Gas feeding device, reaction cavity, and plasma processing equipment

A technology of reaction chamber and air intake device, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of reducing process uniformity and adjustment, so as to improve process uniformity, uniform distribution, The effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solution of the present invention, the gas inlet device, reaction chamber and plasma processing equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

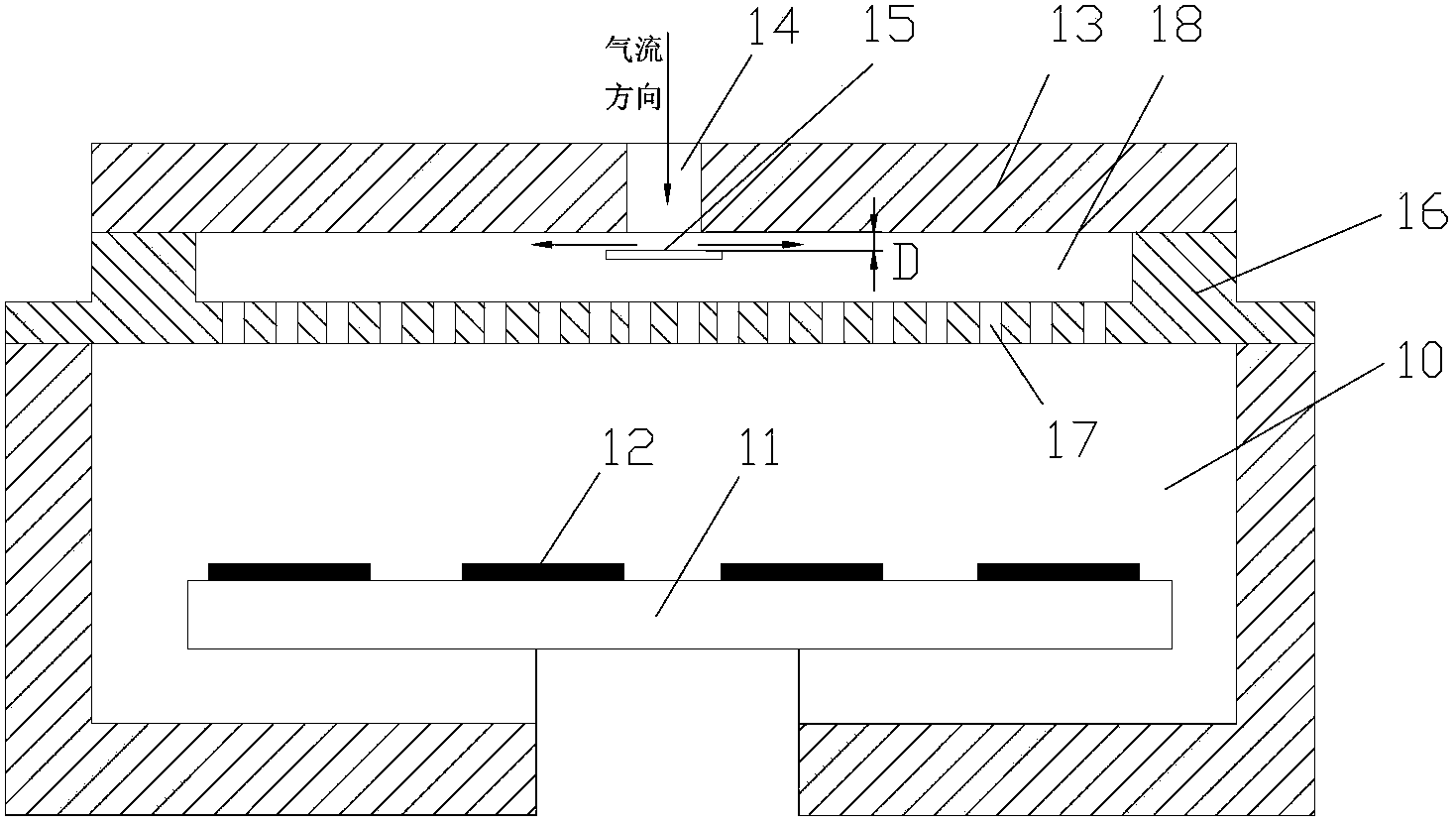

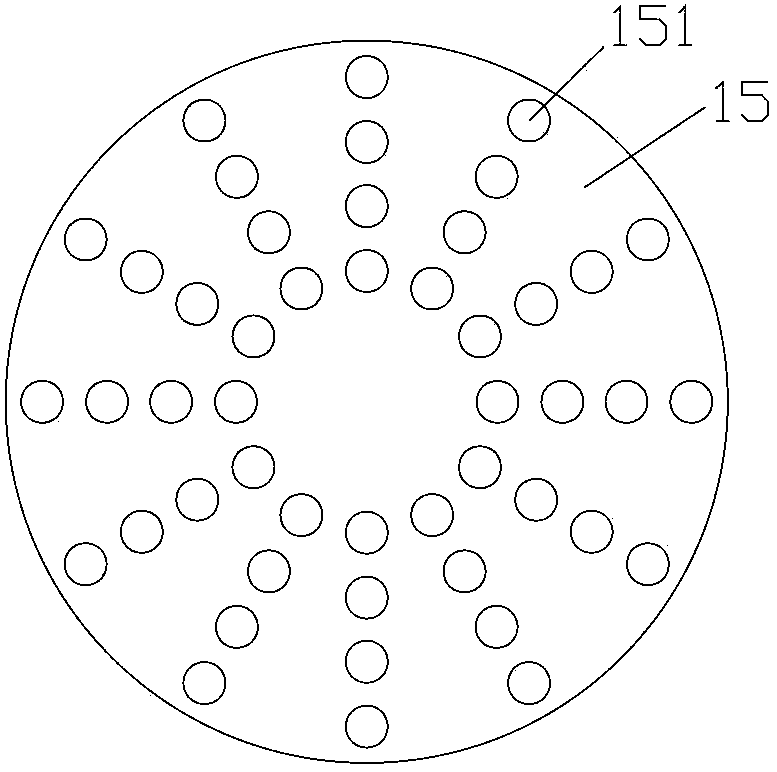

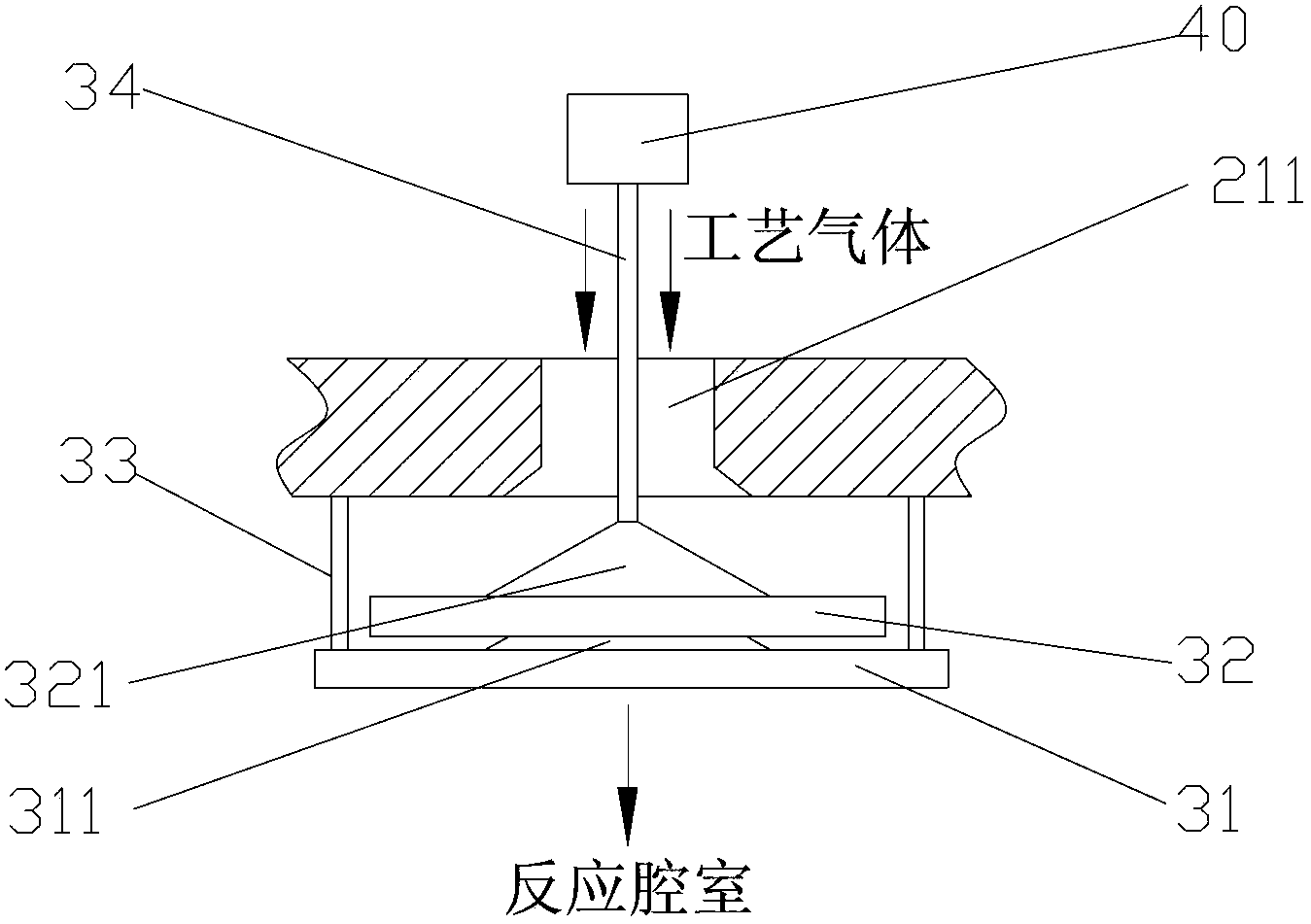

[0037] image 3 It is a schematic structural diagram of the air intake device provided by the first embodiment of the present invention. Figure 4A for image 3 The top view of the two diffusers in the air intake device shown when the through holes of the two are completely overlapped. Figure 4B for image 3 The top view of the two diffuser plates in the shown air intake device when the through holes of the two plates intersect each other. Please also refer to image 3 , Figure 4A and Figure 4B , the air inlet device is used to deliver process gas to different areas inside the reaction chamber, which includes a central air inlet 211 , a diffuser plate unit, a first d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com