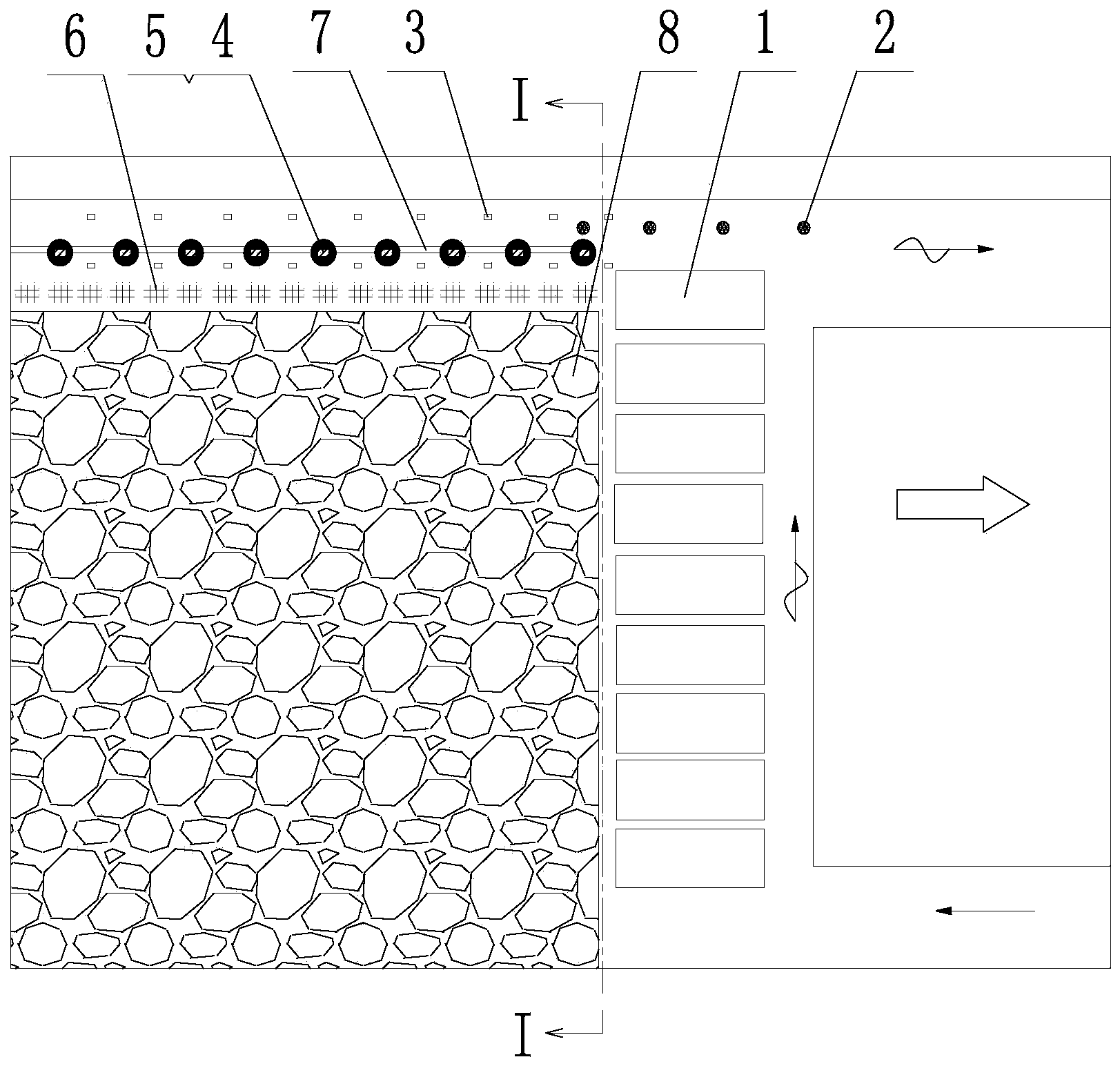

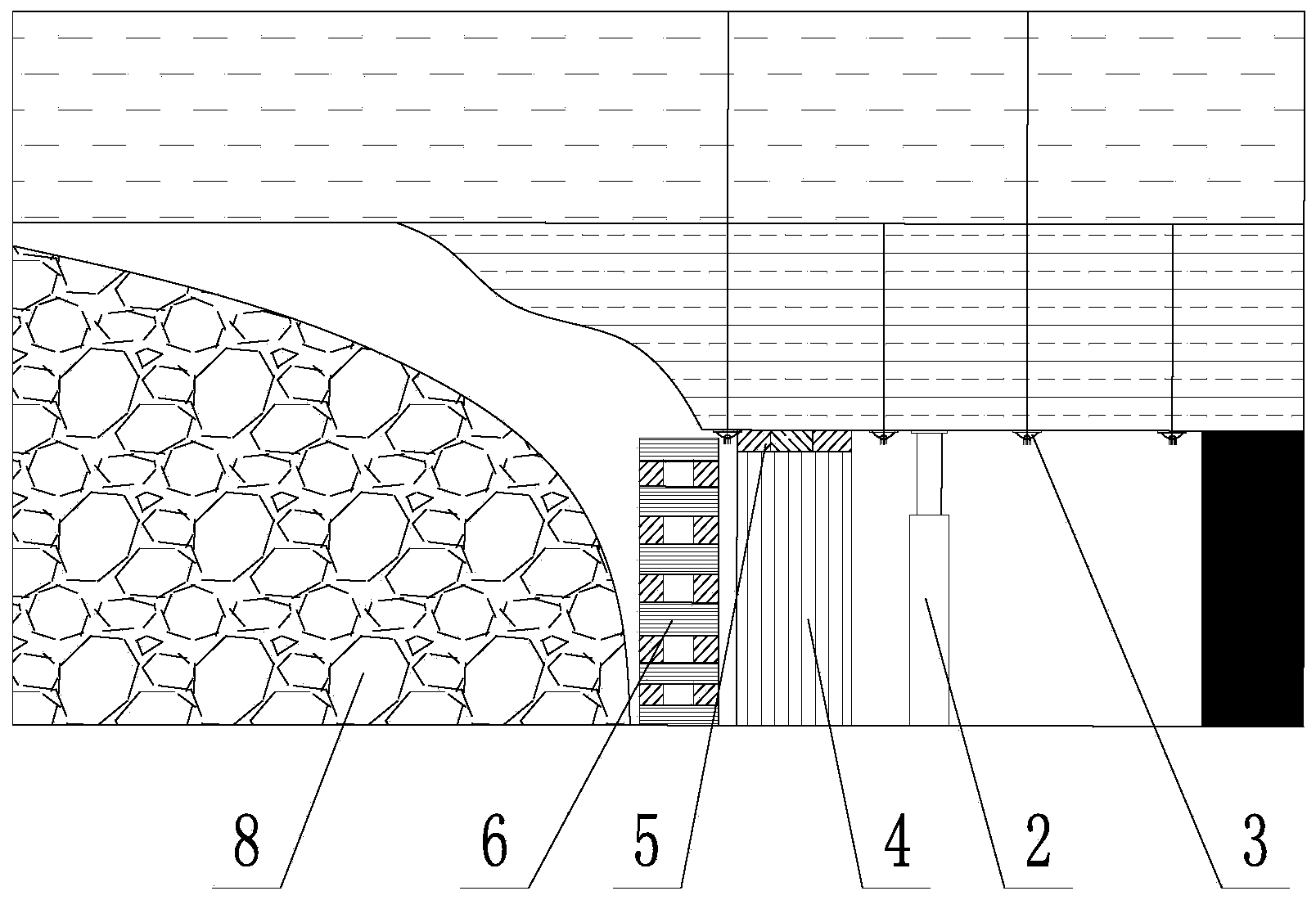

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] The method for retaining gobside entry in the fully mechanized mining / mechanized caving face specifically comprises the following steps:

[0025] Step 1: With the advance of the mining face in the coal mine underground roadway, the anchor cable or the anchor rod 3 is driven between the end hydraulic supports 1 of the mining face or at the roof behind the end hydraulic support 1, and the anchor cable is used to carry out When anchoring, choose an anchor cable with a length of 5m, and when using an anchor rod for anchoring, choose an anchor rod with a length of 2.5m;

[0026] Step 2: Determine the pre-installation position of the pier column 4, and install the single hydraulic prop 2 inside the pre-installation position of the pier column 4;

[0027] Step 3: install the pier column 4 by manual hoisting or mechanical operation, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com