A kind of continuous double hull reinforcement method for deep tunnel

A deep, deep grouting technology, applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve problems such as roadway repair rate and cost doubled, affecting deep coal resource mining, and increased cost of roadway primary support, etc. , to achieve the effects of good support effect, easy implementation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

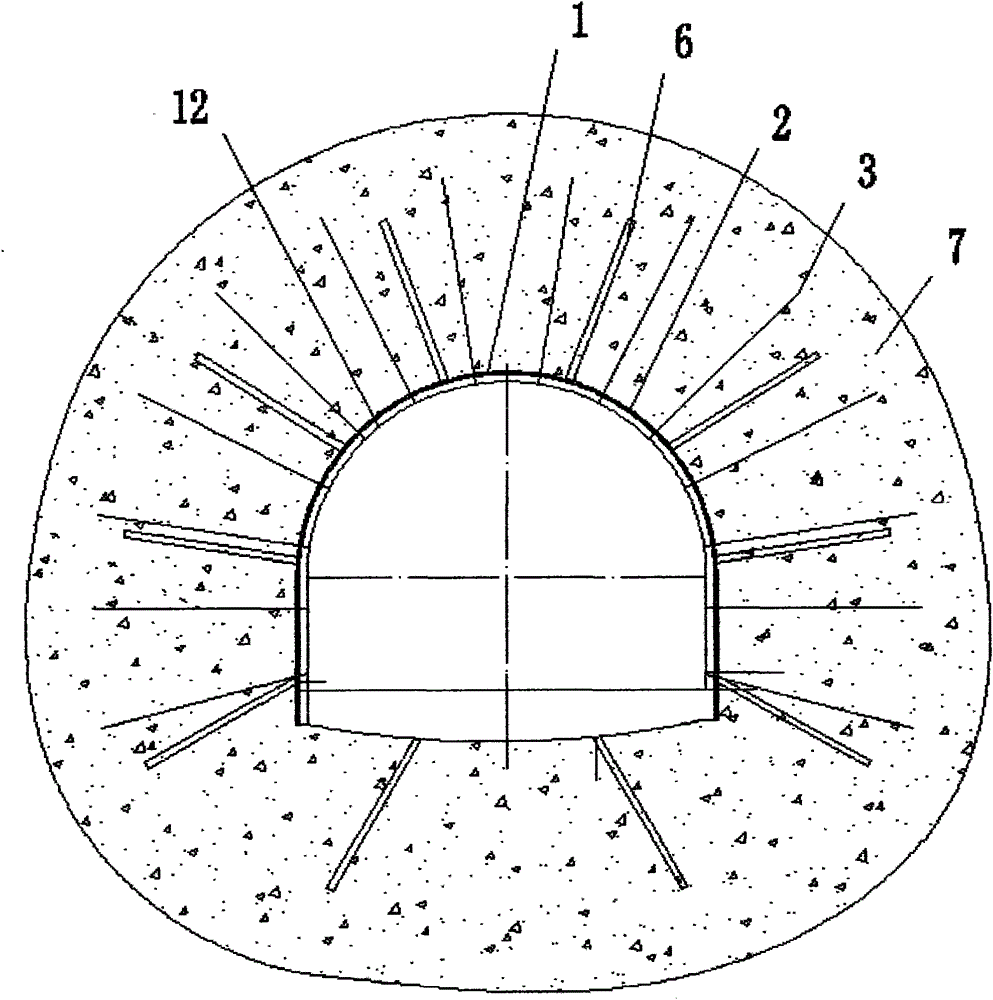

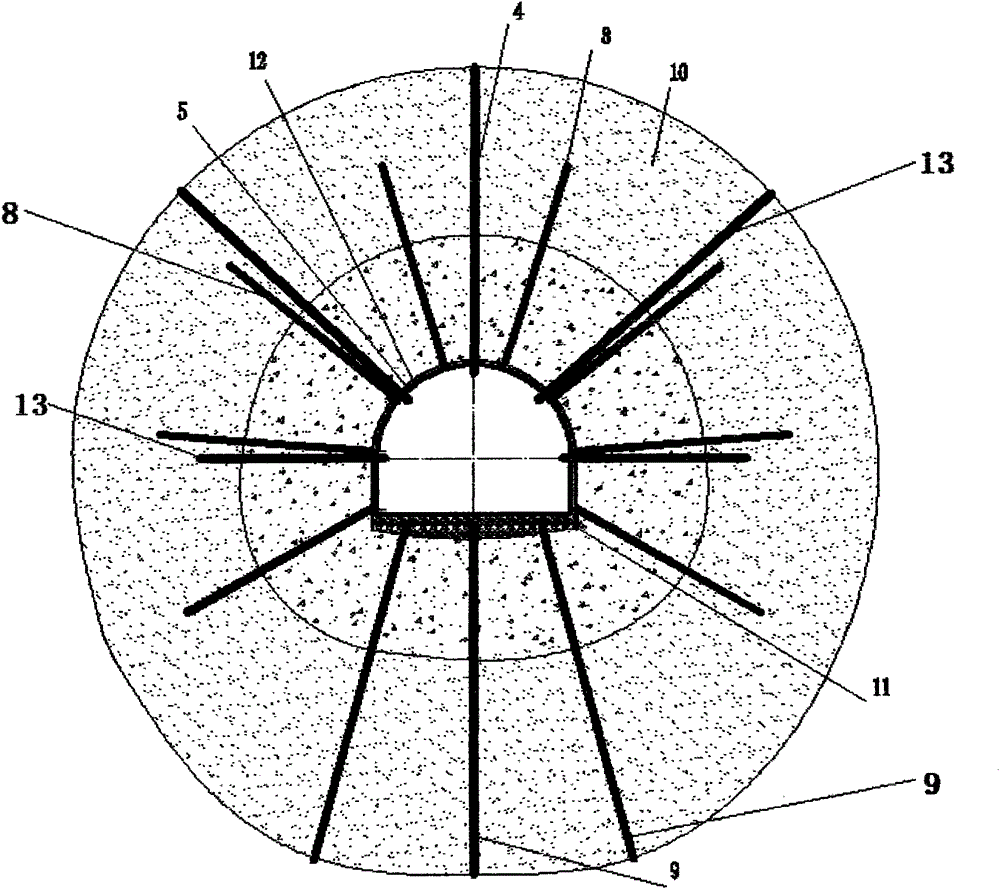

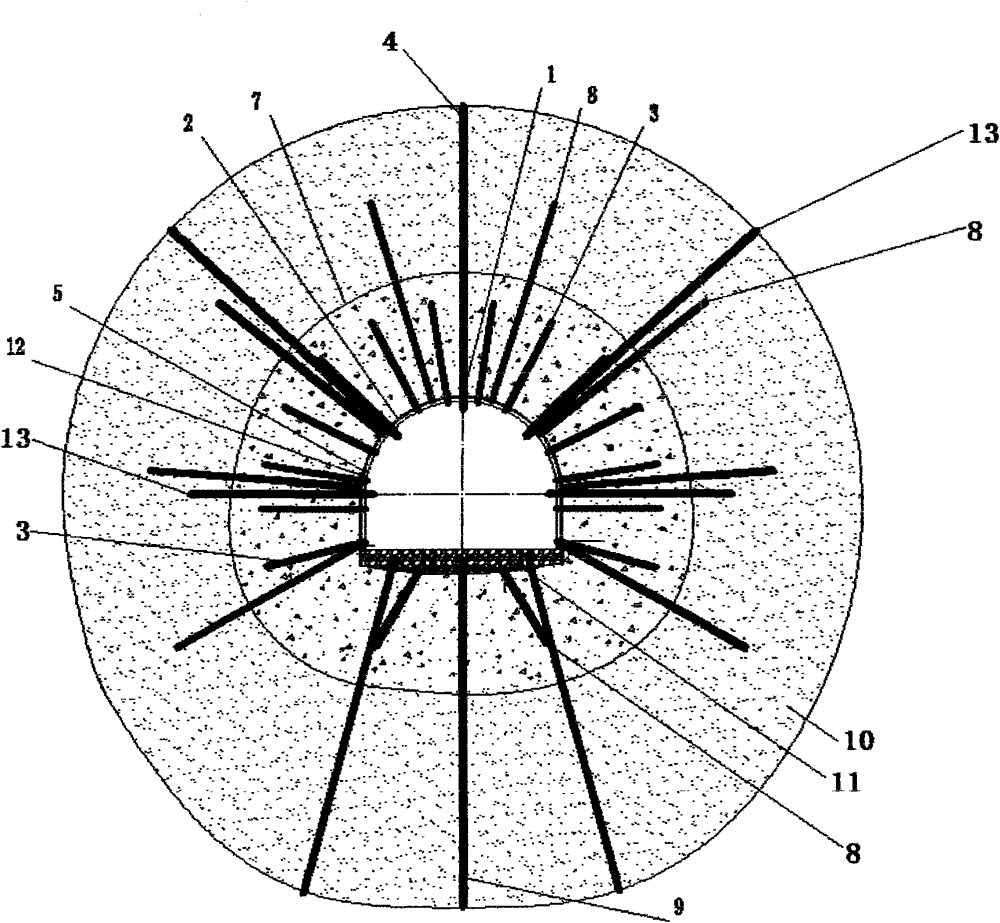

[0024] Such as figure 1 , 2 , Shown in 3, a kind of deep tunnel continuous double-shell reinforcement method of the present invention comprises the following steps:

[0025] (1) Immediately after the roadway is excavated, the anchor spraying is carried out once for support. Firstly, the rough section 1 is excavated and the first concrete layer 2 is sprayed immediately, and then the anchor rod 3 is hung with a net and a top anchor cable 4 is laid in the center of the roadway roof. Help the anchor cable 13 around the roadway;

[0026] (2) Secondary support is implemented at the lagging head 30-40m, the top anchor cable 4 and the side anchor cable 13 are repaired, and the second concrete layer 5 is re-sprayed;

[0027] (3) 1 to 2 days after the respraying of the second concrete layer 5, the first grouting hole 6 with a depth of 1.5 to 2 m is drilled on the full section, and the grouting pipe is installed to perform shallow grouting to form a shallow grouting reinforcement shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com